Durable Monel Multilayer Tube for Chemical Processing Systems

Monel multilayer tubes have become a trusted choice for industries where durability, corrosion resistance, and reliability are non-negotiable. As a company specializing in high-performance alloy solutions, we have seen first-hand how this material transforms chemical processing systems by extending service life, reducing maintenance downtime, and ensuring consistent performance under extreme conditions. This isn’t just another alloy tube — it’s a precision-engineered component designed for critical industrial applications.

For more details, pls directly contact us.

The Monel alloy used in multilayer tubes is primarily a nickel-copper alloy with excellent resistance to corrosion from acids, alkalis, and seawater. The addition of small amounts of iron, manganese, and silicon improves its mechanical properties without compromising its corrosion resistance. The multilayer construction further enhances durability, offering extra safety margins for pressure, temperature, and chemical exposure. This makes it ideal for industries where safety and reliability are paramount.

Parameter:

|

Item |

Ni |

Cu |

Fe |

Mn |

C |

Si |

S |

|

≥63 |

28-34 |

≤2.5 |

≤2 |

≤0.3 |

≤0.5 |

≤0.025 |

|

Item |

Ni |

Cu |

Al |

Ti |

Fe |

Mn |

S |

C |

Si |

|

Monel K500 |

≥63 |

27-33 |

2.3-3.15 |

0.35-0.85 |

≤2 |

≤1.5 |

≤0.01 |

≤0.25 |

≤0.5 |

|

Item |

Density |

Melting point |

Tensile Strength |

Yield Strength |

Elongation |

HB |

|

Monel 400 |

8.83 g/cm3 |

1300-1390℃ |

480 |

170 |

35% |

≥331 |

|

Item |

Density |

Melting point |

Tensile Strength |

Yield Strength |

Elongation |

|

Monel K500 |

8.05 g/cm3 |

1288-1343℃ |

1100 |

790 |

20% |

|

Monel 400 |

Bar / Rod |

Forging |

Pipe |

Sheet / Strip |

Welding Wire |

|

Standard |

ASTM B164 |

ASTM B564 |

ASTM B165 |

ASTM B127 |

ErNiCu-7 |

|

Monel K500 |

Bar/Rod |

Forging |

Pipe |

Sheet/Strip |

Welding Wire |

|

Standard |

ASTM B864 |

AMS4676 |

ASTM B865 |

ASTM B564 |

ErNiCu-7 |

For more details, pls directly contact us.

Chemical processing systems often handle aggressive media such as hydrochloric acid, sulfuric acid, or high-salinity water. Monel’s corrosion resistance is particularly strong in these conditions, outperforming many stainless steels in environments rich in chlorides or where pitting and crevice corrosion are concerns. The multilayer tube design acts as an added safeguard, ensuring that even in the rare case of surface wear, the structural integrity of the tube remains intact.

Performance in Chemical Processing Systems

In our experience supplying Monel multilayer tubes to chemical processing plants, customers value three main aspects:

-

Long service life – The alloy resists degradation over years of constant use.

-

Operational safety – The multilayer design minimizes the risk of catastrophic failure.

-

Low maintenance costs – With fewer corrosion-related replacements, overall operational costs drop.

These factors translate into tangible benefits for operators, from uninterrupted production schedules to improved worker safety.

Manufacturing Process and Quality Control

Our production of Monel multilayer tubes begins with precision selection of raw materials, ensuring chemical composition meets strict industrial standards. Tubes are cold-drawn or seamless extruded depending on the required specifications, with layers applied through advanced metallurgical bonding techniques. Each tube undergoes rigorous non-destructive testing, including ultrasonic and eddy current inspections, to verify the absence of cracks, voids, or inclusions.

Dimensional accuracy is maintained within tight tolerances, allowing our tubes to integrate seamlessly into complex system assemblies. We also provide surface finishing options tailored to specific chemical environments, from polished interiors for reduced flow resistance to special passivation treatments for additional corrosion protection.

