Stable Hastelloy C-4 Wire for High-Temperature Oxidizing Atmospheres and Stress-Corrosion Cracking

At DLX, we're all about delivering top-notch solutions for tough industrial challenges, and our Stable Hastelloy C-4 Wire for High-Temperature Oxidizing Atmospheres and Stress-Corrosion Cracking is a prime example of that. Let's dive into what makes this product a game-changer in the world of superalloys. As a team here at DLX, we've poured our expertise into crafting this wire to handle the harshest conditions, ensuring reliability where it counts most.

For more details, pls directly contact us.

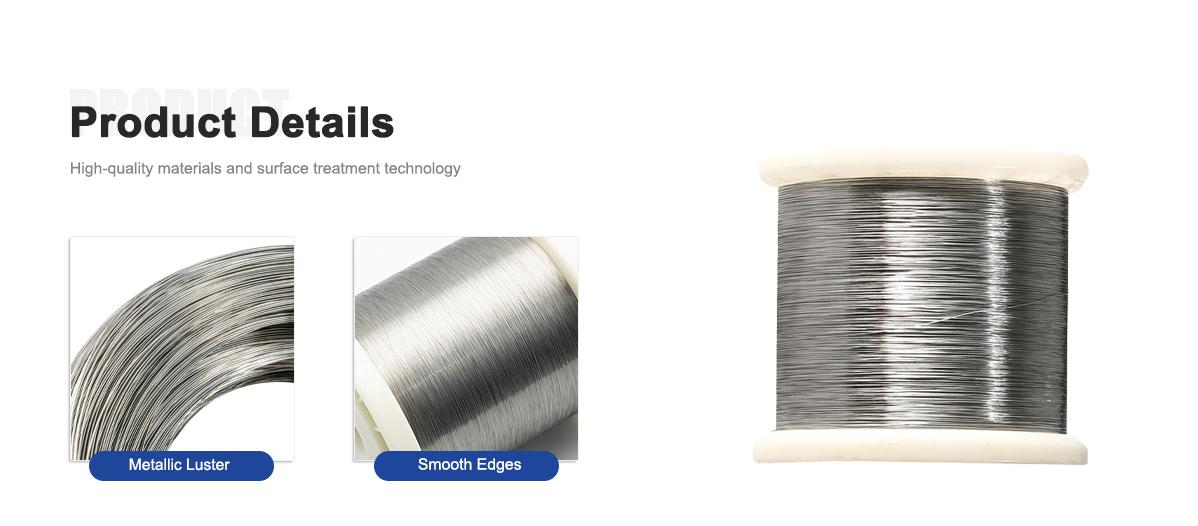

First off, let's talk about the product itself. Our Stable Hastelloy C-4 Wire is engineered from a premium nickel-chromium-molybdenum alloy, specifically UNS N06455, known for its incredible balance of strength and resistance. The composition—around 65% nickel, 16% chromium, and 16% molybdenum, with tight controls on impurities like carbon at just 0.01% max—gives it that edge in stability. Unlike some materials that falter under heat or corrosive attacks, this wire stays solid in high-temperature oxidizing atmospheres up to 1900°F. We've optimized it for applications where stress-corrosion cracking could spell disaster, making it ideal for environments loaded with chlorides, acids, or halides. At DLX, we produce this wire in various diameters, from fine gauges for intricate setups to heavier ones for structural needs, all with a focus on ductility and ease of fabrication. It's not just wire; it's a dependable partner for your projects, offering exceptional resistance to pitting, crevice corrosion, and uniform attack.

