High-Strength Monel 400 Tube for Marine and Chemical Processing Applications

Monel 400 Tube is one of our flagship products, and we’re proud to offer a material that’s tough, reliable, and built to last in some of the harshest environments out there. As a leading supplier in the industry, we’ve seen firsthand how this high-strength nickel-copper alloy transforms applications in marine engineering, chemical processing, and beyond. Let’s dive into what makes Monel 400 Tube so special, explore the industries it serves, and highlight why our company stands out as your go-to source for this versatile material.

For more details, pls directly contact us.

Monel 400 Tube is a nickel-copper alloy, typically composed of 63-70% nickel and 28-34% copper, with small additions of iron, manganese, carbon, and silicon. This unique blend gives it exceptional corrosion resistance, high strength, and excellent mechanical properties across a wide temperature range, from sub-zero to 1000°F (538°C). Unlike other alloys, Monel 400 doesn’t undergo a ductile-to-brittle transition even at cryogenic temperatures, making it a top choice for demanding applications.

We craft our Monel 400 Tubes with precision, ensuring they meet industry standards like ASTM B165 and BS3074NA18 for seamless tubes. Whether you need seamless, welded, hot-rolled, or cold-drawn tubes, we’ve got you covered with a range of sizes and forms to suit your project’s needs. The alloy’s ability to resist corrosion in seawater, acids, and alkalis, combined with its weldability and formability, makes it a go-to material for industries that can’t afford to compromise on durability.

Parameter:

Item | Ni | Cu | Fe | Mn | C | Si | S |

Monel 400 | ≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Ni | Cu | Al | Ti | Fe | Mn | S | C | Si |

Monel K500 | ≥63 | 27-33 | 2.3-3.15 | 0.35-0.85 | ≤2 | ≤1.5 | ≤0.01 | ≤0.25 | ≤0.5 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation |

Monel K500 | 8.05 g/cm3 | 1288-1343℃ | 1100 | 790 | 20% |

Monel 400 | Bar / Rod | Forging | Pipe | Sheet / Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

Monel K500 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B864 | AMS4676 | ASTM B865 | ASTM B564 | ErNiCu-7 |

For more details, pls directly contact us.

Let’s talk about why Monel 400 Tube is such a game-changer. First off, its corrosion resistance is off the charts. Whether it’s fast-moving seawater, hydrofluoric acid, or alkaline solutions, this alloy holds its own where others, like standard stainless steel, might falter. That’s why it’s a favorite in marine and chemical processing environments. It’s also got great mechanical properties—think high tensile strength (around 550 MPa in annealed condition) and good ductility, which means it can take a beating without cracking or losing its shape.

Another big plus? Monel 400 Tube is easy to work with. You can weld it, form it, and machine it (though it does work-harden, so we recommend sharp tools and slow feeds). It’s also non-magnetic in most cases, which is a huge advantage for applications like navigation systems or electronic components. And let’s not forget its thermal conductivity, which makes it a stellar choice for heat exchangers and steam-generator tubing.

Comparison Table: Monel 400 Tube vs. Stainless Steel (316) and Inconel 600

Parameter | Monel 400 Tube | Stainless Steel 316 | Inconel 600 |

|---|---|---|---|

Composition | 63-70% Ni, 28-34% Cu, trace Fe, Mn, C, Si | 16-18% Cr, 10-14% Ni, 2-3% Mo, Fe balance | 72% Ni, 14-17% Cr, 6-10% Fe |

Corrosion Resistance | Excellent in seawater, acids, alkalis | Good in mild environments, less in seawater | Excellent in high-temperature oxidation |

Tensile Strength | ~550 MPa (annealed) | ~515 MPa (annealed) | ~655 MPa (annealed) |

Yield Strength | ~240 MPa (annealed) | ~205 MPa (annealed) | ~310 MPa (annealed) |

Temperature Range | -300°F to 1000°F (-184°C to 538°C) | -150°F to 1500°F (-101°C to 816°C) | Up to 2000°F (1093°C) |

Density | 8.80 g/cm³ | 8.00 g/cm³ | 8.47 g/cm³ |

Weldability | Excellent, standard techniques | Good, standard techniques | Good, requires care at high temperatures |

Cost | Higher due to nickel content | More cost-effective | Higher than Monel 400 |

Applications | Marine, chemical processing, oil & gas | General industrial, food processing | High-temperature, aerospace, nuclear |

