Durable Monel 400 Alloy Tubing for Aerospace and Oil & Gas Environments

At our company, we know that in the world of high-performance materials, finding the right tubing for tough environments like aerospace and oil and gas can make all the difference. That's why we're proud to offer our durable Monel 400 alloy tubing, designed specifically to handle the harshest conditions without skipping a beat. Monel 400 tubing isn't just another product on the shelf—it's a reliable solution that combines strength, corrosion resistance, and versatility to keep your operations running smoothly. Whether you're dealing with extreme pressures in deep-sea drilling or high-altitude stresses in aircraft systems, our Monel 400 alloy tubing stands out as a go-to choice for engineers and project managers who demand the best.

For more details, pls directly contact us.

Let's dive into what makes our durable Monel 400 alloy tubing so special. Starting with the basics, Monel 400 is a nickel-copper alloy that's been around for decades, but it keeps proving its worth in modern applications. Composed primarily of about 63% nickel and 28-34% copper, with traces of iron, manganese, and other elements, this alloy gets its superpowers from a solid-solution structure that enhances its mechanical properties. What does that mean in plain terms? It means our Monel 400 tubing is tough—really tough. It boasts a tensile strength ranging from 70 to 85 ksi, yield strength up to 50 ksi, and excellent ductility that prevents brittle failures even at subzero temperatures down to -200°F. And unlike some materials that weaken under heat, our tubing holds up well up to 1000°F, making it perfect for the fluctuating temperatures in oil and gas extraction or aerospace propulsion systems.

Parameter:

Item | Ni | Cu | Fe | Mn | C | Si | S |

Monel 400 | ≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Ni | Cu | Al | Ti | Fe | Mn | S | C | Si |

Monel K500 | ≥63 | 27-33 | 2.3-3.15 | 0.35-0.85 | ≤2 | ≤1.5 | ≤0.01 | ≤0.25 | ≤0.5 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation |

Monel K500 | 8.05 g/cm3 | 1288-1343℃ | 1100 | 790 | 20% |

Monel 400 | Bar / Rod | Forging | Pipe | Sheet / Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

Monel K500 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B864 | AMS4676 | ASTM B865 | ASTM B564 | ErNiCu-7 |

For more details, pls directly contact us.

But strength is only part of the story. The real star feature of our durable Monel 400 alloy tubing is its unbeatable corrosion resistance. In environments where saltwater, acids, or alkalis would eat away at lesser metals, Monel 400 tubing thrives. For instance, in seawater, it has a corrosion rate that's practically negligible, resisting pitting, crevice corrosion, and stress corrosion cracking. This is crucial for oil and gas setups, where exposure to sour gases like hydrogen sulfide can spell disaster for standard piping. Our tubing also shines in chemical processing, handling hydrofluoric acid, sulfuric acid, and even alkaline solutions without breaking a sweat. We've seen it outperform expectations in real-world scenarios, like offshore platforms where biofouling and erosion are constant threats. If you're searching for Monel 400 tubing for aerospace applications, you'll appreciate how it withstands de-icing fluids and atmospheric corrosion, ensuring longevity in aircraft fuel lines and hydraulic tubing.

Now, shifting gears to industry analysis, the landscape for materials like our durable Monel 400 alloy tubing is evolving fast. The global nickel alloys market is projected to grow steadily, driven by expanding oil and gas exploration, especially in deepwater and unconventional reserves. With energy demands rising and a push toward sustainable practices, there's a surge in demand for materials that reduce maintenance costs and extend equipment life—exactly what Monel 400 tubing delivers. In aerospace, trends point to lighter, more efficient designs, but without sacrificing durability. As electric vertical takeoff and landing (eVTOL) vehicles and hypersonic tech emerge, the need for corrosion-resistant tubing that can handle extreme conditions is skyrocketing. We've noticed a shift toward eco-friendly operations too; our Monel 400 alloy tubing supports this by minimizing leaks and failures that could lead to environmental hazards. On the oil and gas side, the industry is grappling with harsher environments due to climate change and resource scarcity, making reliable tubing a must-have. Trends like digital twinning and predictive maintenance are also influencing choices, as companies seek materials that integrate well with smart monitoring systems. Overall, the market for durable alloy tubing like ours is booming, with forecasts showing compound annual growth rates around 5-7% through the next decade, fueled by regions like the Middle East, North America, and Asia-Pacific.

