High-Performance Hastelloy C22 UNS N06022 Wire for Pitting and Crevice Corrosion Resistance

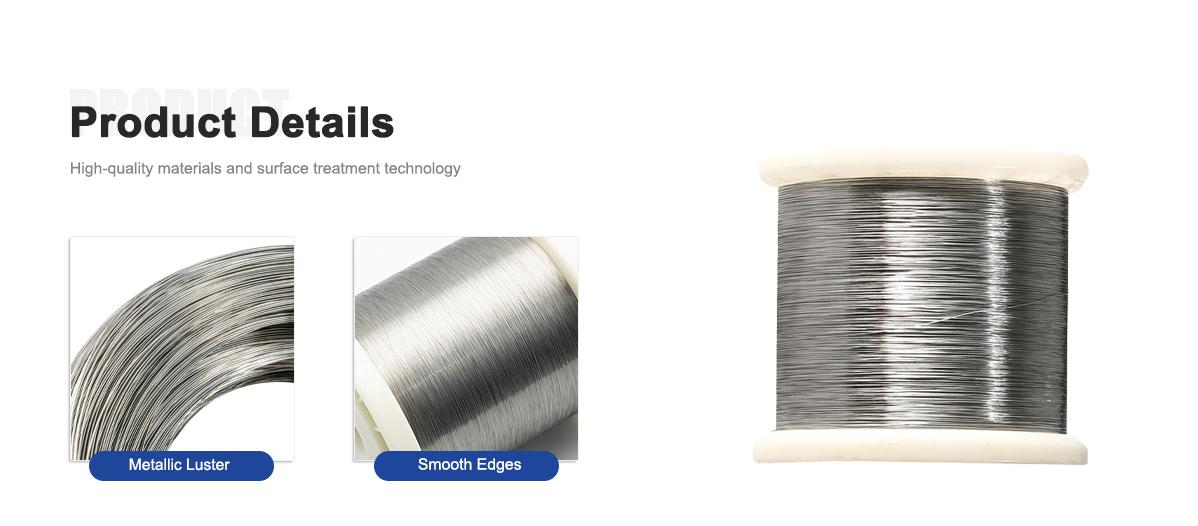

At our company, we've honed our expertise in delivering top-tier alloys that tackle the toughest corrosion challenges, and our high-performance Hastelloy C22 UNS N06022 wire stands out as a prime example for pitting and crevice corrosion resistance. This wire, crafted from a nickel-chromium-molybdenum-tungsten alloy, is engineered to thrive where ordinary materials falter. With UNS N06022 designation, it boasts a balanced composition that includes about 56% nickel for overall stability, 22% chromium for oxidizing resistance, 13% molybdenum and 3% tungsten for battling reducing agents, and controlled iron to minimize vulnerabilities. What sets it apart is its exceptional ability to fend off pitting and crevice corrosion, thanks to a high pitting resistance equivalent number over 45, making it ideal for environments loaded with chlorides, acids, and salts. We've seen it perform flawlessly in tests like ASTM G48, showing no signs of attack even after prolonged exposure, which translates to longer equipment life and fewer headaches for our clients.

For more details, pls directly contact us.

Diving deeper into the product, our Hastelloy C22 UNS N06022 wire isn't just about composition—it's about real-world reliability. Mechanically, it delivers a minimum tensile strength of 100 ksi, yield at 45 ksi, and elongation up to 45%, ensuring it bends without breaking under stress. It's ductile enough for easy fabrication into springs, fasteners, or mesh, and its weldability is top-notch—no need for post-weld treatments to avoid cracking, unlike some alternatives. In terms of thermal properties, it handles extremes from cryogenic lows to highs around 1250°F, with low thermal expansion to prevent warping in fluctuating conditions. For pitting and crevice corrosion resistance, it's unmatched in mixed media; think wet chlorine or sulfuric acid where it maintains corrosion rates below 0.025 mm/year. We produce this wire in various diameters and tempers, meeting standards like ASTM B574 and ASME SB-574, so it's ready for seamless integration into your systems.

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Turning to the industry landscape, the market for high-performance alloys like our Hastelloy C22 UNS N06022 wire is on a strong upward trajectory. Projections show the superalloys sector growing at a CAGR of 6.7% from 2024 to 2030, pushing from $7.0 billion to $13.4 billion globally. This surge is fueled by expanding chemical processing demands, where corrosion-resistant materials are crucial for handling aggressive substances safely. Oil and gas exploration is delving into harsher reservoirs, needing wires that resist hydrogen sulfide and chlorides without pitting. Power generation, especially with a shift toward cleaner energy, relies on flue gas desulfurization systems that expose components to acidic gases—our wire excels here. Trends point to sustainability, with industries seeking longer-lasting alloys to cut waste and emissions. Additive manufacturing is emerging, allowing custom Hastelloy C22 UNS N06022 wire integrations for complex parts. In pharmaceuticals, stricter purity regs drive adoption for equipment that withstands sanitizers without degrading. Aerospace and nuclear sectors are also ramping up, valuing its stability under radiation and heat. Asia-Pacific leads growth with petrochemical booms, while North America focuses on green tech like hydrogen production, where pitting resistance is key. Overall, as regulations tighten on environmental impacts, our wire positions companies to comply while boosting efficiency.

