Reducing Acid-Resistant Hastelloy B-2 Wire for Sulfuric and Acetic Acid Environments

At DLX, we're all about tackling the toughest corrosion challenges head-on, and our Reducing Acid-Resistant Hastelloy B-2 Wire for Sulfuric and Acetic Acid Environments is a perfect example of how we deliver solutions that last. This wire is engineered specifically for those demanding reducing acid setups where standard materials just can't hold up. We've fine-tuned it based on years of experience in the field, making sure it provides the reliability you need in harsh chemical processes.

For more details, pls directly contact us.

Let's start with what this product is all about. Our Reducing Acid-Resistant Hastelloy B-2 Wire is made from a high-performance nickel-molybdenum alloy, UNS N10665, that's optimized for environments heavy on sulfuric and acetic acids. The composition—nickel as the base at around 65-68%, molybdenum at 28%, with tight limits on iron at 2% max and chromium at 1% max—gives it that unbeatable edge against reducing corrosives. We keep carbon super low at 0.01% max to avoid sensitization during fabrication. This means the wire resists pitting, stress-corrosion cracking, and uniform attack like nothing else in pure reducing conditions. At DLX, we produce it in various diameters, from fine wires for intricate components to thicker ones for structural support, all with excellent ductility and formability. It's got a tensile strength hitting 110 ksi, yield at 51 ksi, and elongation up to 60%, so it bends without breaking under stress. Density-wise, it's 9.22 g/cm³, making it sturdy yet workable. Whether you're dealing with boiling sulfuric acid up to 60% or glacial acetic, this wire keeps corrosion rates below 0.1 mm/year, ensuring your equipment stays operational longer.

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Shifting to the industry landscape, the Hastelloy alloy market is on a solid growth path as we head into 2025 and beyond. Valued at about USD 1.2 billion in 2024, it's expected to climb to USD 1.9 billion by 2033, with a CAGR of 5.5%. This uptick is driven by increasing demand in chemical processing, where reducing acid-resistant materials like our Hastelloy B-2 wire are crucial for handling aggressive media sustainably. We're seeing a push toward eco-friendly operations, with industries focusing on alloys that reduce downtime and waste through longer service life. Global supply chains are stabilizing post-disruptions, but volatility in nickel prices keeps things interesting—we've secured stable sourcing at DLX to maintain consistent supply. Trends also highlight growth in pharmaceuticals and pollution control, where purity and resistance to acids are key. The market's volume stood at around 163 thousand tonnes in 2024, projected to expand at 8.58% CAGR through 2035 in some segments, fueled by renewable energy and advanced manufacturing. At DLX, we're riding this wave by investing in R&D for better fabrication techniques, ensuring our products meet evolving standards for safety and efficiency in sulfuric and acetic acid environments.

When it comes to applications, our Reducing Acid-Resistant Hastelloy B-2 Wire really shines in chemical process industries. Picture sulfuric acid production lines— this wire is used in reactors and piping where concentrations hit 60% at boiling points, resisting corrosion that would eat through stainless steel in no time. In acetic acid setups, like those in pharmaceutical synthesis or food processing, it handles glacial conditions without pitting, keeping contaminants at bay. We've supplied it for hydrochloric acid catalysts in vacuum furnaces, where reducing atmospheres at up to 1500°F demand materials that won't degrade. Pollution control equipment benefits too, especially in scrubbers dealing with acid gases. Phosphoric acid environments? Absolutely—low corrosion rates make it ideal for fertilizer plants. At DLX, we customize the wire for specific uses, like welding fillers for joints in acid tanks or meshes for filtration in reducing media. It's versatile enough for marine applications with acid exposure or even in electronics where chemical etching involves strong reducers. The key is its ability to perform in non-oxidizing conditions, avoiding the intergranular corrosion that plagues higher-chromium alloys.