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Now, shifting gears to the broader industry landscape. The superalloy sector, particularly for corrosion-resistant materials like Hastelloy C-4 wire, is on an upward trajectory. We're seeing steady growth, with market projections pointing to a compound annual growth rate of about 3.8% through 2034, pushing the total value beyond $8 billion. What's driving this? Demand from chemical processing plants, oil and gas operations, marine engineering, and even emerging fields like renewable energy storage. As industries push for more efficient, longer-lasting equipment amid stricter environmental regs, alloys that can withstand extreme conditions without frequent replacements are in high demand. At DLX, we've noticed a spike in interest for high-temperature oxidizing atmospheres applications, where traditional stainless steels just can't keep up. Trends show a shift toward sustainable manufacturing too—recyclable alloys that reduce waste—and our Hastelloy C-4 wire fits right in, offering longevity that cuts down on material turnover. Plus, with global supply chains tightening, companies are looking for reliable domestic suppliers like us to avoid delays. We're positioning ourselves at the forefront by investing in advanced production techniques, ensuring our Stable Hastelloy C-4 Wire meets evolving standards for safety and performance.

When it comes to applications, our Stable Hastelloy C-4 Wire shines in scenarios that would chew through lesser materials. Take chemical processing, for instance—think reactors handling hydrochloric or sulfuric acids. This wire resists corrosion rates down to less than 0.1 mm per year in boiling solutions, keeping operations smooth without downtime. In pollution control systems, like scrubbers dealing with flue gases, its ability to handle oxidizing atmospheres at high temps prevents oxidation buildup, extending equipment life. We've supplied it for waste incineration setups where stress-corrosion cracking from chlorides is a real threat; our wire holds firm, reducing maintenance costs. Marine environments? Absolutely—offshore platforms exposed to saltwater and halides benefit from its pitting resistance, with critical pitting temperatures hitting 100°C. Even in pulp and paper mills, where bleaching processes involve aggressive chemicals, this wire ensures structural integrity. At DLX, we customize the wire for specific uses, whether it's welding filler for high-stress joints or components in heat exchangers. It's versatile, weldable without sensitization issues, and performs reliably in both oxidizing and reducing media.

