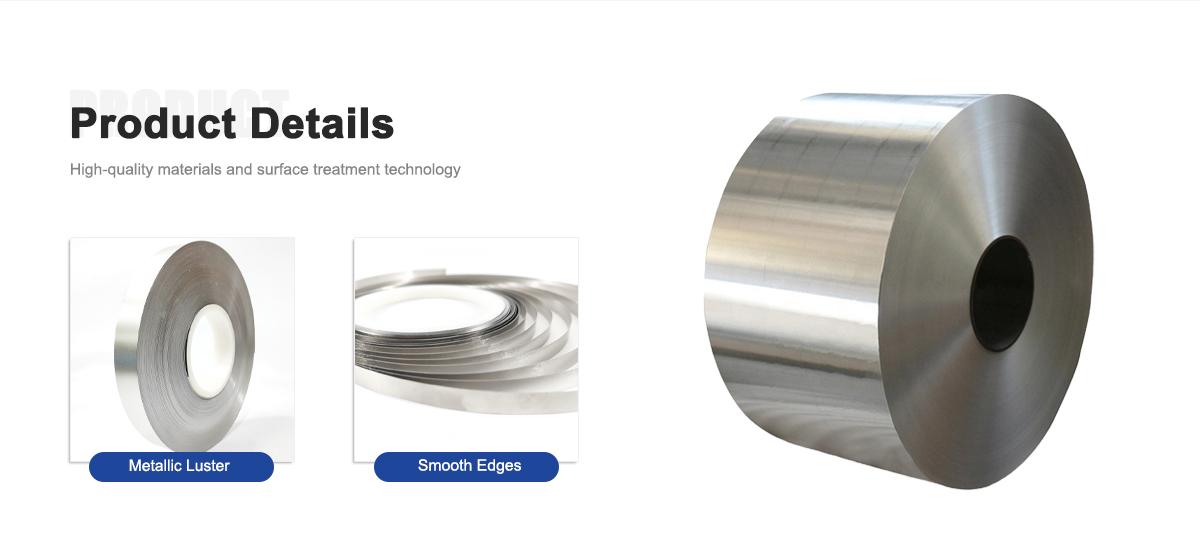

Incoloy 800H Strip for Petrochemical Heat Exchanger Durability

Our Incoloy 800 H strip is the ultimate choice for petrochemical heat exchanger durability. Made from a nickel-iron-chromium alloy, this strip is engineered to withstand high temperatures, carburizing environments, and oxidation without breaking a sweat. It’s perfect for heat exchanger components, gaskets, and seals in petrochemical plants. Easy to form, weld, and cut, it offers excellent creep and stress rupture resistance, ensuring your equipment stays reliable under intense conditions. Our strip is built to keep your systems running strong for the long haul.

For more details, pls directly contact us.

The petrochemical industry is booming, with global demand for high-performance materials on the rise. Stricter environmental regulations and the need for efficient, long-lasting equipment are driving plants to upgrade their heat exchangers. The oil and gas sector, along with chemical processing, is expanding, especially in emerging markets, creating a huge need for durable alloys. Trends show a shift toward materials that handle extreme heat and corrosion while cutting maintenance costs. Our Incoloy 800H strip is leading the way, delivering unmatched durability in a competitive market.

Parameter | Incoloy 800H Strip | Other Nickel Alloys | Stainless Steel |

|---|---|---|---|

High-Temperature Resistance | Excellent for prolonged high-heat exposure | Good, but varies by alloy, some weaken faster | Limited, degrades under extreme heat |

Corrosion Resistance | Strong in carburizing and oxidizing environments | Moderate, varies by alloy | Poor, corrodes in harsh petrochemical settings |

Creep/Stress Rupture Resistance | Superior for long-term high-temperature use | Moderate, depends on alloy | Poor, prone to creep and rupture |

Fabrication Ease | Easy to form, weld, and cut | Moderate, some alloys harder to work with | Easy, but corrosion limits applications |

Oxidation Resistance | Outstanding in high-temperature oxidation | Good, but less consistent | Moderate, weaker in oxidizing conditions |

Durability | Extremely durable, long service life | Moderate to high, depends on alloy | Moderate, shorter lifespan in harsh settings |

Chemical Versatility | Good for carburizing and some acid environments | Varies, less versatile in some cases | Limited, fails in aggressive chemicals |

Cost-Effectiveness | Higher upfront cost, long-term savings | Varies, some cheaper but less durable | Low cost, but frequent replacements needed |

Our Incoloy 800H strip is built for tough petrochemical jobs:

Petrochemical: Ideal for heat exchanger components and gaskets in high-temperature systems.

Power Generation: Perfect for steam generators and high-heat piping.

Chemical Processing: Reliable for equipment in carburizing and oxidizing environments.

Oil and Gas: Tough enough for refinery systems exposed to harsh conditions.

Industrial Furnaces: Stands up to extreme heat and cyclic temperatures.

This strip is your go-to for systems where high-temperature durability is critical.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Our Incoloy 800H strip stands out because we’re all about quality and performance. We manufacture to strict ASTM standards, ensuring top-tier heat and corrosion resistance. Every strip goes through rigorous in-house testing to handle the toughest petrochemical environments. Our large inventory and fast delivery keep your projects on schedule, and we offer custom sizes to fit your exact needs. Our expert team supports you from selection to installation. While others might cut corners, we deliver strip that lasts, saving you downtime and replacement costs.

Conclusion

For petrochemical heat exchanger durability, our Incoloy 800H strip is the smart pick. It combines superior high-temperature strength, corrosion resistance, and easy fabrication to meet the demands of modern petrochemical plants. With industry trends favoring durable, low-maintenance materials, our strip is built to exceed expectations. Trust us for quality, fast service, and a partner who understands your industry’s challenges.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why use Incoloy 800H strip for petrochemical heat exchangers?

It’s built to handle high temperatures and resist corrosion, ensuring long-lasting performance in tough petrochemical environments.What industries rely on Incoloy 800H strip?

Petrochemical, power generation, chemical processing, and oil and gas industries depend on its durability.Can Incoloy 800H strip withstand extreme heat?

Absolutely, it’s designed for high-temperature stability, perfect for heat exchanger applications.Is Incoloy 800H strip easy to fabricate?

Yep, it’s easy to form, weld, and cut while maintaining its strength and corrosion resistance.What corrosives can Incoloy 800H strip resist?

It handles carburizing environments, oxidation, and some acids like a pro.How does Incoloy 800H strip perform against creep?

It’s top-notch at resisting creep and stress rupture, ideal for long-term high-temperature use.What’s the lifespan of Incoloy 800H strip in petrochemical systems?

With proper care, it can last decades, outlasting less durable materials.Is Incoloy 800H strip cost-effective?

Its durability and low maintenance make it a smart choice for high-heat applications.