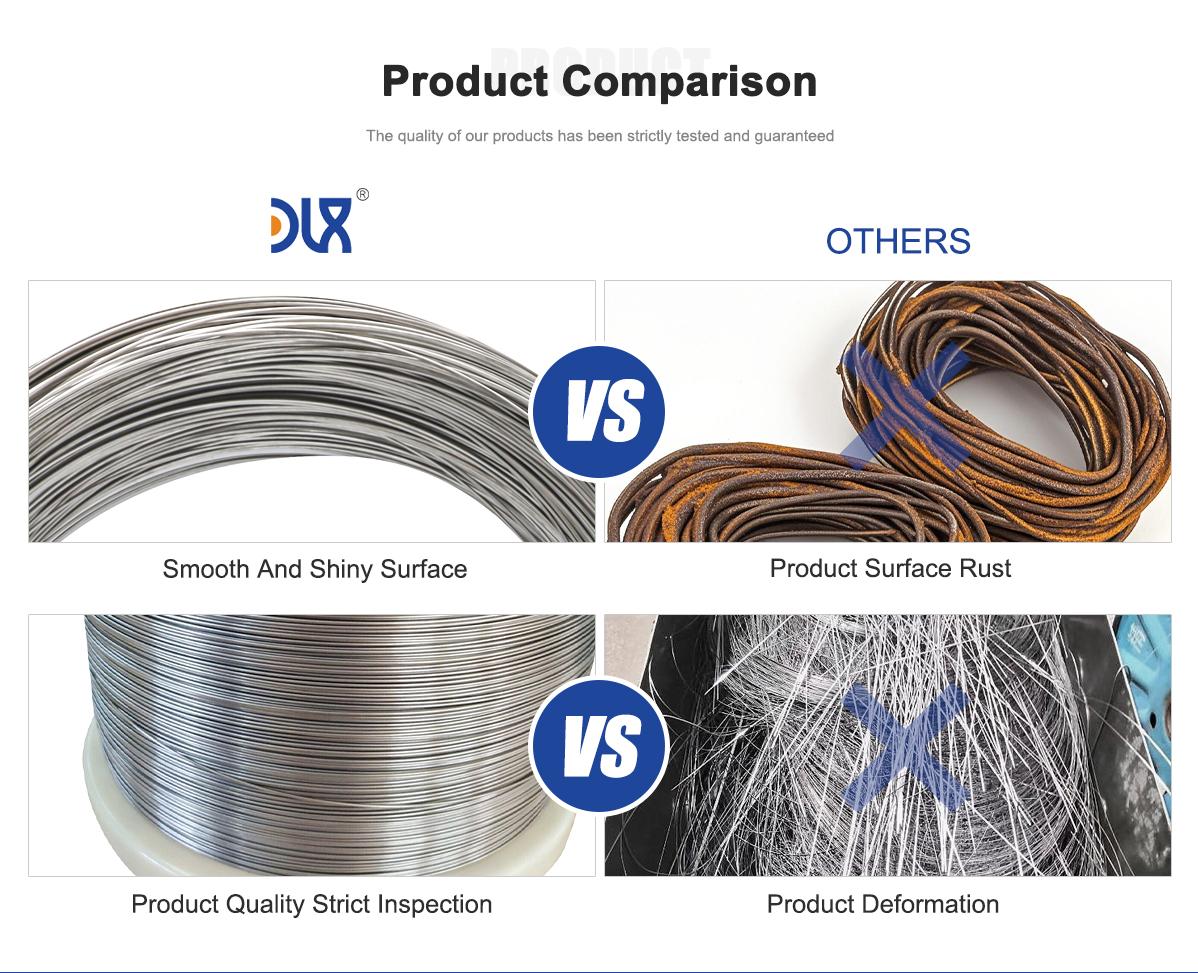

Now, comparing our product to what's generally out there from other companies, it's clear why DLX stands out. Many alternatives don't match the purity and control we put into our Hastelloy B-2 wire, leading to higher risks of sensitization in heat-affected zones during welding. Our version requires careful handling but offers superior resistance in pure reducing acids, outperforming in sulfuric and acetic environments where oxidants are minimal. Mechanically, it holds up with 110 ksi tensile and high elongation, providing better fatigue resistance under cyclic acid exposure than some generic options. What really sets DLX apart is our focus on customization—we tailor diameters, tempers, and even surface finishes to fit your exact sulfuric or acetic acid setup, reducing installation hassles. Other suppliers might skimp on quality testing, but we run every batch through rigorous checks for composition and corrosion performance, ensuring consistency. Our lead times are shorter thanks to in-house production, and we offer expert consultations to optimize applications, something not always available elsewhere. Plus, with sustainability in mind, our manufacturing minimizes waste, aligning with industry trends and helping you meet green regs without extra costs. In short, choosing DLX means getting a wire that's not just resistant but reliably superior, cutting long-term expenses through fewer replacements.