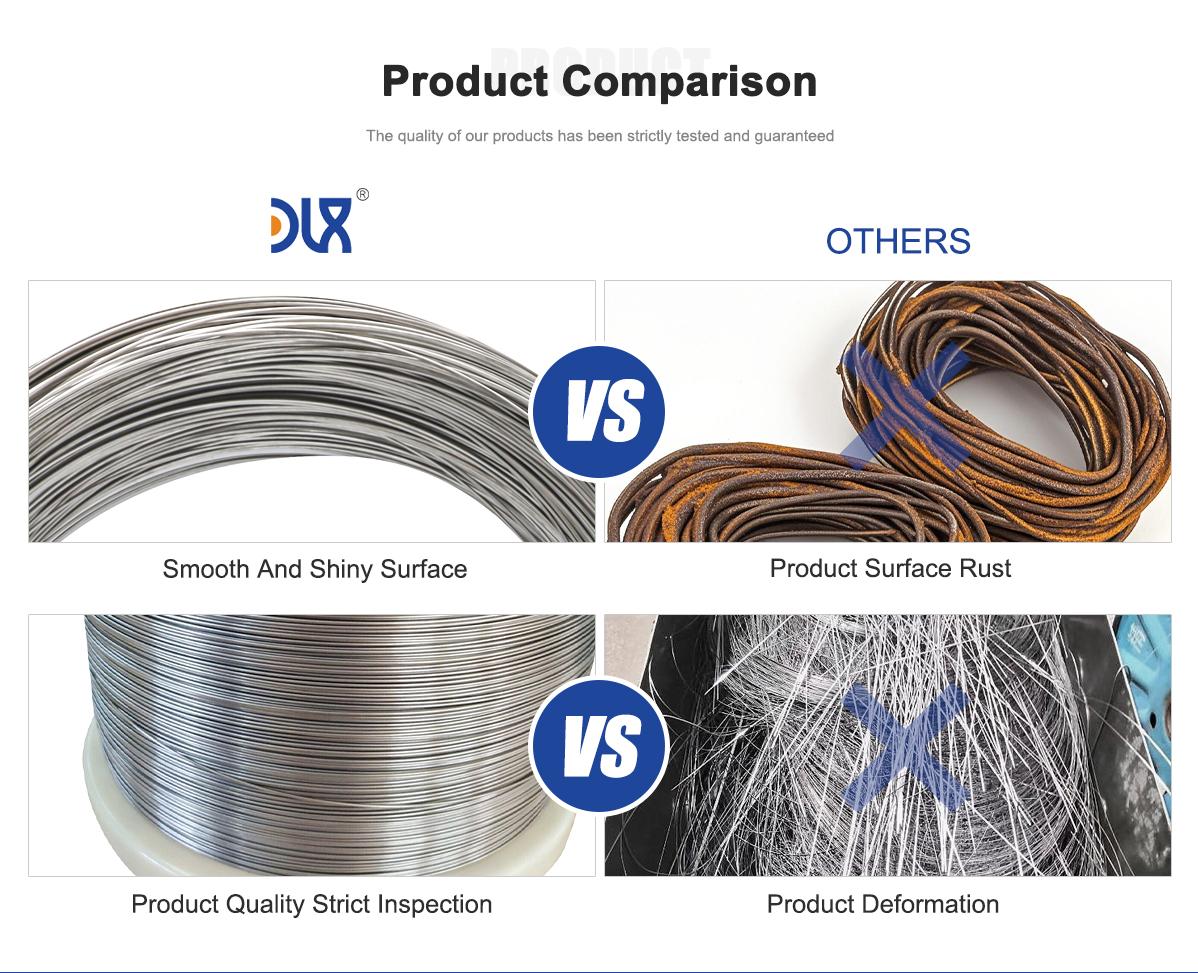

Of course, we can't ignore how our product stacks up in the market. While we won't name names, let's compare our DLX Stable Hastelloy C-4 Wire to what's generally available out there. Many alternatives lack the microstructural stability we achieve through precise alloying and processing. Our wire's thermal stability means it withstands welding heat without forming harmful precipitates—something that requires hours at 825°C for any noticeable effect, far better than typical offerings that sensitize quickly. This translates to easier fabrication and fewer failures in the field. In terms of corrosion resistance, our product excels in high-temperature oxidizing atmospheres, outperforming standard nickel alloys in acids above 5% concentration. We've got higher critical crevice temperatures at 50°C, reducing risks in chloride-heavy setups. Mechanically, it boasts a tensile strength of 111 ksi and elongation over 50%, ensuring it bends without breaking under stress. What sets DLX apart is our commitment to quality control—every batch is tested for consistency, something not always guaranteed elsewhere. We offer faster lead times, custom specifications, and expert support, helping clients integrate the wire seamlessly. Plus, our pricing reflects value, not just cost, with longevity that pays off over time. In short, choosing DLX means opting for superior performance without the headaches.

Comparison Parameters Table

| Parameter | Hastelloy C-4 | Hastelloy C-276 | Hastelloy C-22 |

|---|---|---|---|

| Nominal Composition | Ni 65%, Cr 16%, Mo 16%, Fe 3% max, Ti 0.7% max, C 0.01% max | Ni 57%, Cr 16%, Mo 16%, W 4%, Fe 5%, C 0.01% max | Ni 56%, Cr 22%, Mo 13%, W 3%, Fe 3%, C 0.01% max |

| Density (g/cm³) | 8.64 | 8.89 | 8.69 |

| Tensile Strength (ksi at RT) | 111 | 110 | 115 |

| Yield Strength (ksi at RT) | 60 | 52 | 55 |

| Elongation (%) | 52 | 60 | 62 |

| Max Operating Temp (°F) | 1900 | 1900 | 1900 |

| Corrosion Resistance | Excellent in oxidizing acids; superior thermal stability; resists SCC in chlorides | Broad resistance to reducing/oxidizing media; good in wet chlorine | Superior in oxidizing media; better pitting resistance than C-276 |

