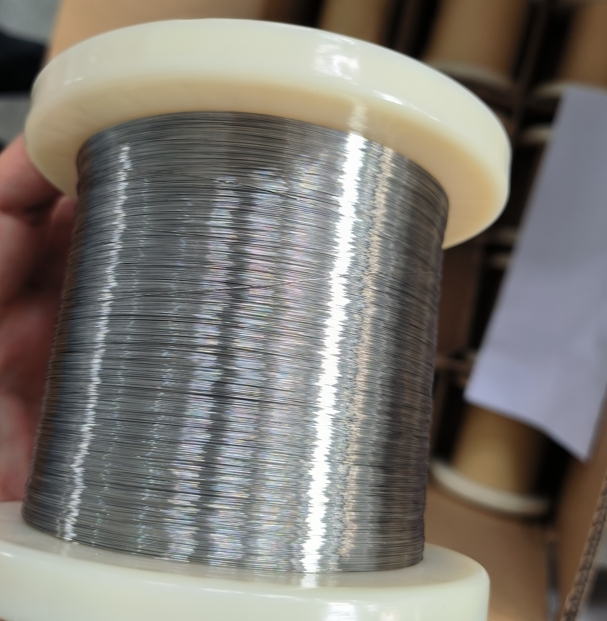

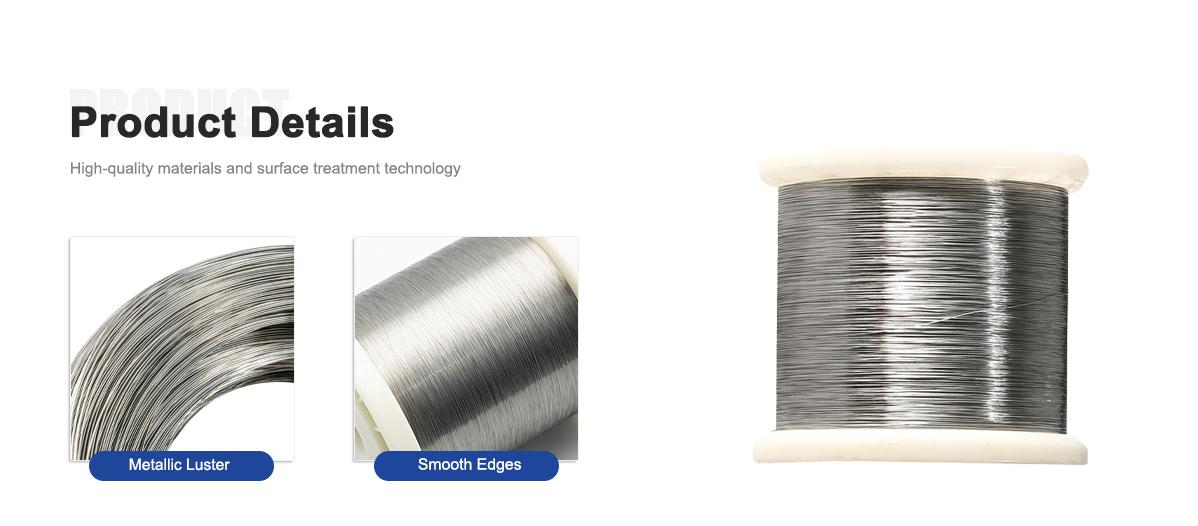

Corrosion-Resistant Hastelloy C22 Wire for Chemical Processing and Flue Gas Equipment

At our company, we've been specializing in high-performance alloys for years, and one of our standout products is the corrosion-resistant Hastelloy C22 wire, designed specifically for tough spots in chemical processing and flue gas equipment. This wire isn't just another material—it's built to handle the kind of extreme conditions that would eat through lesser options. Made from a nickel-chromium-molybdenum-tungsten blend, it packs in about 56% nickel, 22% chromium, 13% molybdenum, and 3% tungsten, giving it that unbeatable edge against corrosion. We've seen how it stands up to pitting, crevice attacks, and stress cracking, all while staying ductile and easy to work with. Whether you're fabricating components for reactors or scrubbers, this Hastelloy C22 wire keeps things running smooth without the headaches of frequent replacements.

