Hastelloy C276 Wire for Chemical Processing Reactor Springs

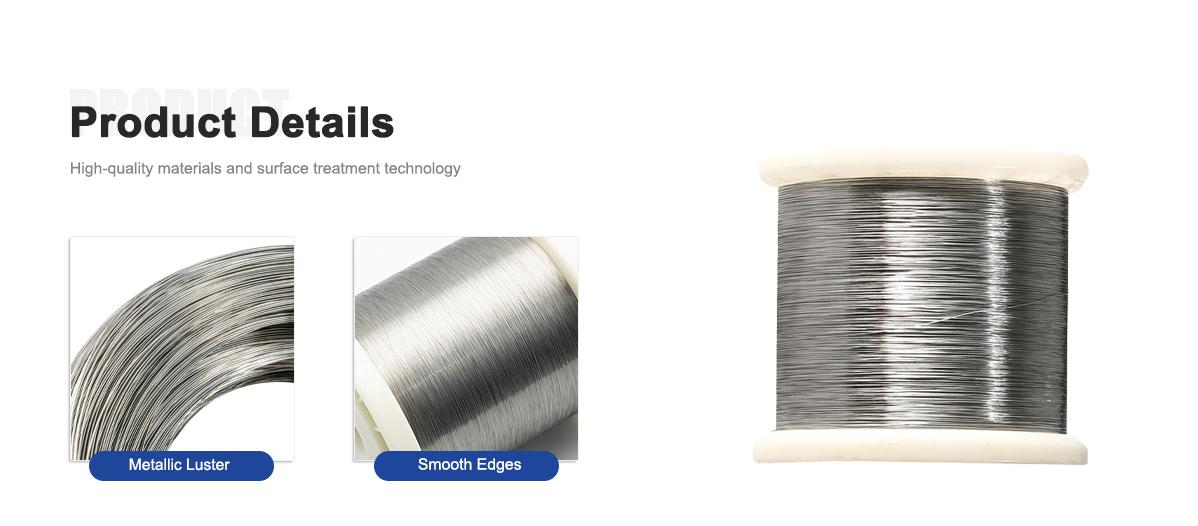

Our Hastelloy C276 wire is a total powerhouse for chemical processing reactor springs, built to handle the nastiest corrosive environments without breaking a sweat. This nickel-molybdenum-chromium alloy, with about 57% nickel, 16% molybdenum, 16% chromium, plus a touch of tungsten and iron, is our go-to for applications where corrosion resistance and strength are critical. Whether it’s springs, valve components, or mesh screens in chemical reactors, this wire keeps your systems running smoothly.