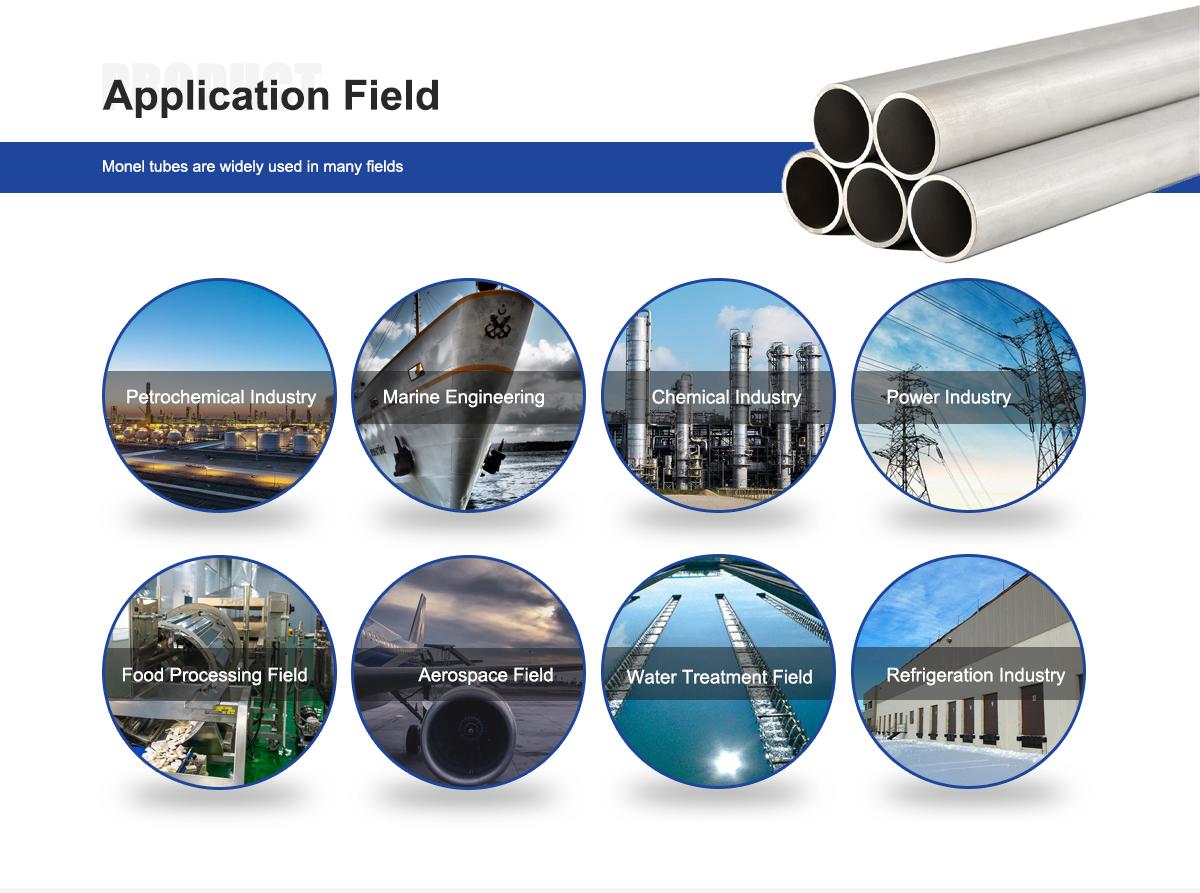

Applications Beyond Chemical Processing

While chemical processing systems are the primary application, Monel multilayer tubes are equally valuable in:

-

Marine engineering – For seawater cooling and desalination systems

-

Oil & gas – In offshore platforms and sour gas environments

-

Aerospace – For high-strength, corrosion-resistant fuel and hydraulic lines

-

Power generation – In condensers and heat exchangers exposed to brackish water

These industries face similar challenges: aggressive media, fluctuating temperatures, and high mechanical stress. Monel’s performance consistency across these environments makes it a versatile choice.

Industry Trends Driving Demand

The demand for Monel multilayer tubes is growing as industries adopt stricter safety and environmental regulations. Plants are expected to run longer between maintenance shutdowns, making material reliability critical. Another factor is the global trend toward higher process intensities — meaning higher pressures, higher temperatures, and more aggressive chemistries — which require advanced materials capable of sustaining these conditions without premature failure.