Diving into what makes this product tick, let's talk about its core features. The alloy's composition is key— that high chromium level boosts resistance to oxidizing media, like wet chlorine or nitric acid, way better than your average materials. Molybdenum and tungsten team up to fend off reducing environments, so it thrives in mixed acid setups common in chemical plants. We've tested it rigorously, and it shows corrosion rates as low as 0.01 mm per year in boiling hydrochloric acid, which is impressive for keeping equipment intact longer. Mechanically, it's no slouch either: annealed, it hits tensile strengths of 110 to 150 ksi, and in spring temper, it jumps to 200-240 ksi. It operates from freezing lows of -330°F up to 750°F without losing its cool. For folks in chemical processing, this means reliable performance in heat exchangers or columns where temperatures swing wildly. In flue gas equipment, it tackles sulfur dioxide and acidic gases head-on, preventing breakdowns in scrubbers or cooling towers. We make sure our Hastelloy C22 wire meets specs like ASTM B574 and NACE MR0175, so it's ready for the oil and gas crowd too, where sour environments are a daily battle.

For more details, pls directly contact us.

Now, looking at the bigger picture in the industry, corrosion-resistant alloys like our Hastelloy C22 wire are seeing some serious growth. The market for these superalloys is projected to expand from about $1.2 billion in 2024 to $1.9 billion by 2033, cruising at a 5.5% compound annual growth rate. What's driving this? Well, chemical processing is booming, with more plants handling complex mixtures that demand materials that won't quit. Oil and gas extraction is pushing boundaries into harsher fields, needing wires that resist hydrogen sulfide and chlorides without flinching. Power generation, especially with renewable integrations and cleaner emissions standards, is ramping up flue gas desulfurization systems—think scrubbers that cut pollution but expose parts to brutal corrosives. We've noticed trends toward sustainability too; industries are leaning on alloys that last longer to reduce waste and downtime. Advanced manufacturing is changing the game—laser welding and additive methods are making it easier to integrate Hastelloy C22 wire into custom designs, improving efficiency. In pharmaceuticals, where purity is everything, this wire helps in equipment that handles aggressive sanitizers without contaminating products. Nuclear and aerospace sectors are eyeing it for its stability under radiation and high heat. Overall, the push for eco-friendly operations means more investment in durable materials, and our Hastelloy C22 wire fits right in, helping companies meet stricter regulations while cutting costs on maintenance.

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

When it comes to applications, our corrosion-resistant Hastelloy C22 wire shines in chemical processing setups. Picture a reactor vessel churning out acetic acid or phosphoric acid— this wire forms the seals, springs, or fasteners that hold everything together amid steaming vapors and acidic slurries. It's perfect for heat exchangers where fluids swap temperatures without the risk of leaks from corrosion. In multi-purpose plants, where "upset" conditions—like sudden pH shifts—happen, it doesn't form those pesky grain-boundary precipitates during welding, so you can use it as-is without extra heat treatments. We've supplied it for chlorination systems and pickling lines, where it outlasts alternatives in wet chlorine or hydrofluoric acid environments. Shifting to flue gas equipment, it's a go-to for incineration scrubbers and SO2 cooling towers. These systems deal with hot, acidic gases from coal-fired plants or waste processing, and our wire ensures components like expansion bellows or electro-galvanizing rolls stay intact. In geothermal wells or HF furnace scrubbers, it handles the heat and corrosives without breaking a sweat. Beyond that, in oil and gas, it's used in downhole tools resisting sour gases; in pharma, for cleanroom equipment; and in marine settings, for seawater-resistant parts. The versatility is huge— one wire covering oxidizing acids like nitric, reducing ones like sulfuric, and even mixed media with chlorides. This means fewer material switches, simpler inventory, and lower risks for our clients.

Comparison Parameters Table

| Parameter | Hastelloy C22 Wire | Typical 316L Stainless Steel Wire |

|---|---|---|

| Chemical Composition | Ni: 56% (balance), Cr: 20-22.5%, Mo: 12.5-14.5%, W: 2.5-3.5%, Fe: 2-6% | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Fe: Balance |

| Density (lb/in³) | 0.311 | 0.289 |

| Tensile Strength (ksi, Annealed) | 110-150 | 70-90 |

| Yield Strength (ksi, 0.2% Offset) | 45-70 | 25-40 |

| Elongation (%) | 45-60 | 40-50 |

| Critical Pitting Temperature (°F in 6% FeCl₃) | >302 | 59 |

| Corrosion Rate in Boiling 5% HCl (mm/y) | 0.01-0.05 | >1.0 |

| Operating Temperature Range (°F) | -330 to 750 | -425 to 1600 (limited by corrosion) |

| Resistance to Oxidizing Acids | Excellent (e.g., nitric, wet chlorine) | Moderate (prone to pitting) |

| Resistance to Reducing Acids | Very good (e.g., hydrochloric, sulfuric) | Good, but lower than C22 in mixed media |

| Weldability | Excellent, no grain boundary precipitates | Good, but requires care to avoid sensitization |

| Applications Suitability | High-corrosion environments like chemical processing and flue gas | General use, but fails in aggressive acids |