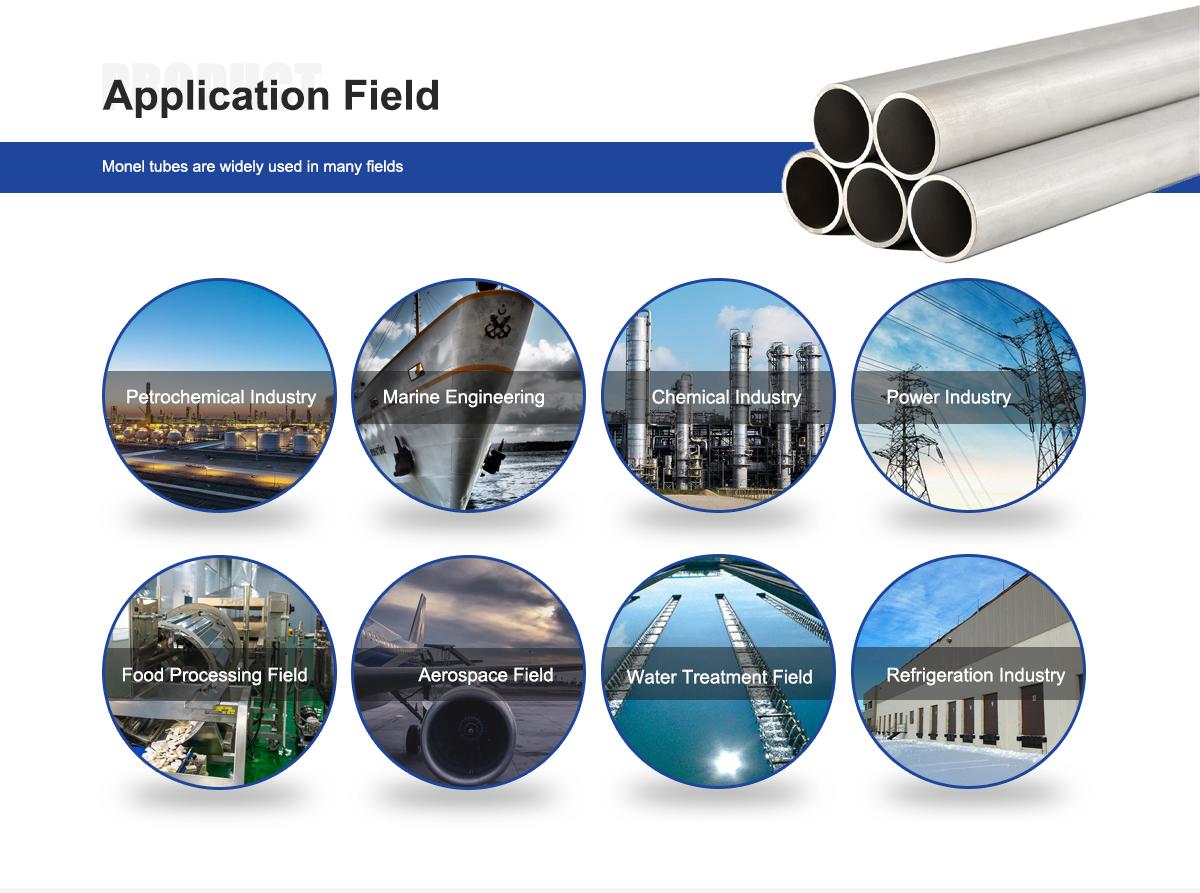

When it comes to applications, our durable Monel 400 alloy tubing is incredibly versatile, fitting seamlessly into aerospace and oil and gas sectors. In aerospace, it's a staple for components that face constant vibration and thermal cycling. Think about fuel delivery systems in jets—our tubing ensures safe, leak-free performance under high pressures. It's also used in landing gear hydraulics and environmental control systems, where its low magnetic permeability prevents interference with avionics. For oil and gas, Monel 400 tubing is ideal for downhole tools, subsea pipelines, and refinery equipment. It resists the corrosive effects of brine and CO2, which are common in extraction processes, helping to avoid costly shutdowns. Beyond these core areas, we've supplied it for marine engineering, like ship propellers and desalination plants, where its resistance to saltwater erosion is unmatched. In chemical plants, it handles aggressive media in heat exchangers and valves. Even in emerging fields like renewable energy, such as wave energy converters or geothermal wells, our tubing provides the durability needed for long-term viability. The beauty of Monel 400 alloy tubing is its adaptability—we can customize diameters, wall thicknesses, and lengths to fit your exact specs, whether it's seamless for high-pressure apps or welded for cost efficiency.

