Durable Hastelloy B-2 UNS N10665 Wire for Chemical Processing and Pollution Control Systems

At DLX, we're constantly innovating to meet the demands of tough industrial settings, and our Durable Hastelloy B-2 UNS N10665 Wire for Chemical Processing and Pollution Control Systems exemplifies that commitment. This wire is designed to withstand the rigors of corrosive environments, ensuring your operations run smoothly without unexpected failures. We've crafted it with precision, drawing on our expertise to provide a product that's reliable, versatile, and built to last in chemical processing and pollution control applications.

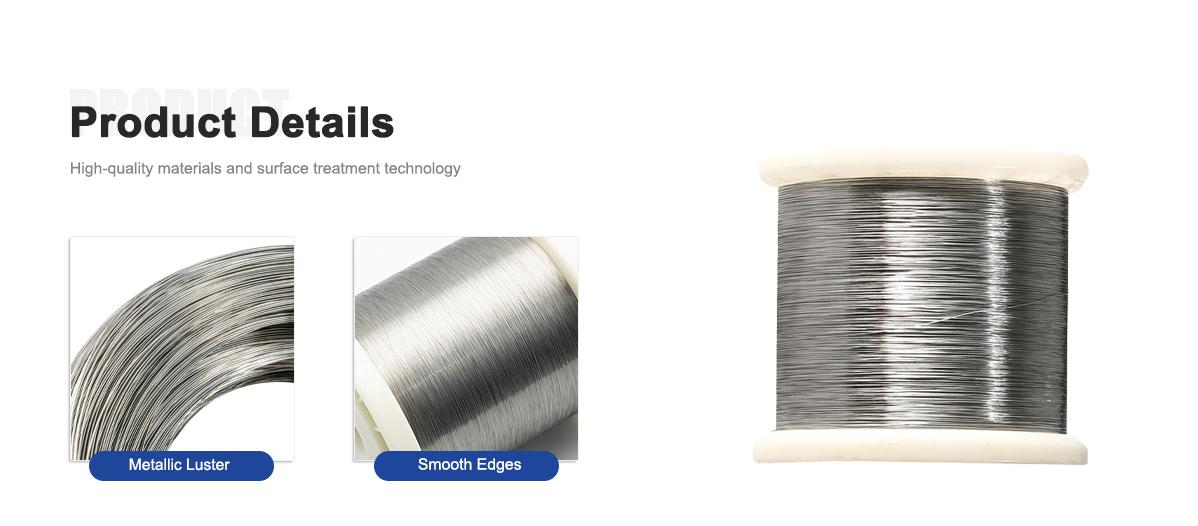

Let's kick things off with a closer look at the product itself. Our Durable Hastelloy B-2 UNS N10665 Wire is a premium nickel-molybdenum alloy, featuring a balanced composition that includes nickel at around 65-68% as the base, 28% molybdenum for that core corrosion resistance, and strict limits on impurities like iron at 2% max, chromium at 1% max, and carbon at just 0.01% max. This setup makes it incredibly resistant to reducing acids and environments where oxidants are absent, preventing issues like pitting, crevice corrosion, and stress-corrosion cracking. Mechanically, it's a powerhouse with tensile strength reaching 110 ksi, yield strength at 51 ksi, and elongation up to 60%, all while maintaining a density of 9.22 g/cm³. It performs well up to 1500°F in non-oxidizing conditions, making it perfect for heated processes. At DLX, we offer this wire in a variety of diameters and forms, from fine gauges for detailed components to heavier strands for structural elements. Its durability shines in chemical processing, where it handles harsh acids without degrading, and in pollution control systems, where it stands up to acidic gases and condensates. We've optimized it for weldability too, though we recommend controlled heat inputs to avoid any heat-affected zone sensitivities—resulting in joints that are as tough as the wire itself.

For more details, pls directly contact us.