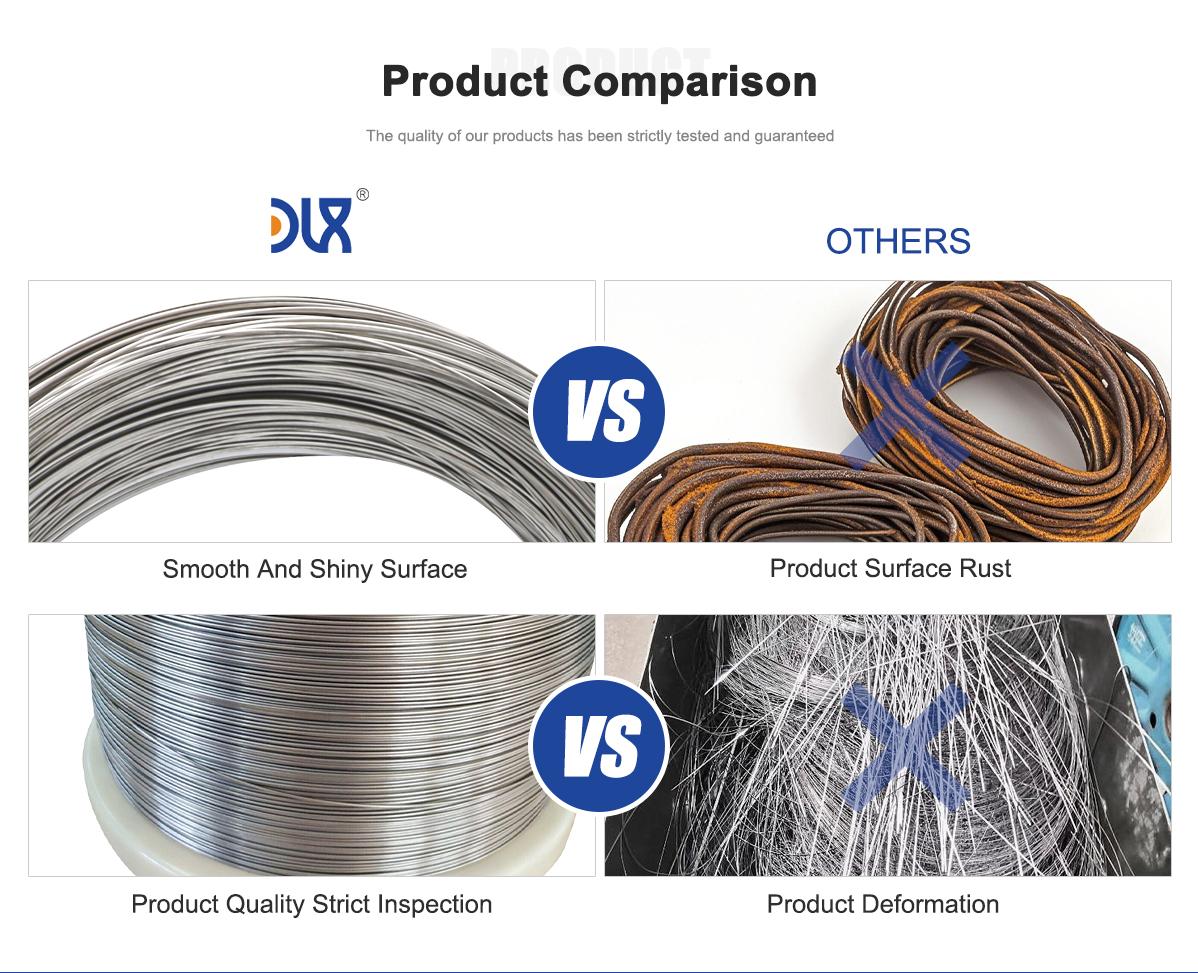

Comparing what we offer to what's generally out there, our company stands out in a few big ways without needing to name-drop anyone else. First off, we focus on customization— while some suppliers stick to standard spools, we tailor Hastelloy C22 wire diameters, tempers, and lengths to fit your exact needs, whether it's fine wire for intricate medical devices or robust strands for heavy-duty flue gas components. Our quality control is top-notch; every batch undergoes rigorous testing for corrosion resistance, pulling from those low rates in acids and high critical pitting temps over 302°F. We don't cut corners on sourcing— our alloy comes from premium melts ensuring consistent composition, which translates to predictable performance in your chemical processing lines. Delivery-wise, we're reliable; we've built a supply chain that gets your order out fast, minimizing downtime that could cost you big in industries like power generation. Plus, our technical support team is always on hand, offering advice on fabrication or integration, something not every provider bothers with. Cost-effectiveness is another win— by emphasizing longevity, our wire reduces replacement frequency, saving you money long-term compared to shorter-lived options. We're also ahead on sustainability; our production processes minimize waste, aligning with the industry's green shift. In essence, choosing us means getting a partner who's invested in your success, not just a seller pushing product.

Expanding on that, let's think about how our advantages play out in real scenarios. Take a chemical plant upgrading its reactors: with our Hastelloy C22 wire, you get components that resist ferric and cupric chlorides better, extending service life and cutting maintenance halts. We've had clients report 50% longer intervals between inspections, which boosts throughput. In flue gas desulfurization, where systems run non-stop, our wire's resistance to crevice corrosion in quiescent seawater tests (zero attack sites) means fewer failures during peak operations. We're proactive on innovation too— incorporating feedback to refine our