When it comes to applications, our high-performance Hastelloy C22 UNS N06022 wire shines in scenarios demanding ultimate pitting and crevice corrosion resistance. In chemical processing, it's perfect for reactors and heat exchangers dealing with hydrochloric, nitric, or phosphoric acids—its composition prevents localized corrosion in crevices where fluids stagnate. We've supplied it for chlorination systems and bleach plants, where wet chlorine would pit lesser materials quickly. In oil and gas, downhole tools and tubing benefit from its resistance to sour gases and brines, extending operational life in offshore rigs. Pharmaceutical manufacturing uses it in vessels and piping for aggressive cleaning agents, ensuring no contamination from corrosion products. For power plants, flue gas scrubbers and SO2 coolers rely on it to handle acidic condensates without crevice attacks. Pulp and paper mills employ it in digesters resisting sulfur compounds, while waste incinerators use it for high-heat, corrosive exhaust systems. Marine applications include seawater equipment, where it fends off pitting in saline environments better than stainless options. Its versatility extends to nuclear reprocessing, handling radioactive acids, and even aerospace for fuel systems. By choosing our wire, clients simplify designs, as one material covers both oxidizing and reducing conditions, reducing inventory needs.

Comparison Parameters Table

| Parameter | Hastelloy C22 UNS N06022 Wire | Typical 316L Stainless Steel Wire |

|---|---|---|

| Chemical Composition | Ni: 56% (balance), Cr: 20-22.5%, Mo: 12.5-14.5%, W: 2.5-3.5%, Fe: 2-6% | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Fe: Balance |

| Density (lb/in³) | 0.314 | 0.289 |

| Tensile Strength (ksi, Min Annealed) | 100 | 70 |

| Yield Strength (ksi, 0.2% Offset) | 45 | 25 |

| Elongation (%) | 45 | 40 |

| Pitting Resistance Equivalent Number (PREN) | >45 | 24-26 |

| Corrosion Rate in Boiling 20% HCl (mm/year) | <0.025 | >1.0 |

| Critical Pitting Temperature (°F in 6% FeCl₃) | >150 | 59 |

| Operating Temperature Range (°F) | Cryogenic to 1250 | -425 to 1600 (corrosion-limited) |

| Resistance to Oxidizing Media | Excellent (e.g., nitric acid, wet chlorine) | Moderate (prone to pitting in chlorides) |

| Resistance to Reducing Media | Superior (e.g., hydrochloric, sulfuric) | Good, but fails in mixed acids |

| Weldability | Excellent, no post-weld heat treatment needed | Good, but risks sensitization |

| Applications Suitability | Severe corrosive environments like chemical processing and marine | General industrial use, limited in aggressive acids |