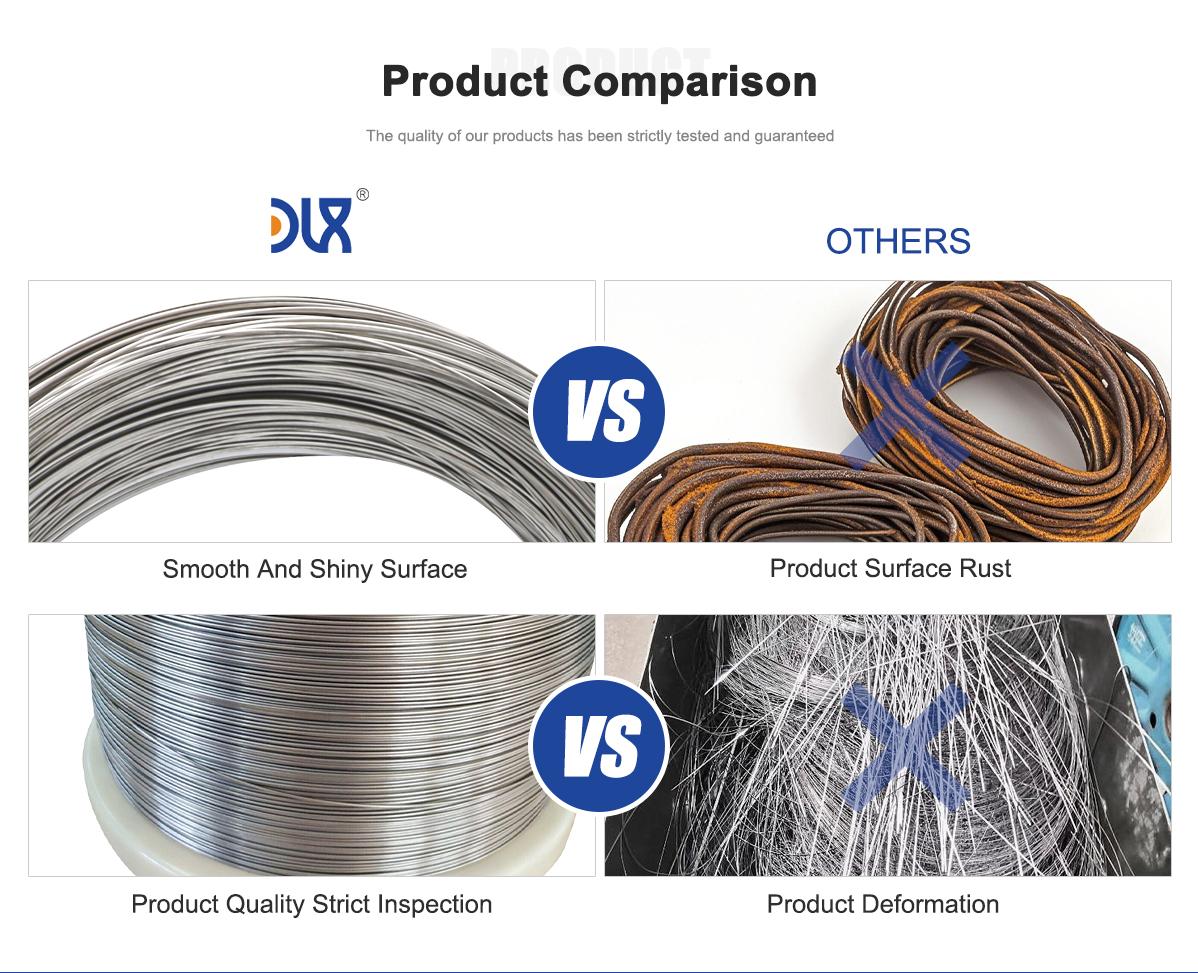

What makes Hastelloy C276 wire stand out is its incredible ability to resist corrosion from strong acids like sulfuric, hydrochloric, and nitric, as well as alkalis and chlorides. It’s perfect for reactor springs in chemical processing, where equipment needs to withstand brutal conditions to keep operations safe and efficient. This wire fights off pitting, crevice corrosion, and stress corrosion cracking, ensuring your springs stay reliable with minimal maintenance.

This wire’s versatility is a big win. It’s stable up to 1093°C, which is awesome for reactor springs in high-heat chemical environments, like those in petrochemical or pharmaceutical plants. Its low electrical conductivity (~1.5% IACS) is great for applications where electrical isolation matters, and its high strength ensures it holds up under mechanical stress. From fertilizer production to acid manufacturing, Hastelloy C276 delivers.

Comparison Parameters Table

Parameter | Hastelloy C276 Wire | Hastelloy C22 Wire | Stainless Steel 316 Wire | Monel 400 Wire |

|---|---|---|---|---|

Corrosion Resistance | Excellent (acids, chlorides, seawater) | Excellent, slightly better in oxidizing acids | Good, weaker in chlorides | Excellent, strong in seawater/acids |

Electrical Conductivity | Low (~1.5% IACS) | Low (~1.5% IACS) | Low (~2% IACS) | Moderate (~3-4% IACS) |

Thermal Stability | High (up to 1093°C) | High (up to 1038°C) | High (up to 870°C) | High (up to 550°C) |

Mechanical Strength | High, good ductility | High, slightly less ductile | Very high, less ductile | Good, high ductility |

Formability | Moderate, requires special handling | Moderate, requires special handling | Moderate, harder to form | Excellent, easy to shape and weave |

Cost | High, due to alloy complexity | High, similar to C276 | Moderate, lower than Hastelloy | High, lower than C276 |

Typical Applications | Reactor springs, valve components | Chemical linings, scrubber mesh | Marine fittings, chemical components | Marine connectors, desalination mesh |

Durability | Long lifespan, excellent in harsh conditions | Long, slightly less in pitting scenarios | Long, varies in acidic environments | Very long, slightly less in acids |

We love how adaptable this wire is, even with its tough composition. You can form, coil, or weld it into whatever your reactor spring design needs—think precision springs or durable valve components. Need a specific diameter, strength, or finish? We can tailor it to fit your specs, ensuring smooth fabrication and keeping your project on track.

The chemical processing industry’s all about materials that are durable, efficient, and sustainable, and Hastelloy C276 wire checks every box. It’s recyclable, which is great for eco-friendly projects, and its long lifespan means less waste from replacements. With global demand for specialty chemicals, green fuels, and pharmaceuticals growing, Hastelloy C276’s corrosion resistance is more critical than ever. Its low maintenance aligns with the trend toward cost-effective, sustainable operations.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Our Hastelloy C276 wire sets the standard because we’re all about quality, customization, and customer success. We offer a wide range of diameters, strengths, and finishes, with fast delivery for both small and large orders. Our team dives into your project, optimizing the wire for your reactor springs to ensure maximum corrosion resistance and performance. We keep pricing competitive, especially for bulk orders, without skimping on quality. Our sustainable production process uses recyclable materials, aligning with green industry trends. Plus, our hands-on support means you’re always covered—whether it’s technical guidance or a custom solution, we make it happen.