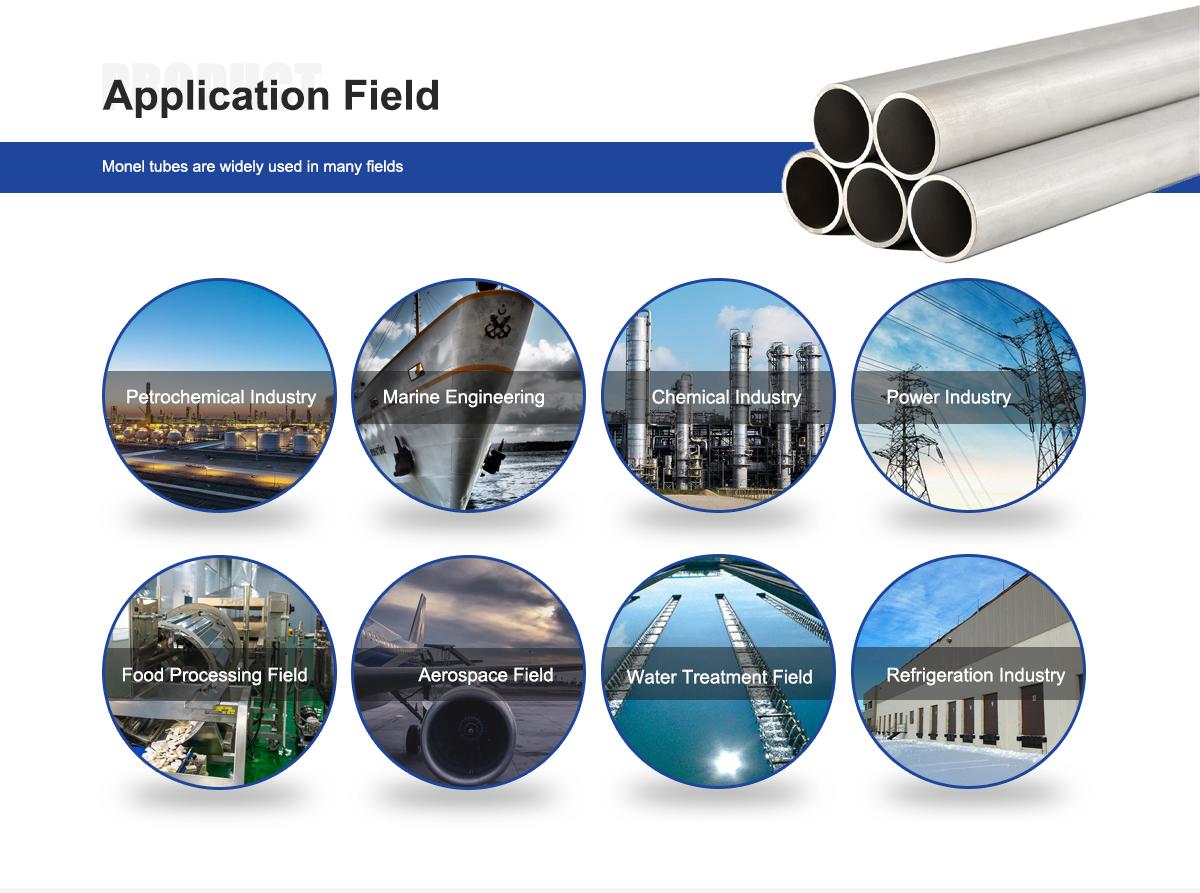

Monel 400 Tube shines in industries where conditions are tough and failure isn’t an option. Here’s a breakdown of where it’s making a difference:

In the marine world, saltwater is the ultimate test of a material’s durability. Monel 400 Tube passes with flying colors, resisting corrosion from fast-moving seawater and brackish water. It’s used in propeller shafts, pump shafts, seawater valves, and piping systems on ships and offshore platforms. Its toughness and non-magnetic properties also make it ideal for navigation equipment like compass housings.

Chemical plants deal with some of the most corrosive substances out there—think sulfuric acid, hydrofluoric acid, and alkalis. Monel 400 Tube is a rockstar in these environments, used in heat exchangers, evaporators, pressure vessels, and process piping. Its ability to resist stress corrosion cracking ensures equipment stays reliable, even under high-pressure conditions.

The oil and gas industry relies on Monel 400 Tube for its ability to withstand harsh environments, like sour-gas conditions and high-velocity seawater. You’ll find it in pump components, valve stems, and tubing for offshore drilling towers. Its high strength and corrosion resistance help reduce downtime and maintenance costs, which is a big deal in this industry.

Monel 400 Tube isn’t just for wet environments—it’s also used in aerospace for wiring and components that need to handle high temperatures and corrosive conditions. Back in the 1960s, it was a key material in experimental rocket planes like the North American X-15, thanks to its ability to resist heat from aerodynamic friction.