Environmental sustainability is also influencing material selection. Longer-lasting materials like Monel reduce the need for frequent replacements, which in turn lowers resource consumption and waste generation. In some cases, using Monel has allowed facilities to operate more efficiently, consuming less energy due to improved flow dynamics and reduced fouling.

Comparison Table – Material Parameters

| Property | Monel Multilayer Tube | Stainless Steel Tube | Titanium Alloy Tube |

|---|---|---|---|

| Main Composition | Ni-Cu Alloy | Fe-Cr-Ni Alloy | Ti with Al/V |

| Corrosion Resistance | Excellent in acids, alkalis, and seawater | Good in many environments | Excellent in seawater and chlorides |

| Max Operating Temperature | ~480°C | ~600°C | ~315°C |

| Mechanical Strength | High | High | Medium-High |

| Density (g/cm³) | 8.8 | 7.9 | 4.5 |

| Weldability | Good | Good | Good |

| Cost Level | High | Medium | High |

| Typical Applications | Chemical processing, marine systems | General industry, construction | Aerospace, marine |

Where we differentiate ourselves is in the combination of technical expertise, customization capability, and after-sales support. We don’t simply deliver tubes — we provide engineered solutions. This involves:

-

Custom dimensions and tolerances to meet unique system designs

-

Specialized multilayer configurations optimized for target media and temperature ranges

-

Integrated quality documentation for regulatory compliance and project traceability

-

On-site technical support for installation and maintenance planning

Our in-house metallurgists work directly with customers to select the optimal Monel grade, layer configuration, and finishing process for their specific application. This consultative approach ensures that every product delivers maximum value over its lifetime.

Customer Case Study: Improving Plant Reliability

One of our clients in the chemical processing sector was facing frequent unscheduled shutdowns due to corrosion-related tube failures. Switching to our Monel multilayer tubes solved the problem. Over a five-year monitoring period, the tubes maintained full integrity with no recorded leaks or performance drop. The result was a 30% reduction in maintenance costs and improved plant output stability.

Installation and Maintenance Tips

Even though Monel multilayer tubes are highly resistant to corrosion, best practices in installation and maintenance can further extend their service life:

-

Ensure correct alignment and support to prevent mechanical stress

-

Avoid mixing with incompatible metals in the same system to reduce galvanic corrosion risk

-

Conduct periodic inspections to detect early signs of surface fouling or scaling

-

Use compatible welding and joining methods to maintain corrosion resistance in joints

Following these guidelines can help maximize the performance benefits of Monel multilayer tubes.

Future Outlook for Monel Multilayer Tubes

Looking ahead, we expect further advancements in multilayer manufacturing technologies. These could include enhanced diffusion bonding processes, thinner yet stronger layer construction, and even hybrid alloy combinations for extreme niche environments. As global chemical processing systems become more complex and demanding, the role of premium materials like Monel will only grow.

The ongoing shift toward renewable energy and environmental protection is also likely to create new markets. For example, Monel multilayer tubes could see increased use in green hydrogen production, where durability and purity control are essential.

Final Thoughts

Durable Monel multilayer tubes are more than just an industrial component — they’re a strategic investment in system reliability, safety, and operational efficiency. In chemical processing systems, where downtime is costly and safety is critical, this material delivers proven performance year after year. By partnering with a supplier that understands both the metallurgy and the real-world operational demands, companies can secure the long-term advantages that Monel multilayer tubes offer.

We take pride in delivering solutions that exceed expectations, combining robust material properties with precision manufacturing and responsive support. Our mission is to ensure that every meter of Monel multilayer tube we supply contributes to safer, more efficient, and more sustainable industrial operations worldwide.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the primary composition of Monel alloy?

Nickel and copper with small amounts of iron, manganese, carbon, and silicon. -

Is Monel multilayer tube suitable for high-temperature chemical processes?

Yes. -

Can Monel multilayer tube resist strong acids and alkalis?

Yes. -

Does Monel multilayer tube have high mechanical strength?

Yes. -

Is Monel multilayer tube applicable in marine chemical systems?

Yes. -

Can Monel multilayer tube be customized in wall thickness and diameter?

Yes. -

Does Monel multilayer tube offer good fatigue resistance?

Yes. -

Is welding possible for Monel multilayer tube?

Yes.