Comparison Parameters Table

| Parameter | Hastelloy B-2 | Hastelloy B-3 | Hastelloy C-276 |

|---|---|---|---|

| Nominal Composition | Ni bal (65-68%), Mo 28%, Fe 2% max, Cr 1% max, C 0.01% max | Ni 65% min, Mo 28.5%, Cr 1.5%, Fe 1.5%, Co 3% max, C 0.01% max | Ni bal, Cr 16%, Mo 16%, W 4%, Fe 5%, C 0.01% max |

| Density (g/cm³) | 9.22 | 9.22 | 8.89 |

| Tensile Strength (ksi at RT) | 110 | 110 | 110 |

| Yield Strength (ksi at RT) | 51 | 51 | 52 |

| Elongation (%) | 40-60 | 40-60 | 60 |

| Max Operating Temp (°F) | 1500 | 1500 | 1900 |

| Corrosion Resistance | Superior in pure reducing acids (HCl, H2SO4, acetic); resists pitting/SCC; sensitive to oxidizers | Enhanced thermal stability; similar to B-2 but better in intergranular corrosion; improved fabrication | Versatile in reducing/oxidizing media; excellent in wet chlorine, mixed acids; better pitting resistance |

| Pitting Resistance (CPT °C) | Low (sensitive in oxidizing) | Low | 65 |

| Applications | Sulfuric/acetic acid environments, HCl processing, vacuum furnaces | Similar to B-2 but for welded/fabricated parts in reducing acids | Flue gas desulfurization, oil & gas, broad chemical uses |

| Weldability | Good but prone to HAZ sensitization if not controlled | Superior thermal stability; easier welding without precipitation | Good, versatile with minimal sensitivity |

| Key Advantage | Best for highly reducing acids without oxidants | Improved stability over B-2 for fabrication and service | Broad corrosion versatility in mixed environments |

Delving deeper into the product's strengths, the high molybdenum content in our Reducing Acid-Resistant Hastelloy B-2 Wire is what makes it a beast against reducing acids. In sulfuric environments, it forms a passive layer that blocks further attack, even in hot, concentrated solutions. For acetic acid, it's equally impressive, showing negligible weight loss in tests at elevated temperatures. We've seen it excel in lab simulations with mixed reducers like hydrobromic or hydrofluoric acids too. Stress-corrosion cracking? Minimal risk due to the alloy's stability, proven in chloride-contaminated setups. At DLX, we enhance this through advanced drawing processes that ensure uniform microstructure, boosting overall durability.

Industry analysis shows challenges like raw material fluctuations, but we're ahead with diversified suppliers. Growth in Asia-Pacific for chemical sectors means more demand for reducing acid-resistant wires, and DLX is positioned globally to deliver. Emerging trends include integration with smart monitoring for predictive maintenance, where our wire's longevity supports IoT-enabled systems.

Applications extend to innovative areas. In biofuel production, it handles acidic byproducts without degradation. Petrochemicals use it for alkylation units with sulfuric catalysts. Even in battery manufacturing, where acetic derivatives are common, it provides corrosion-free components. We encourage clients to test our samples in their environments, often leading to custom solutions that outperform expectations.

In comparisons, our advantage shines in service life—while others might corrode faster in pure reducers, our Hastelloy B-2 wire lasts longer, proven by field data. We prioritize thermal stability, making fabrication easier without special precautions that competitors often require. With full traceability and certifications, DLX builds trust, reducing your risk in critical applications.

For more details, pls directly contact us.