In power plants, Monel 400 Tube is used in feed-water heaters, steam-generator tubing, and brine heaters. Its thermal conductivity and resistance to steam and seawater make it a reliable choice for keeping systems running smoothly.

Industry Trends Driving Monel 400 Tube Demand

The demand for Monel 400 Tube is on the rise, and we’re keeping our finger on the pulse of what’s driving it. One major trend is the push for sustainability in industries like oil and gas and marine engineering. Companies are looking for materials that last longer and reduce the need for frequent replacements, which cuts down on waste and costs. Monel 400’s exceptional longevity in corrosive environments fits the bill perfectly.

Another trend is the growth of offshore energy projects, like wind farms and deep-sea oil exploration. These projects expose equipment to harsh marine conditions, and Monel 400 Tube is increasingly specified for its proven performance in seawater. The chemical processing industry is also seeing a shift toward more aggressive chemicals to meet production demands, and Monel 400’s ability to handle acids and alkalis makes it a go-to choice.

Additive manufacturing is another area to watch. While Monel 400 is traditionally used in tube, sheet, and bar forms, advances in 3D printing are opening up new possibilities for custom components made from nickel-copper alloys. We’re exploring how to integrate these technologies to offer even more tailored solutions to our customers.

Why Choose Our Monel 400 Tube?

When it comes to Monel 400 Tube, we’re not just another supplier—we’re a partner you can trust. Here’s why our company stands out:

Unmatched Quality: Our Monel 400 Tubes are manufactured to meet stringent standards like ASTM B165 and ISO 6208, ensuring consistent performance. We source our materials from top-tier mills and conduct rigorous quality checks to guarantee you get the best.

Custom Solutions: Need a specific size, thickness, or finish? We offer seamless, welded, hot-rolled, and cold-drawn tubes tailored to your project. Our team works with you to deliver exactly what you need, no matter how complex.

Fast Delivery: With distribution centers strategically located across the U.S., we ensure quick turnaround times. Whether you’re in Florida, Texas, or California, we’ve got you covered with fast, reliable shipping.

Expert Support: Our team has decades of experience in nickel alloys and can answer any question, from material selection to fabrication tips. We’re here to make your project a success.

Competitive Pricing: While Monel 400 is a premium alloy, we keep our pricing competitive without cutting corners on quality. You get top-notch materials at a fair price.

Sustainability Focus: We prioritize eco-friendly practices, from sourcing to manufacturing, to help you meet your sustainability goals without sacrificing performance.

Compared to others in the market, our commitment to quality, customization, and customer service sets us apart. Some suppliers cut costs by using lower-grade materials or skipping quality checks, which can lead to failures in critical applications. We don’t take shortcuts—our Monel 400 Tubes are built to perform, every time.

Challenges and Considerations

Monel 400 Tube isn’t perfect for every situation, and we’re upfront about that. Its high nickel content makes it more expensive than stainless steel, so it’s best suited for applications where corrosion resistance and strength are non-negotiable. It also work-hardens during machining, which can wear tools faster if not handled properly. Our team provides guidance on machining techniques to minimize these challenges, ensuring you get the most out of the material.

Another consideration is that Monel 400 can develop slight magnetism under certain conditions, which might affect applications requiring strict non-magnetic properties. We test our tubes to ensure they meet your specifications, and we can recommend alternatives like Monel K-500 for applications needing enhanced strength or guaranteed non-magnetic performance.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Monel 400 Tube made of?

Monel 400 Tube is a nickel-copper alloy, typically containing 63-70% nickel, 28-34% copper, with small amounts of iron, manganese, carbon, and silicon.What makes Monel 400 Tube corrosion-resistant?

Its high nickel and copper content provides excellent resistance to seawater, acids, alkalis, and other corrosive environments.What industries use Monel 400 Tube?

It’s widely used in marine engineering, chemical processing, oil and gas, aerospace, and power generation.Can Monel 400 Tube withstand high temperatures?

Yes, it maintains strength and toughness from sub-zero temperatures up to 1000°F (538°C).Is Monel 400 Tube suitable for welding?

Absolutely, it can be welded using standard techniques, making it ideal for fabricating complex components.What are the key applications of Monel 400 Tube?

It’s used in heat exchangers, piping systems, pump shafts, valves, and chemical processing equipment.Is Monel 400 Tube non-magnetic?

Yes, it’s generally non-magnetic, though slight magnetism may occur depending on composition and processing.How does Monel 400 Tube compare to stainless steel?

Monel 400 offers superior corrosion resistance in harsh environments like seawater, but it’s more expensive than stainless steel.