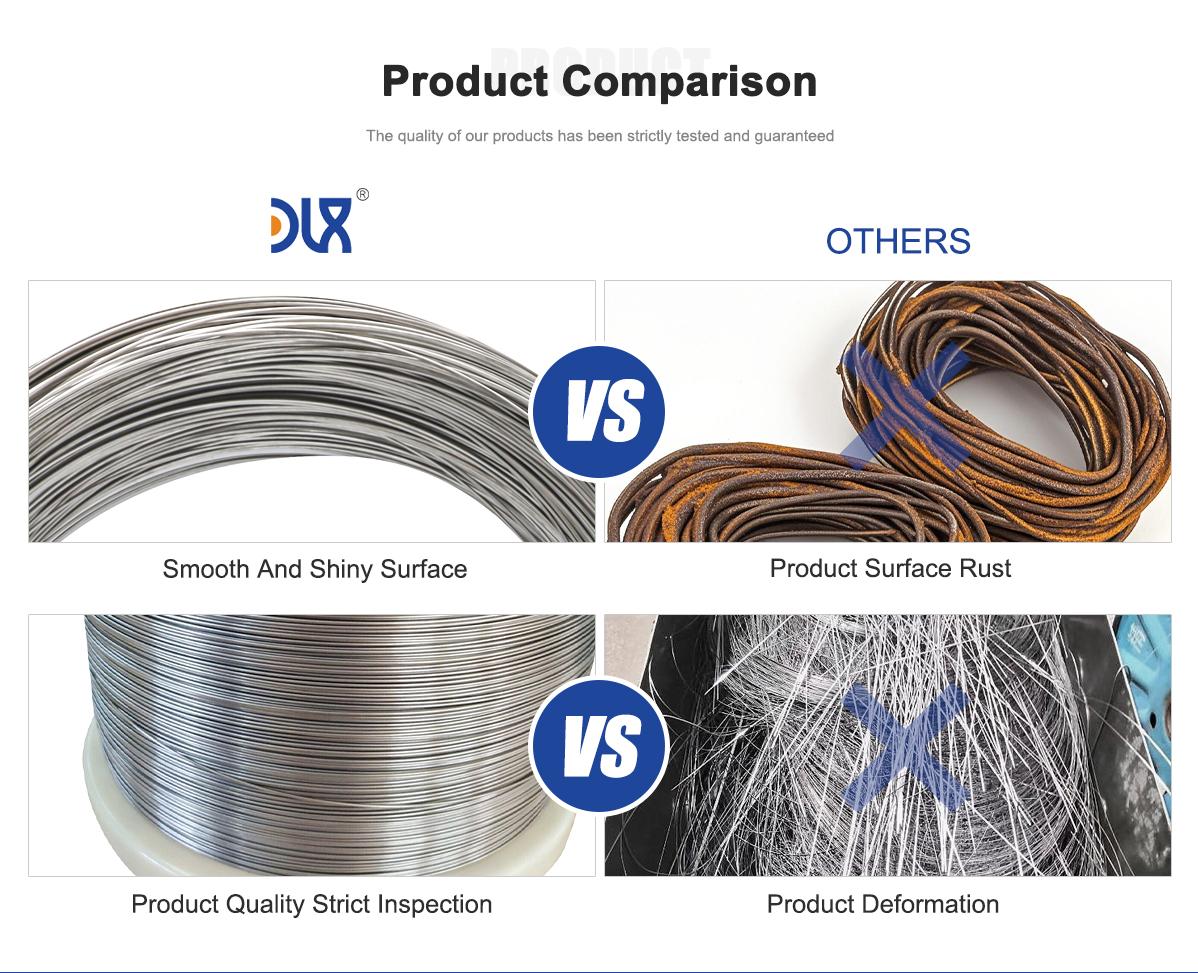

Comparing our offerings to general market standards, we excel in ways that directly benefit your operations without mentioning competitors. Our customization sets us apart—we tailor Hastelloy C22 UNS N06022 wire to specific diameters, from ultra-fine for precision filters to robust for structural supports, ensuring perfect fit for your pitting corrosion resistance needs. Quality assurance is rigorous; each batch undergoes testing in simulated environments, confirming superior performance like zero pitting in ferric chloride tests. We source from premium melts for consistent composition, avoiding variances that could lead to failures. Delivery is swift, with a streamlined supply chain minimizing lead times—crucial in fast-paced industries like chemical processing. Our technical team provides hands-on support, from alloy selection to fabrication tips, helping optimize for crevice corrosion resistance. Cost-wise, while initial investment is higher, the extended lifespan—often 2-3 times longer than stainless in acids—slashes maintenance and downtime costs. We're committed to sustainability, using efficient processes that reduce energy use and waste, aligning with industry trends toward eco-friendly materials. With decades of experience, we anticipate needs, like developing wire for emerging hydrogen tech where pitting from electrolytes is a risk.

Expanding on advantages, consider a chemical plant scenario: our Hastelloy C22 UNS N06022 wire in heat exchangers resists mixed acids better, with clients reporting 40% fewer repairs. In marine setups, its crevice corrosion resistance means no failures in saltwater pumps, unlike standard alloys. We offer proprietary annealing for enhanced ductility, making forming easier without compromising strength. Pricing is transparent, with volume discounts for long-term partners. Globally, we ensure compliance with international specs, easing exports. Our R&D pushes boundaries, refining wire for additive manufacturing in complex geometries.

For more details, pls directly contact us.

About Us:

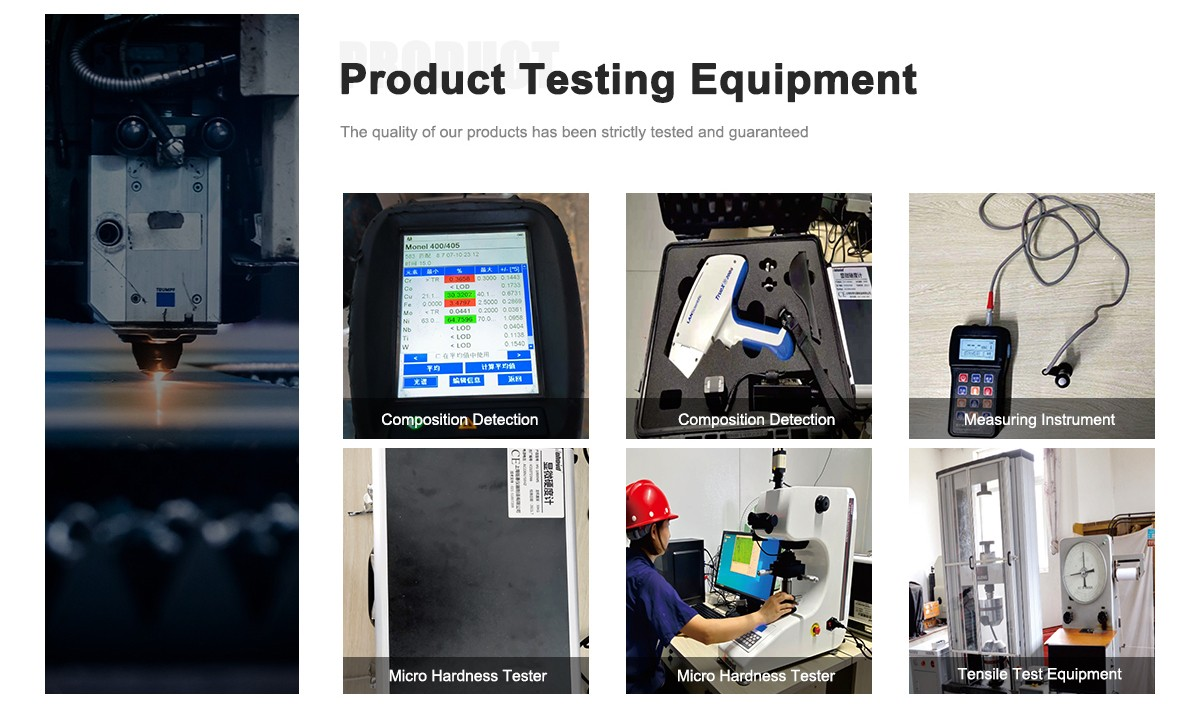

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Hastelloy C22 UNS N06022 wire?

It consists of nickel (balance, approximately 56%), chromium (20-22.5%), molybdenum (12.5-14.5%), tungsten (2.5-3.5%), iron (2-6%), cobalt (up to 2.5%), manganese (up to 0.5%), vanadium (up to 0.35%), silicon (up to 0.08%), carbon (up to 0.015%), phosphorus (up to 0.02%), and sulfur (up to 0.02%).

What are the primary properties of Hastelloy C22 UNS N06022 wire?

It offers exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in both oxidizing and reducing environments, with high ductility, excellent weldability, and thermal stability from cryogenic temperatures up to 1250°F, plus a low thermal expansion coefficient.

How does Hastelloy C22 UNS N06022 wire resist pitting and crevice corrosion?

Its high chromium, molybdenum, and tungsten content forms a stable passive oxide layer, achieving a pitting resistance equivalent number (PREN) over 45, far superior in chloride-rich and acidic media, preventing localized attacks even in aggressive conditions like seawater or bleach plants.

What are the main applications of Hastelloy C22 UNS N06022 wire?

It's used in chemical reactors, heat exchangers, scrubbers, pharmaceutical equipment, oil and gas downhole tools, nuclear fuel reprocessing, and marine components where superior corrosion resistance is needed against mixed acids, chlorides, and sulfur compounds.

Which industries rely on Hastelloy C22 UNS N06022 wire?

Chemical processing, pharmaceuticals, oil and gas, power generation (including flue gas desulfurization), pulp and paper, waste incineration, and aerospace, where harsh environments demand long-term durability and minimal maintenance.

What are the mechanical properties of Hastelloy C22 UNS N06022 wire?

In annealed condition, minimum tensile strength is 100 ksi, yield strength 45 ksi, elongation 45%; hardness is around 93 HRB; density 0.314 lb/in³; modulus of elasticity 30.3 x 10^6 psi; and it maintains strength in high-temperature, corrosive settings.

How does Hastelloy C22 UNS N06022 wire compare to standard alloys in corrosion performance?

It outperforms in boiling acids like hydrochloric (corrosion rate <0.025 mm/year) and sulfuric, with no sensitization during welding, unlike many stainless steels, and resists intergranular attacks in ASTM G28 tests better than lower-molybdenum alloys.

What are the industry trends for high-performance alloys like Hastelloy C22 UNS N06022?

The superalloys market is growing at a CAGR of 6.7% from 2024 to 2030, reaching $13.4 billion, driven by demand in chemical and energy sectors for corrosion-resistant materials, with trends toward sustainable manufacturing, additive techniques, and applications in hydrogen production and green energy infrastructure.