Comparison Parameters Table

| Parameter | Monel 400 Alloy Tubing | Stainless Steel 316 | Copper-Nickel Alloys (e.g., 90/10 Cu-Ni) |

|---|---|---|---|

| Composition | 63% Ni, 28-34% Cu | 16-18% Cr, 10-14% Ni, 2-3% Mo | 90% Cu, 10% Ni |

| Density (g/cm³) | 8.8 | 8.0 | 8.9 |

| Tensile Strength (ksi) | 70-85 | 75-90 | 40-60 |

| Yield Strength (ksi) | 25-50 | 30-40 | 15-30 |

| Corrosion Resistance | Excellent in seawater, acids, alkalis; resistant to pitting and stress cracking | Good in chlorides, but prone to pitting in seawater | Good in seawater, but lower resistance to acids and high-velocity flow |

| Temperature Range (°F) | -200 to 1000 | -320 to 1500 | -100 to 750 |

| Weldability | Excellent | Good | Fair |

| Cost Factor | Higher due to nickel content | Moderate | Lower |

| Typical Applications | Aerospace, oil & gas, marine | Food processing, medical | Marine piping, heat exchangers |

Of course, not all suppliers are created equal, and that's where our company truly shines. We focus on delivering superior quality Monel 400 tubing that goes beyond industry standards. Our manufacturing process incorporates advanced quality controls, from raw material sourcing to final testing, ensuring every piece meets ASTM B165 or ASME SB-165 specifications. What sets us apart is our commitment to innovation—we invest in state-of-the-art extrusion and annealing techniques that enhance the tubing's uniformity and surface finish, reducing the risk of defects that could lead to failures in critical environments. Compared to generic offerings out there, our durable Monel 400 alloy tubing features tighter tolerances and better fatigue resistance, thanks to our proprietary heat treatment methods. We also prioritize sustainability, using recycled nickel where possible to lower our carbon footprint without compromising performance. Customer service is another big win for us; we offer rapid prototyping, just-in-time delivery, and technical support from metallurgists who know Monel 400 inside out. If you're dealing with a complex aerospace project, our team can collaborate on custom alloys or coatings to boost performance further. In oil and gas, we've helped clients cut downtime by 30% through tailored tubing solutions that withstand extreme H2S levels. And let's not forget pricing—we keep it competitive by optimizing our supply chain, passing savings directly to you while maintaining top-tier quality.

But why choose our Monel 400 tubing over alternatives? Simply put, it offers a unique balance of properties that few materials can match. Its corrosion resistance in marine and acidic settings is superior, often lasting twice as long as stainless steels in similar conditions. For aerospace, the lightweight yet strong nature helps with fuel efficiency, aligning with industry goals for greener aviation. In oil and gas, it reduces the need for protective coatings, saving on maintenance. We've seen firsthand how our tubing performs in real tests—lab simulations show it enduring 10,000 hours in saltwater without significant degradation, far outpacing common copper-nickel blends. Trends wise, as the push for net-zero emissions intensifies, materials like ours that enable safer, more efficient operations are in high demand. We're ahead of the curve, partnering with research institutions to explore Monel 400's potential in hydrogen infrastructure, where its resistance to embrittlement is a game-changer.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Monel 400 alloy made of?

Monel 400 is a nickel-copper alloy consisting of approximately 63% nickel, 28-34% copper, with small amounts of iron, manganese, carbon, and silicon.What are the key properties of Monel 400 tubing?

It offers excellent corrosion resistance, high strength (tensile strength of 70-85 ksi), good ductility, weldability, and performance from subzero temperatures up to 1000°F.What applications is Monel 400 tubing used for in aerospace?

It's used in aircraft fuel lines, hydraulic systems, and structural components due to its resistance to high-stress and corrosive environments.How does Monel 400 perform in oil and gas environments?

It excels in downhole tubing, valves, and pipelines, resisting sour gas, seawater, and acidic conditions without pitting or stress corrosion cracking.What industry trends are driving demand for Monel 400?

Growing offshore exploration, renewable energy projects like desalination, and stricter environmental regulations are increasing its use for durable, low-maintenance materials.Is Monel 400 tubing resistant to corrosion in marine settings?

Yes, it has a low corrosion rate in flowing seawater and resists biofouling, making it ideal for shipbuilding and offshore structures.What are the mechanical advantages of Monel 400 over standard alloys?

It maintains strength and hardness at subzero temperatures with minimal loss in ductility, outperforming many materials in cryogenic applications.How is Monel 400 tubing processed for custom applications?

It can be easily formed, machined, and welded, allowing for seamless tubing in various diameters and lengths tailored to specific industry needs.