Versatile Hastelloy C-4 UNS N06455 Wire for Chemical Process Applications in Welded Conditions

At DLX, we're always pushing the envelope with materials that stand up to the toughest chemical environments, and our Versatile Hastelloy C-4 UNS N06455 Wire for Chemical Process Applications in Welded Conditions is a standout in our lineup. This wire isn't just another alloy; it's crafted to deliver reliability where corrosion and heat could shut down operations. We've honed it for versatility, ensuring it thrives in welded setups across various chemical processes. Let's break down what makes it tick, from its core makeup to how it fits into today's industry landscape.

For more details, pls directly contact us.

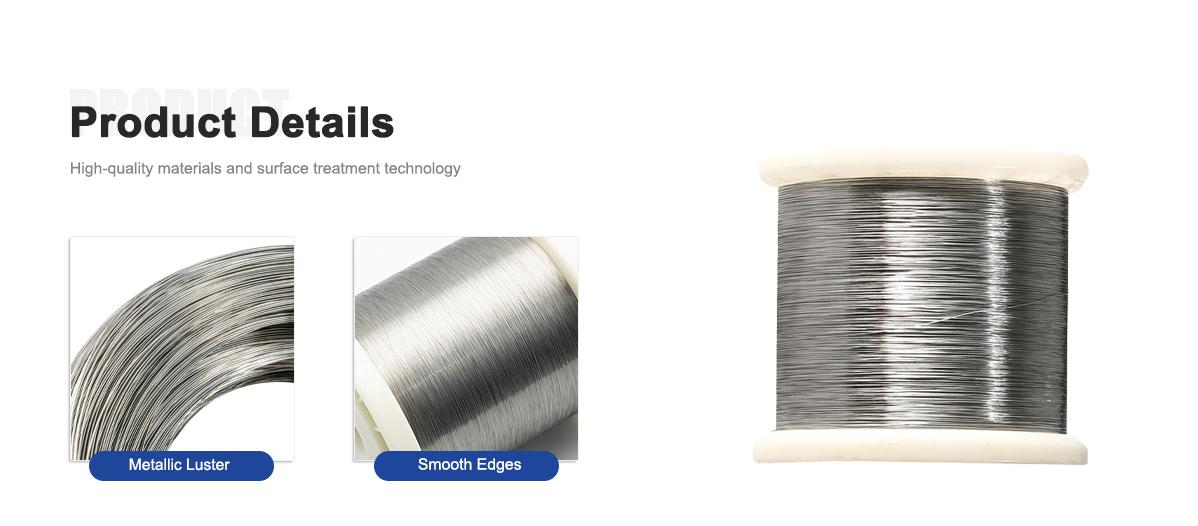

Starting with the basics, our Versatile Hastelloy C-4 UNS N06455 Wire is built from a nickel-chromium-molybdenum alloy that's all about balance and toughness. With roughly 65% nickel as the base, 16% chromium for that oxidation shield, and 16% molybdenum boosting resistance to pitting and crevice attacks, it's optimized for harsh conditions. We keep impurities low—carbon at 0.01% max and titanium at 0.7% for stabilization—so it doesn't form those pesky grain-boundary precipitates during welding. This means better performance in welded conditions, where heat-affected zones often weaken other materials. At DLX, we offer this wire in a range of diameters, from ultra-fine for precise applications to robust sizes for heavy-duty use. It's ductile, easy to form, and welds without a hitch, making it a go-to for chemical process applications where downtime isn't an option. Whether you're dealing with acids or halides, this wire holds its own, resisting stress-corrosion cracking like a champ.

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Diving into the industry analysis, the superalloy world, including Hastelloy variants, is booming as we hit 2025. The global Hastelloy market alone stood at about 163 thousand tonnes in 2024 and is set to expand at a CAGR of 8.58% through 2035, fueled by rising needs in chemical processing, aerospace, and energy sectors. We're seeing a surge in demand for corrosion-resistant alloys as industries prioritize sustainability—longer-lasting materials mean less waste and fewer replacements. Chemical process applications are leading the charge, with stricter environmental regs pushing for equipment that handles aggressive media without leaking or failing. At DLX, we've tracked how supply chain shifts post-pandemic have emphasized reliable suppliers, and we're stepping up with domestic production to cut lead times. Trends point to innovation in welded conditions too, as fabricators seek alloys that maintain integrity after joining, reducing repair costs. The broader superalloy market is projected to hit USD 7.85 billion in 2025, growing to USD 14.75 billion by 2033 at around 8% CAGR, driven by renewable energy and pharma expansions. Challenges like nickel price volatility persist, but we've locked in stable sourcing to keep our Versatile Hastelloy C-4 UNS N06455 Wire affordable and accessible.