Turning to the industry analysis, the Hastelloy alloy market is showing strong momentum as we navigate 2025. Valued at USD 1.2 billion in 2024, it's on track to hit USD 1.9 billion by 2033, with a steady CAGR of 5.5%. This growth is largely fueled by expanding needs in chemical processing and pollution control sectors, where environmental regulations are pushing for more robust, sustainable materials. We're seeing a shift toward alloys that reduce maintenance and extend equipment life, aligning with global sustainability goals to minimize waste and emissions. Nickel price fluctuations remain a challenge, but at DLX, we've mitigated this through strategic sourcing, ensuring stable pricing for our customers. Broader trends include increased adoption in emerging markets like Asia-Pacific, where chemical industries are booming, and integration with advanced technologies for smarter pollution monitoring. The market's volume is also rising, with projections for continued expansion at around 8% CAGR in related superalloy segments through 2035. As regulations tighten on emissions and waste handling, demand for durable wires like our Hastelloy B-2 UNS N10665 is surging, particularly in systems that handle reducing corrosives without frequent replacements.

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Applications for our Durable Hastelloy B-2 UNS N10665 Wire are diverse and critical in high-stakes environments. In chemical processing, it's a staple for reactors and piping dealing with hydrochloric, sulfuric, or phosphoric acids—corrosion rates stay below 0.1 mm/year even in boiling solutions, keeping production lines efficient. Pollution control systems benefit hugely; think flue gas desulfurization units or scrubbers where acidic condensates could corrode standard materials—our wire resists those attacks, extending system lifespan and reducing downtime. We've deployed it in pharmaceutical manufacturing for pure acid handling, ensuring no contamination in sensitive processes. Vacuum furnaces use it for components exposed to reducing atmospheres at high temps, while fertilizer plants rely on it for phosphoric acid environments. At DLX, we tailor the wire for specific setups, like welding fillers in tank linings or meshes in filtration systems. It's also finding traction in marine pollution control, handling saltwater-mixed acids, and even in renewable energy for biofuel processors facing organic reducers. The wire's ability to maintain integrity in non-oxidizing conditions makes it indispensable, offering peace of mind in operations where failure isn't an option.