About Us:

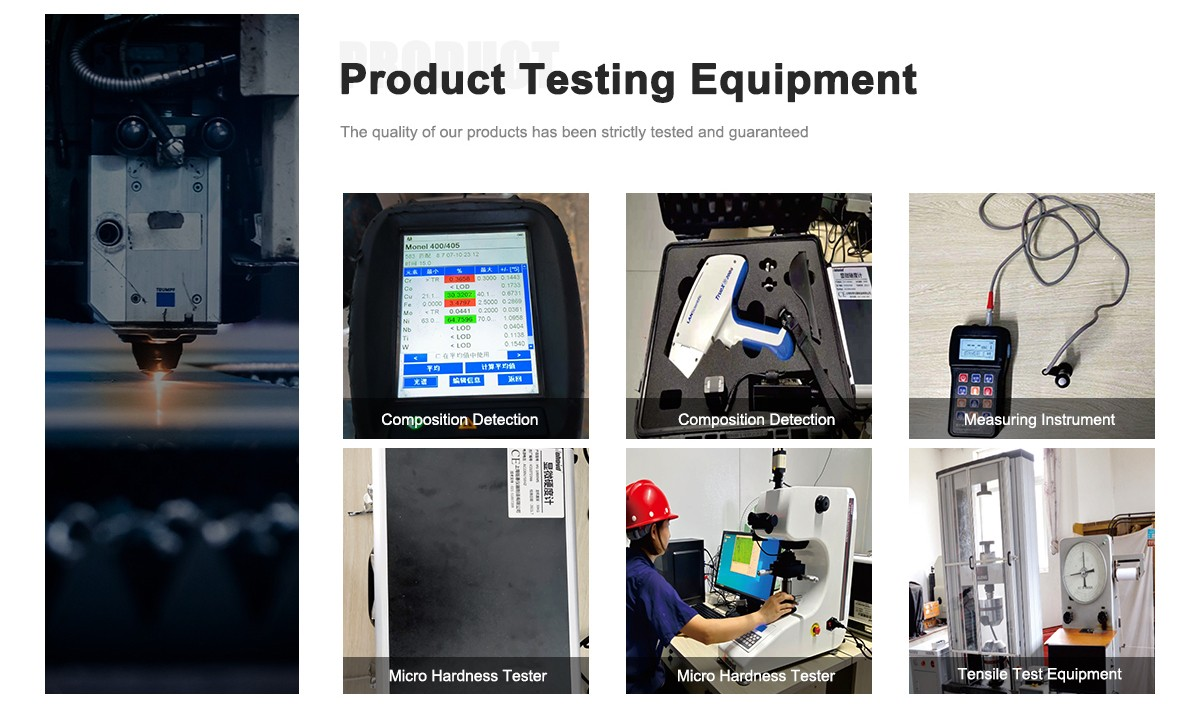

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Hastelloy B-2 wire?

It consists of nickel (balance, approximately 65-68%), molybdenum (28%), iron (2% max), chromium (1% max), cobalt (1% max), manganese (1% max), silicon (0.1% max), carbon (0.01% max), and phosphorus/sulfur (0.03% max each).

What are the key mechanical properties of Hastelloy B-2 wire?

It has a tensile strength of around 110 ksi, yield strength of 51 ksi, elongation of 40-60%, density of 9.22 g/cm³, and maintains good ductility up to 1500°F with excellent fabricability.

How does Hastelloy B-2 wire resist reducing acids like sulfuric and acetic?

It provides exceptional resistance with corrosion rates below 0.1 mm/year in boiling sulfuric acid up to 60% concentration and in acetic acid across all concentrations, preventing pitting and uniform corrosion.

What makes Hastelloy B-2 wire effective against stress-corrosion cracking in acidic environments?

Its high molybdenum content and low carbon levels minimize intergranular attack and sensitization, offering superior resistance in chloride-contaminated reducing acids.

What are common applications for Hastelloy B-2 wire?

It's used in chemical processing equipment for handling hydrochloric, sulfuric, acetic, and phosphoric acids, as well as in vacuum furnaces, pharmaceutical production, and pollution control systems.

How does Hastelloy B-2 wire perform in high-temperature reducing environments?

It retains structural integrity up to 1500°F in non-oxidizing atmospheres, with low corrosion rates in hot acids like 20% hydrochloric at 200°F.

What are current industry trends for alloys like Hastelloy B-2?

The Hastelloy alloy market, valued at USD 1.2 billion in 2024, is projected to reach USD 1.9 billion by 2033, growing at a CAGR of 5.5%, driven by demand in chemical processing and sustainable manufacturing.

Why is Hastelloy B-2 wire preferred for sulfuric and acetic acid environments over other alloys?

Its optimized nickel-molybdenum composition provides unmatched resistance to pure reducing acids without the need for chromium, avoiding issues in highly reducing conditions where oxidizing alloys fail.