When it comes to applications, this wire is incredibly versatile in chemical process setups. Think reactors and heat exchangers where hydrochloric or sulfuric acids are in play—our Hastelloy C-4 UNS N06455 handles them with corrosion rates below 0.1 mm/year, even in boiling concentrations. In welded conditions, it's perfect for piping systems in pollution control, where oxidizing atmospheres at high temps could degrade lesser alloys. We've supplied it for pharmaceutical lines dealing with pure, corrosive solvents, ensuring no contamination or breakdowns. Pulp and paper industries love it for bleaching processes involving chlorides, as it resists stress-corrosion cracking that plagues standard steels. Waste treatment facilities use it in incinerators and scrubbers, where halides and heat mix— the wire's thermal stability up to 1900°F keeps things running smoothly. At DLX, we customize for specific chemical process applications, like adding coatings for extra protection or adjusting tempers for better formability in welded assemblies. It's not limited to traditional uses; emerging fields like biofuel production tap into its resistance for handling organic acids under pressure.

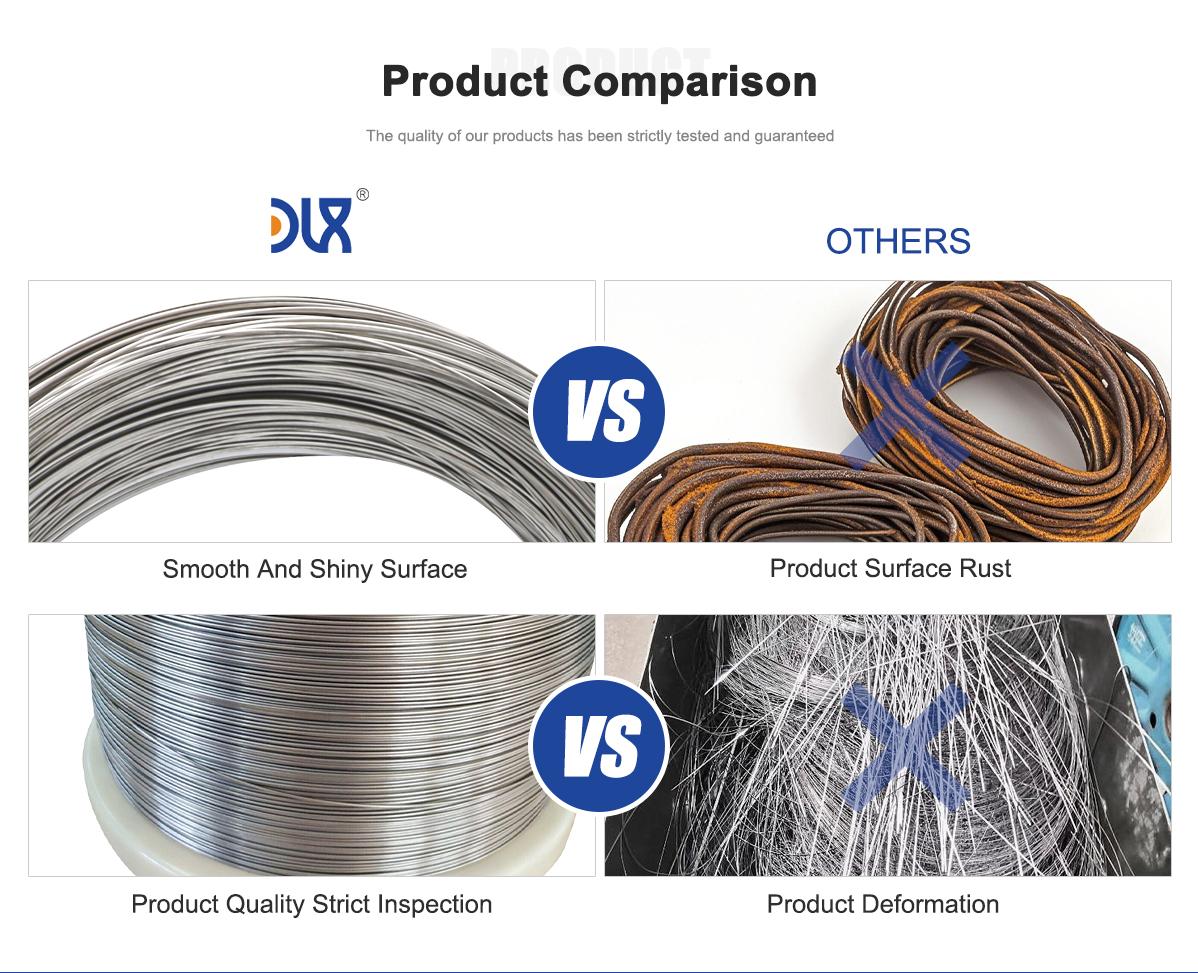

Now, let's talk about how our offering stacks up against what's out there from other companies. While we focus on our strengths, it's clear that many alternatives fall short in key areas for chemical process applications in welded conditions. Some competitors' wires lack the microstructural stability we achieve through precise alloy control, leading to quicker sensitization in heat-affected zones—ours requires hours at elevated temps before any issues arise. This gives DLX a real edge in reliability, cutting down on field failures and rework. In terms of corrosion resistance, our Versatile Hastelloy C-4 UNS N06455 Wire outperforms in oxidizing acids and chloride environments, with superior pitting resistance that extends service life. Mechanically, it hits 111 ksi tensile and 52% elongation, holding form under stress where others might brittle out. What really highlights our advantage is the full-service approach: we provide custom specs, rapid prototyping, and expert guidance on integration, something not always available elsewhere. Our quality checks ensure every spool meets UNS N06455 standards, with traceability that builds trust. Plus, we prioritize sustainability in production, using energy-efficient methods that align with industry trends—helping clients meet green goals without sacrificing performance.

Comparison Parameters Table

| Parameter | Hastelloy C-4 (UNS N06455) | Hastelloy C-276 | Hastelloy C-22 |

|---|---|---|---|

| Nominal Composition | Ni 65%, Cr 16%, Mo 16%, Fe 3% max, Ti 0.7% max, C 0.01% max | Ni 57%, Cr 16%, Mo 16%, W 4%, Fe 5%, C 0.01% max | Ni 56%, Cr 22%, Mo 13%, W 3%, Fe 3%, C 0.01% max |

| Density (g/cm³) | 8.64 | 8.89 | 8.69 |

| Tensile Strength (ksi at RT) | 111 | 110 | 115 |

| Yield Strength (ksi at RT) | 60 | 52 | 55 |