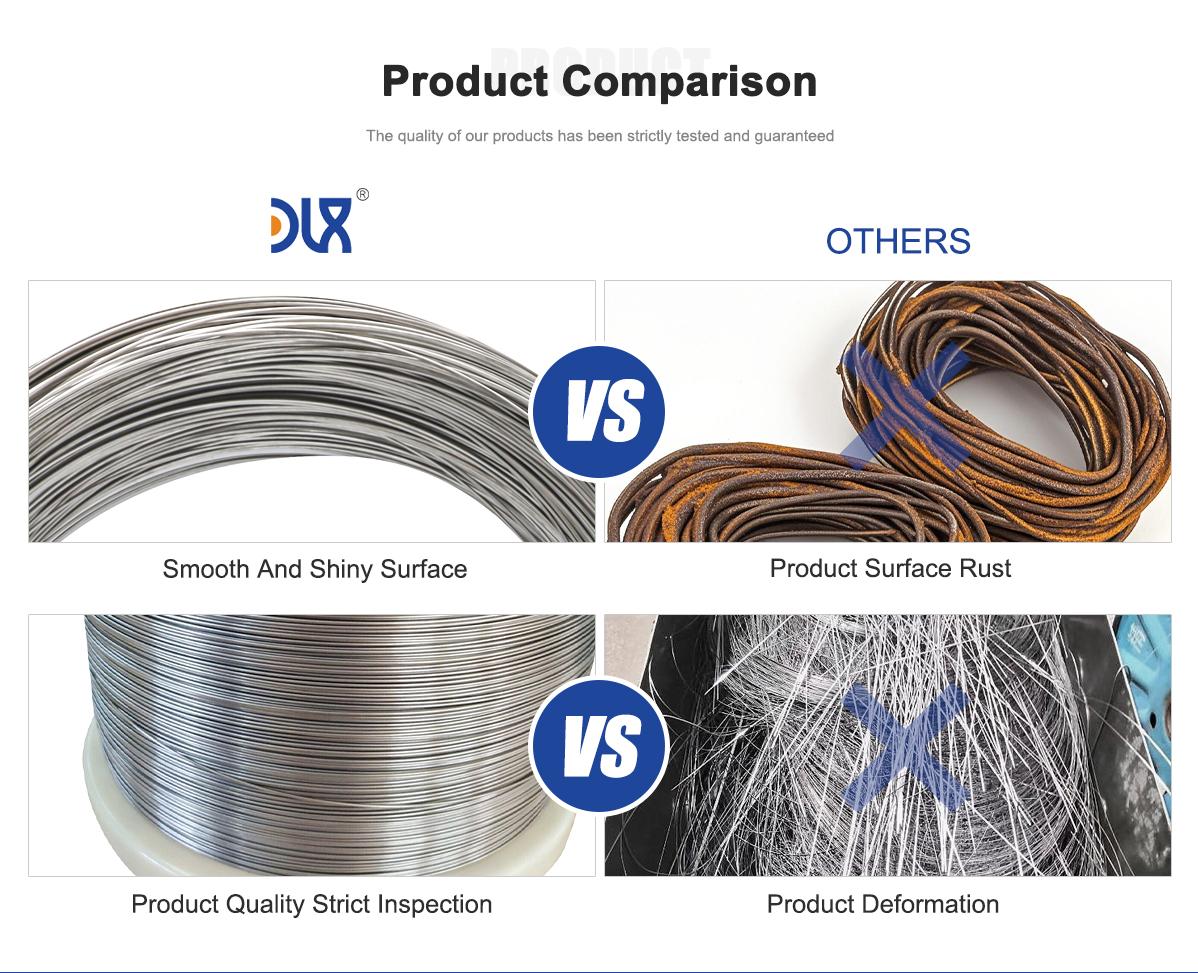

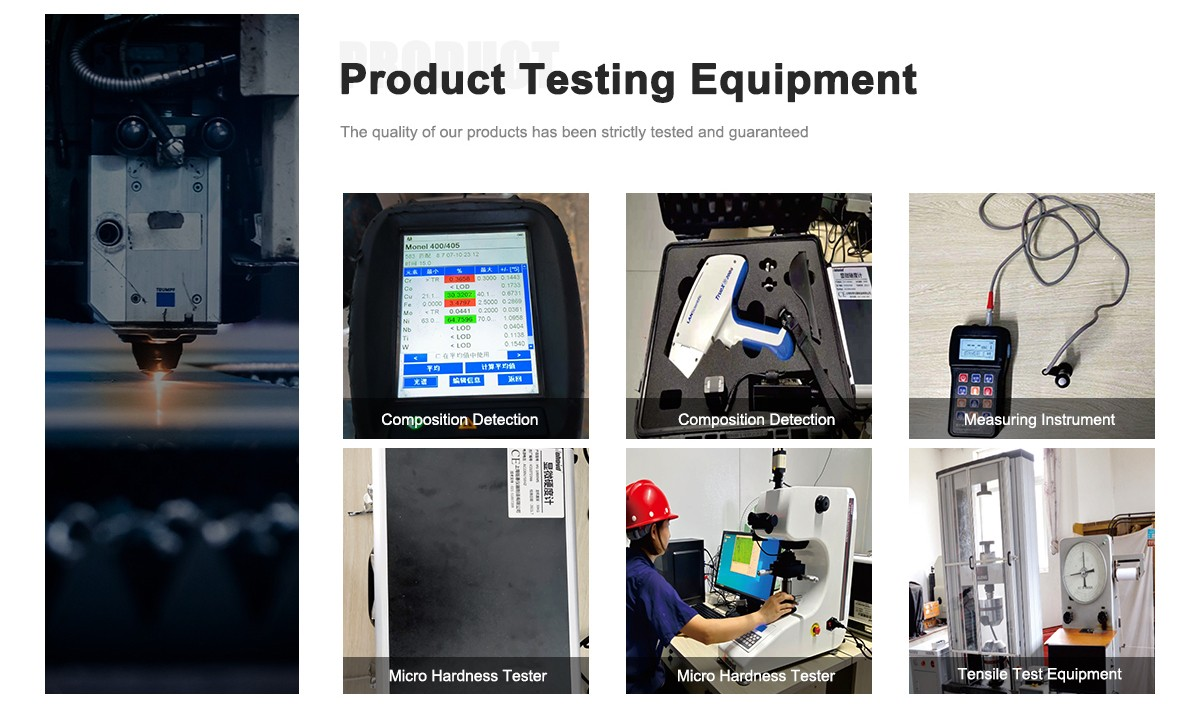

When we stack our product against offerings from other companies, the advantages of choosing DLX become crystal clear. While many alternatives struggle with consistency in reducing environments, our Hastelloy B-2 UNS N10665 wire delivers superior resistance without the pitfalls of higher-chromium alloys that falter in pure reducers. Some competitors' wires are prone to quicker sensitization during welding, but ours, with its low carbon control, holds up better, requiring careful but straightforward fabrication techniques. In chemical processing and pollution control, this means fewer field repairs and longer intervals between inspections. Mechanically, our wire's high elongation and strength provide better performance under stress, outlasting generic options in cyclic operations. What truly sets DLX apart is our end-to-end support—we customize specifications like diameter, temper, and surface treatments to match your exact needs, something not always prioritized elsewhere. Our in-house testing ensures every batch meets UNS N10665 standards, with full traceability and certifications that build confidence. Lead times? We're faster thanks to optimized production, and our pricing reflects true value through extended durability, cutting your total costs. Plus, we focus on sustainable practices in manufacturing, helping you align with eco-regs without compromising on quality. In essence, DLX offers a wire that's not just durable but a strategic asset for your chemical processing and pollution control systems.

Comparison Parameters Table

| Parameter | Hastelloy B-2 (UNS N10665) | Hastelloy B-3 | Hastelloy C-276 |

|---|---|---|---|

| Nominal Composition | Ni bal (65-68%), Mo 28%, Fe 2% max, Cr 1% max, C 0.01% max | Ni 65% min, Mo 28.5%, Cr 1.5%, Fe 1.5%, Co 3% max, C 0.01% max | Ni bal, Cr 16%, Mo 16%, W 4%, Fe 5%, C 0.01% max |