| Pitting Resistance (CPT °C) | 100 | 65 | 110 |

| Applications | Chemical processing, pollution control, high-temp oxidizing atmospheres | Flue gas desulfurization, pharmaceuticals, oil & gas | Wet chlorine processes, pulp bleaching, marine environments |

| Weldability | High thermal stability; minimal HAZ sensitization | Good, but more sensitive to heat input | Excellent, versatile in fabrication |

| Key Advantage | Best microstructural stability among Ni-Cr-Mo alloys | Versatile in mixed corrosive environments | Enhanced resistance to localized corrosion |

But let's get deeper into why our Stable Hastelloy C-4 Wire is built for high-temperature oxidizing atmospheres. Oxidation at elevated temps can degrade materials fast, leading to scaling or embrittlement. Our alloy's chromium content forms a protective oxide layer that seals out oxygen, while molybdenum bolsters resistance to reducing agents. We've seen it thrive in furnaces and incinerators where temps soar, maintaining integrity where others oxidize away. Stress-corrosion cracking? It's a silent killer in pressured systems with chlorides, but our wire's low carbon and titanium stabilization prevent intergranular attacks. In lab tests, it shows no cracking after over 1,000 hours in boiling magnesium chloride—impressive stats that back up real-world reliability. At DLX, we refine our manufacturing to enhance these traits, using state-of-the-art drawing and annealing processes for uniform properties along the wire's length.

Industry analysis wise, the push for eco-friendly tech is huge. With regulations cracking down on emissions, sectors like chemical and energy need materials that last in scrubbers and reactors. Hastelloy C-4 wire fits perfectly, supporting clean processes without contributing to pollution through frequent replacements. We're also seeing growth in aerospace and pharma, where purity and resistance are non-negotiable. Market reports highlight Asia-Pacific as a hot spot for demand, but DLX serves globally, ensuring our Stable Hastelloy C-4 Wire reaches where it's needed. Challenges like raw material volatility—nickel prices fluctuate—but we've secured stable supplies to keep costs down for customers.

Applications extend beyond the obvious. In oil and gas, our wire is used in downhole tools facing sour gas, resisting hydrogen sulfide-induced cracking. For renewable energy, think geothermal plants with hot, corrosive fluids—our product handles the heat and chemistry. Even in medical equipment sterilization, where high-temps and chemicals mix, it provides durable components. We at DLX encourage innovative uses, offering samples and consultations to explore new frontiers.

Comparing to market standards again, our advantage lies in customization. While others offer off-the-shelf products, we tailor diameters, coatings, and lengths to fit exact specs, reducing waste and installation time. Our R&D focuses on enhancing fatigue resistance for cyclic loading, a step ahead of generic options. Service-wise, DLX provides full traceability, certifications, and post-sale support—rare in a competitive field. This holistic approach ensures our Stable Hastelloy C-4 Wire not only meets but exceeds expectations in high-temperature oxidizing atmospheres and stress-corrosion cracking scenarios.

For more details, pls directly contact us.

About Us:

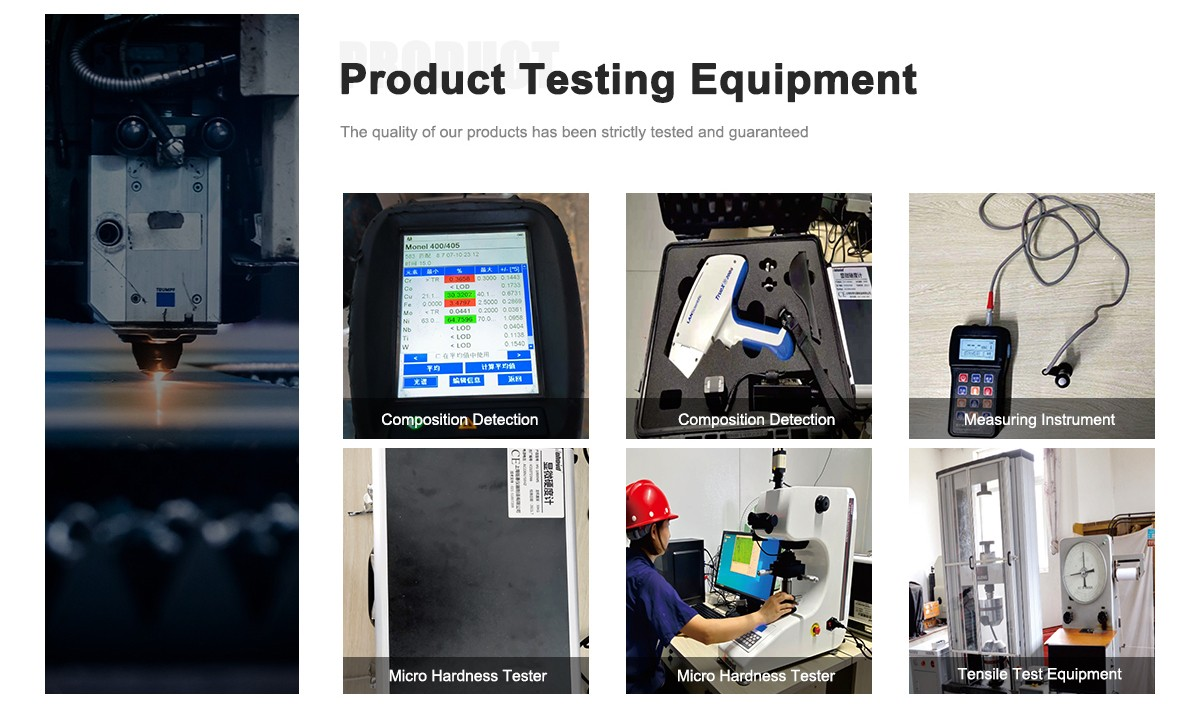

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Hastelloy C-4 alloy used in the wire?

Hastelloy C-4 consists of approximately 65% nickel, 16% chromium, 16% molybdenum, with maximum 3% iron, 2% cobalt, 1% manganese, 0.7% titanium, 0.08% silicon, 0.01% carbon, and 0.5% copper.

What are the key mechanical properties of Hastelloy C-4 wire?

It has a tensile strength of around 111 ksi at room temperature, yield strength of 60 ksi, elongation of 52%, density of 8.64 g/cm³, and maintains strength up to 1900°F with good ductility.

How does Hastelloy C-4 wire resist high-temperature oxidizing atmospheres?

Its high chromium and molybdenum content provides exceptional oxidation resistance, preventing degradation in environments up to 1900°F while maintaining structural stability.

What makes Hastelloy C-4 wire effective against stress-corrosion cracking?

The alloy's microstructural stability and resistance to chloride-induced pitting and crevice corrosion minimize cracking in aggressive chemical environments.

What are common applications for Hastelloy C-4 wire?

It's used in chemical processing, pollution control equipment, pulp and paper production, waste incineration, and marine environments where corrosion resistance is critical.

How does Hastelloy C-4 wire perform in corrosive acids?

It shows low corrosion rates (below 0.1 mm/year) in hydrochloric, sulfuric, hydrobromic, and hydrofluoric acids at various concentrations and temperatures.

What are current industry trends for alloys like Hastelloy C-4?

The superalloy market, including Hastelloy, is growing at a CAGR of 3.8%, driven by demand in chemical, oil, marine, and aerospace sectors, with projections reaching $8.5 billion by 2034.

How does Hastelloy C-4 wire compare to similar alloys in thermal stability?

It offers superior thermal stability during welding, requiring longer exposure times for grain boundary precipitation compared to other nickel-chromium-molybdenum alloys.