| Elongation (%) | 52 | 60 | 62 |

| Max Operating Temp (°F) | 1900 | 1900 | 1900 |

| Corrosion Resistance | Excellent in oxidizing acids; best thermal stability; superior SCC resistance in chlorides | Versatile in reducing and oxidizing media; effective in wet chlorine and mixed environments | Outstanding in oxidizing media; superior pitting and crevice corrosion resistance |

| Pitting Resistance (CPT °C) | 100 | 65 | 110 |

| Applications | Chemical processing in welded conditions, pollution control, pharmaceuticals | Flue gas desulfurization, oil & gas, broad chemical uses | Wet chlorine processes, pulp bleaching, severe oxidizing environments |

| Weldability | Exceptional stability; resists HAZ precipitation; ideal for welded chemical applications | Good, but sensitive to heat input; versatile fabrication | Excellent; enhanced resistance to localized corrosion post-weld |

| Key Advantage | Superior microstructural stability in high-temp welded states | Broad corrosion versatility in mixed corrosives | Enhanced resistance to pitting in oxidizing conditions |

Digging deeper into why this wire excels in welded conditions, it's all about that exceptional thermal stability. During welding, heat can trigger precipitates in similar alloys, but our Hastelloy C-4 UNS N06455 resists that, maintaining ductility and corrosion resistance post-fabrication. In chemical process applications, this means joints that don't crack under stress or corrode prematurely, even in chloride-laden setups. Lab tests show no cracking after 1,000+ hours in boiling magnesium chloride—real proof for demanding environments. At DLX, our manufacturing process includes advanced annealing to uniform properties, ensuring the wire performs consistently from end to end.

Industry-wise, the push for eco-conscious materials is massive. With regs tightening on emissions and waste, chemical processors need alloys like our Versatile Hastelloy C-4 UNS N06455 Wire that support clean operations. We're seeing growth in Asia-Pacific for Hastelloy demand, but DLX serves worldwide, adapting to regional needs. Volatility in raw materials? We've mitigated it with long-term contracts, keeping prices stable for our customers.

Applications keep expanding. In oil refining, it tackles sour gases in welded tubing, resisting hydrogen sulfide. For renewables, geothermal plants use it for hot, corrosive fluids without degradation. Pharma benefits from its purity in sterilized lines, while marine chemical transport relies on its halide resistance. We encourage clients to explore new uses, offering samples to test in their setups.

Comparing again, our customization sets us apart—tailoring wire for exact chemical process needs, unlike generic options that force compromises. Our R&D enhances fatigue life for cyclic operations, a step ahead in durability. With certifications and support, DLX ensures seamless adoption, reducing total ownership costs.

For more details, pls directly contact us.