| Density (g/cm³) | 9.22 | 9.22 | 8.89 |

| Tensile Strength (ksi at RT) | 110 | 110 | 110 |

| Yield Strength (ksi at RT) | 51 | 51 | 52 |

| Elongation (%) | 40-60 | 40-60 | 60 |

| Max Operating Temp (°F) | 1500 | 1500 | 1900 |

| Corrosion Resistance | Exceptional in pure reducing acids (HCl, H2SO4); resists SCC; avoids oxidizers | Similar to B-2 with better thermal stability and intergranular resistance | Broad in reducing/oxidizing; excellent in mixed acids and wet chlorine |

| Pitting Resistance (CPT °C) | Low (reducing focused) | Low | 65 |

| Applications | Chemical processing, pollution control in reducing environments | Welded parts in reducing acids, fabrication-heavy chemical uses | Flue gas desulfurization, oil & gas, versatile corrosives |

| Weldability | Good with controlled heat to avoid HAZ issues | Superior stability; easier welding without quick precipitation | Good, minimal sensitivity, versatile |

| Key Advantage | Optimal for highly reducing chemical and pollution control systems | Enhanced fabrication over B-2 in similar environments | Versatility in mixed corrosive media |

Going deeper into the product's features, the high molybdenum in our Durable Hastelloy B-2 UNS N10665 Wire is key to its acid resistance. In pollution control, it forms a stable passive film against sulfuric condensates, preventing uniform corrosion even in humid, acidic setups. For chemical processing, tests show negligible attack in 20% hydrochloric at elevated temps, making it ideal for distillation columns. We've enhanced its durability through precise annealing, ensuring uniform properties that resist embrittlement over time. Stress-corrosion cracking is minimized, with no failures in extended exposure to chloride-tainted reducers.