Compared to other materials, our Hastelloy C276 wire is a clear winner. Hastelloy C22 is great for oxidizing acids but slightly less effective against pitting and stress corrosion. Stainless steel 316 is tough but struggles with chlorides and strong acids, unlike C276. Monel 400 is corrosion-resistant but lacks C276’s strength and high-temperature stability. Our wire is the go-to for chemical processing reactor springs.

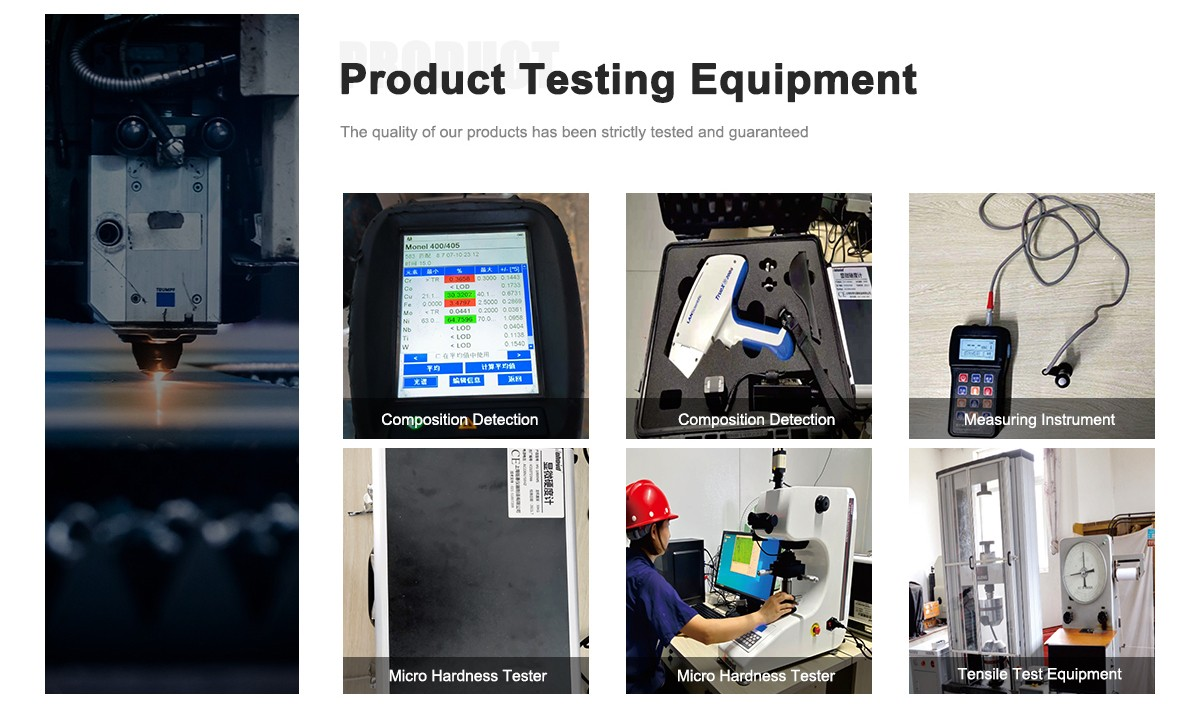

We craft our Hastelloy C276 wire to meet strict standards like ISO 9001, ensuring quality you can trust every time. Whether you’re building springs for petrochemical reactors or valve components for pharmaceutical systems, this wire’s ready to perform. Got a unique spec in mind? Let us know, and we’ll make it happen.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Hastelloy C276 wire made of?

It’s a nickel-molybdenum-chromium alloy with about 57% nickel, 16% molybdenum, 16% chromium, plus tungsten and iron for corrosion resistance and strength.What are the main uses for Hastelloy C276 wire in chemical processing?

It’s used for reactor springs, valve components, and mesh screens in chemical reactors handling corrosive substances.How does Hastelloy C276 wire perform in chemical environments?

It’s a champ, resisting corrosion from strong acids like sulfuric, hydrochloric, and nitric, plus alkalis and chlorides.Can Hastelloy C276 wire handle high temperatures?

Yep, it’s stable up to 1093°C, perfect for reactor springs in high-heat chemical processing conditions.Is Hastelloy C276 wire cost-effective?

It’s pricier than stainless steel, but its durability and low maintenance in harsh environments make it a smart choice.How does Hastelloy C276 wire compare to Hastelloy C22 wire?

C276 offers superior resistance to pitting and stress corrosion cracking, while C22 is slightly better in oxidizing acids.Can Hastelloy C276 wire be customized?

Totally! We can adjust diameter, strength, or finish to meet your specific reactor spring needs.Is Hastelloy C276 wire environmentally friendly?

It’s recyclable, supporting green practices, and its long lifespan reduces waste from replacements.