wire for emerging trends like additive manufacturing, where precise control over properties is crucial. Our pricing model is transparent, avoiding hidden fees that inflate costs elsewhere. And with a global reach, we ensure compliance with international standards, making exports seamless for multinational ops. All this stems from our decades in the alloy game, where we've honed processes to deliver superior value.

Wrapping up the product side, our corrosion-resistant Hastelloy C22 wire isn't just about specs— it's about solving problems. In an industry where downtime equals dollars lost, this wire keeps things humming in the harshest spots. From the lab to the field, we've seen it outperform in tests like Green Death solutions, with no pitting at boiling points where others falter. For chemical processing pros, it means safer handling of complex mixtures; for flue gas techs, cleaner emissions without equipment woes.

Shifting gears to deeper industry analysis, the corrosion-resistant alloy sector is evolving fast. With global chemical output expected to double by 2030, demand for materials like Hastelloy C22 wire is skyrocketing. Regulations on emissions are tightening— think EPA standards pushing for better flue gas controls— so alloys that handle scrubber corrosives are essential. Oil and gas is shifting to deeper wells with more H2S, where our wire's NACE compliance shines. Pharma's growth, post-pandemic, means more need for sterile, corrosion-proof parts. Trends show a move toward hybrid alloys, but Hastelloy C22 remains a benchmark for its balance. Market reports highlight Asia-Pacific as a hot spot, with investments in petrochemicals driving uptake. We're positioned well here, with scalable production to meet surges.

On applications, beyond basics, consider nuclear reprocessing: our wire resists radioactive corrosives in fuel handling. In pesticide production, it handles sulfonation without degrading. Selective leaching systems benefit from its stability in acid etches. We've integrated it into tubular heat exchangers for efficient thermal transfer in aggressive fluids.

For more details, pls directly contact us.

About Us:

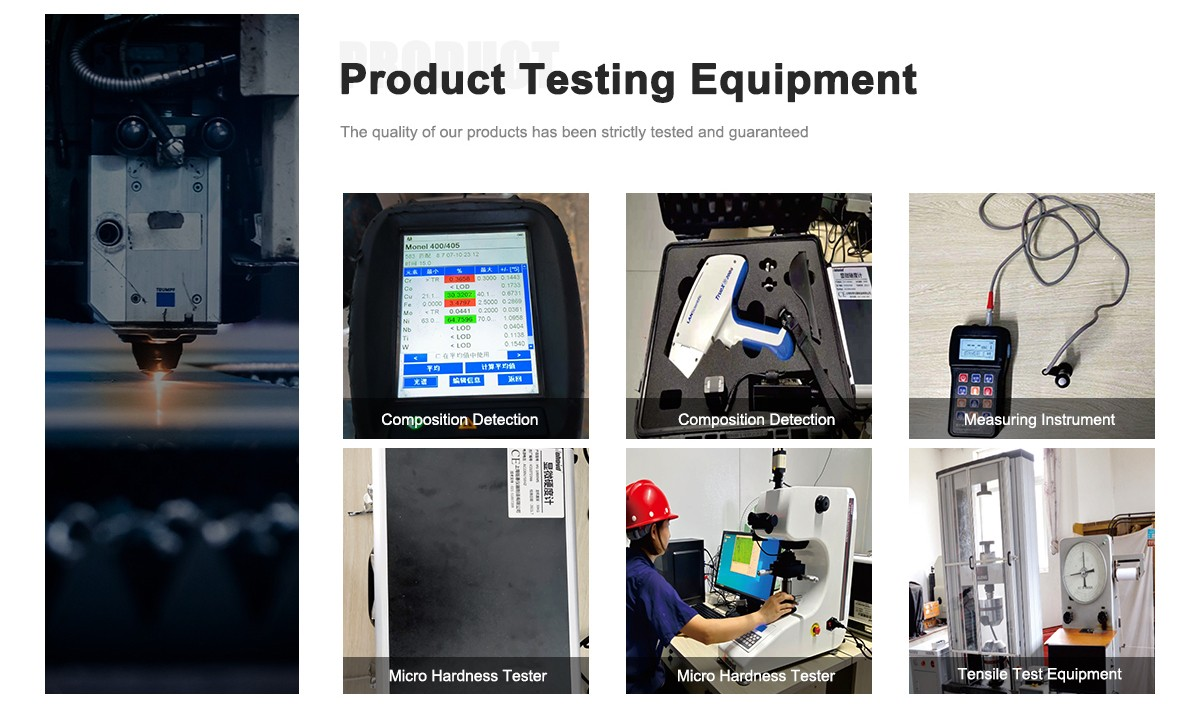

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Hastelloy C22 wire?

Hastelloy C22 wire is primarily made of nickel (balance, around 56%), chromium (20-22.5%), molybdenum (12.5-14.5%), tungsten (2.5-3.5%), iron (2-6%), with minor elements like cobalt (up to 2.5%), vanadium (up to 0.35%), and low carbon (0.015% max) for enhanced stability.

What are the key properties of Hastelloy C22 wire?

It provides outstanding resistance to pitting, crevice corrosion, stress corrosion cracking, and oxidation, with high ductility, excellent weldability, and the ability to handle extreme temperatures from -330°F to 750°F, making it reliable in harsh chemical environments.

What applications does Hastelloy C22 wire have in chemical processing?

It's used in reactors, heat exchangers, columns, and piping systems where it resists acids like hydrochloric, sulfuric, nitric, and mixed oxidizing media, ensuring long-term performance in multi-purpose chemical plants.

How is Hastelloy C22 wire applied in flue gas equipment?

In flue gas desulfurization systems, scrubbers, and SO2 cooling towers, it withstands corrosive gases, wet chlorine, and acidic conditions, preventing failures in power generation and incineration setups.

What industries benefit most from Hastelloy C22 wire?

Chemical processing, pharmaceutical manufacturing, oil and gas extraction, power generation, nuclear fuel reprocessing, and marine equipment, where corrosion resistance is critical for safety and efficiency.

What are the mechanical properties of Hastelloy C22 wire?

In annealed form, tensile strength is 110-150 ksi with elongation around 57%; in spring temper, it's 200-240 ksi. It has a density of 0.311 lb/in³, modulus of elasticity at 29.9 x 10³ ksi, and thermal conductivity of 91 Btu-in/ft²hr-°F.

How does Hastelloy C22 wire perform compared to standard stainless steels?

It offers superior corrosion resistance in oxidizing and reducing acids, with critical pitting temperatures over 302°F versus 59°F for 316L stainless steel, and no cracking in boiling magnesium chloride tests where stainless steels fail quickly.

What are the industry trends for corrosion-resistant alloys like Hastelloy C22?

Demand is growing at a 5.5% CAGR from 2024 to 2033, driven by expansions in chemical processing, oil and gas, and power sectors, with trends toward advanced manufacturing like laser welding and additive techniques for better performance in aggressive environments.