Industry-wise, the emphasis on green tech is transforming how we approach materials. With stricter pollution controls globally, systems need wires like ours that support efficient scrubbing without contributing to waste. Growth in pharma and energy sectors adds to the momentum, with Hastelloy B-2 fitting perfectly for high-purity demands. At DLX, we're ahead by investing in R&D for hybrid applications, blending our wire with composites for even tougher setups.

Applications continue to evolve. In oil refining, it tackles alkylation with sulfuric catalysts, resisting degradation. Biofuel plants use it for acetic byproducts, while battery production benefits from its stability in acid electrolytes. We provide samples for testing, often leading to breakthroughs in custom uses.

In comparisons, our edge lies in reliability—while others might offer similar specs on paper, DLX's real-world performance, backed by client feedback, shows longer service in harsh conditions. We avoid the oxidation sensitivities of mixed alloys, focusing purely on reducing excellence. With expert guidance and quick adaptations, DLX minimizes your risks and maximizes uptime.

All in all, our Durable Hastelloy B-2 UNS N10665 Wire is engineered for the challenges of chemical processing and pollution control systems. At DLX, we blend expertise with innovation to deliver solutions that endure, supporting your goals in a demanding industry. As trends lean toward sustainability and efficiency, this wire positions you for success, offering unmatched durability where it matters most.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Hastelloy B-2 UNS N10665 wire?

It features nickel as the balance (approximately 65-68%), molybdenum at 28%, iron up to 2% max, chromium 1% max, cobalt 1% max, manganese 1% max, silicon 0.1% max, carbon 0.01% max, and phosphorus/sulfur 0.03% max each.

What are the mechanical properties of Hastelloy B-2 UNS N10665 wire?

It offers tensile strength of about 110 ksi, yield strength of 51 ksi, elongation between 40-60%, density of 9.22 g/cm³, and good ductility up to 1500°F with excellent weldability when controlled.

How does Hastelloy B-2 UNS N10665 wire perform in chemical processing environments?

It provides outstanding resistance to reducing acids like hydrochloric and sulfuric, with corrosion rates under 0.1 mm/year in boiling conditions, preventing pitting and stress-corrosion cracking.

What makes Hastelloy B-2 UNS N10665 wire suitable for pollution control systems?

Its high molybdenum content ensures durability in acidic gases and condensates, resisting uniform corrosion and maintaining integrity in scrubbers and flue gas desulfurization units.

What are typical applications for Hastelloy B-2 UNS N10665 wire?

It's applied in chemical reactors for acid handling, pollution control scrubbers, pharmaceutical equipment, vacuum furnaces, and piping systems exposed to reducing corrosives.

How does Hastelloy B-2 UNS N10665 wire handle high-temperature conditions?

It maintains stability up to 1500°F in non-oxidizing atmospheres, with low corrosion in hot acids such as 20% hydrochloric at 200°F, ideal for heated chemical processes.

What are current industry trends for alloys like Hastelloy B-2?

The Hastelloy alloy market, valued at USD 1.2 billion in 2024, is projected to reach USD 1.9 billion by 2033, growing at a CAGR of 5.5%, driven by demand in chemical processing and pollution control amid sustainability focuses.

Why is Hastelloy B-2 UNS N10665 wire durable for long-term use in harsh environments?

Its optimized composition minimizes sensitization and intergranular corrosion, offering extended service life in reducing media without the vulnerabilities seen in oxidizing alloys.