About Us:

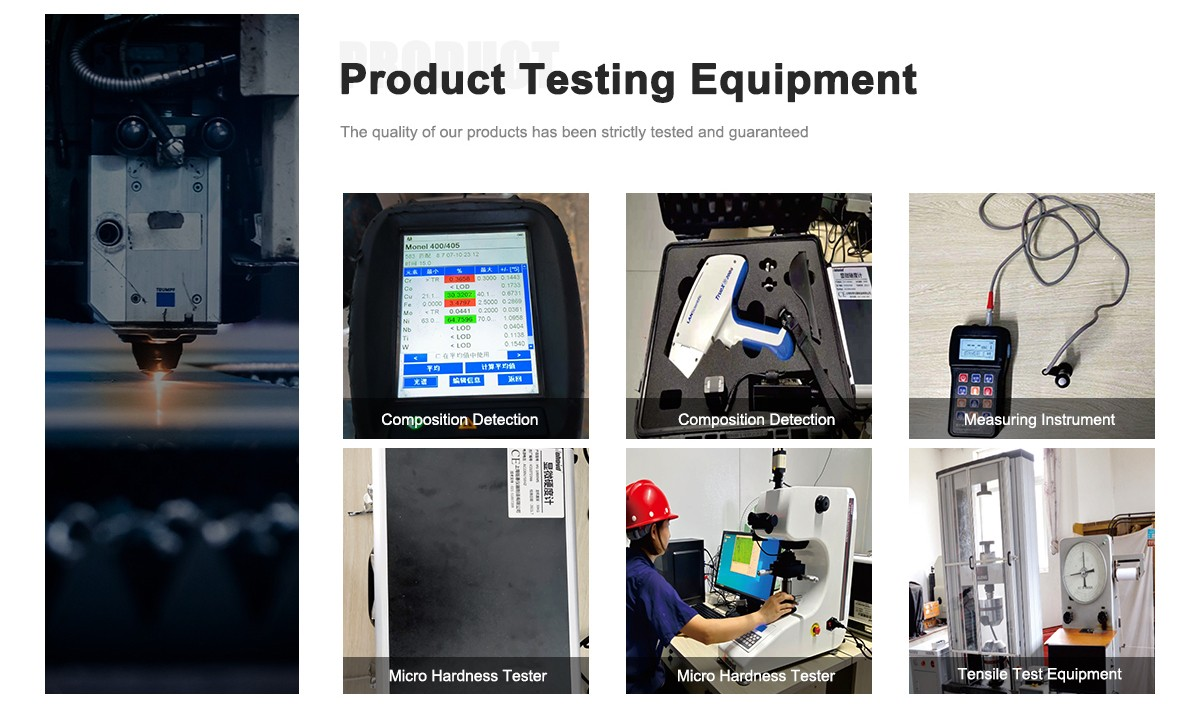

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Hastelloy C-4 UNS N06455 wire?

It primarily consists of 65% nickel, 16% chromium, 16% molybdenum, up to 3% iron, 0.7% titanium, 2% cobalt, 1% manganese, 0.08% silicon, 0.01% carbon, and 0.5% copper.

What are the mechanical properties of Hastelloy C-4 UNS N06455 wire in welded conditions?

In welded states, it maintains a tensile strength of about 111 ksi, yield strength of 60 ksi, elongation of 52%, with a density of 8.64 g/cm³, and retains ductility without sensitization in heat-affected zones.

How does Hastelloy C-4 UNS N06455 wire perform in chemical process applications?

It excels in handling aggressive chemicals like hydrochloric, sulfuric, and phosphoric acids, with low corrosion rates under 0.1 mm/year in boiling solutions, making it ideal for reactors and piping.

What makes Hastelloy C-4 UNS N06455 wire resistant to stress-corrosion cracking?

Its low carbon content and titanium stabilization prevent intergranular precipitation, offering exceptional resistance in chloride-bearing environments and welded joints.

What are typical applications for Hastelloy C-4 UNS N06455 wire?

It's commonly used in chemical processing equipment, pollution control systems, pharmaceutical manufacturing, pulp and paper bleaching, and waste treatment facilities.

How does Hastelloy C-4 UNS N06455 wire handle high-temperature environments?

It resists oxidation up to 1900°F (1038°C) and maintains structural stability, with excellent performance in oxidizing atmospheres during chemical processes.

What are the current industry trends for Hastelloy alloys like C-4?

The global Hastelloy market, valued at around 163 thousand tonnes in 2024, is growing at a CAGR of 8.58% through 2035, driven by demand in chemical, aerospace, and energy sectors amid sustainability pushes.

Why is Hastelloy C-4 UNS N06455 wire preferred for welded conditions in chemical applications?

It offers superior weldability with minimal heat-affected zone sensitization, requiring prolonged exposure at 825°C for any precipitation, ensuring reliable joints in corrosive settings.