Non-Magnetic Monel 400 Multilayer Tube for Precision Engineering

We’re thrilled to showcase our Non-Magnetic Monel 400 Multilayer Tube, a standout product engineered for the exacting demands of precision engineering. This isn’t just a tube—it’s a precision-crafted solution that leverages the unique properties of Monel 400, a nickel-copper alloy, combined with an innovative multilayer design. Our tubes deliver unmatched non-magnetic performance, corrosion resistance, and durability, making them the go-to choice for industries where precision is non-negotiable. Let’s dive into what makes this product special, explore its role in the industry, and show why our company is your best partner for this game-changing technology.

For more details, pls directly contact us.

Our Non-Magnetic Monel 400 Multilayer Tube is built from Monel 400, a nickel-copper alloy with roughly 63-67% nickel and 28-34% copper. Known for its non-magnetic properties, high strength, and exceptional corrosion resistance, Monel 400 is already a star in high-performance applications. But we’ve taken it further with our multilayer design, which layers Monel with complementary materials to boost mechanical strength, thermal stability, and resistance to stress corrosion cracking. The result? A tube that’s tough, reliable, and perfectly suited for precision engineering.

What makes these tubes stand out is their non-magnetic nature, which eliminates interference in sensitive equipment like sensors, medical imaging devices, and aerospace instruments. They maintain structural integrity across a wide temperature range, from sub-zero conditions to 1000°C, and resist corrosion from harsh environments like seawater, acids, and alkalis. With a tensile strength of 517–620 MPa, they’re built to handle high-stress applications without compromising flexibility or workability.

Our tubes are designed for ease of use, offering excellent weldability and formability to meet the tight tolerances required in precision engineering. Compliant with standards like ASTM B165 and ASME SB165, they’re rigorously tested—using methods like hydrostatic and ultrasonic testing—to ensure flawless performance. Whether you’re crafting intricate medical devices or robust aerospace components, our Non-Magnetic Monel 400 Multilayer Tubes deliver the precision and reliability you need.

Parameter:

Item | Ni | Cu | Fe | Mn | C | Si | S |

Monel 400 | ≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Ni | Cu | Al | Ti | Fe | Mn | S | C | Si |

Monel K500 | ≥63 | 27-33 | 2.3-3.15 | 0.35-0.85 | ≤2 | ≤1.5 | ≤0.01 | ≤0.25 | ≤0.5 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation |

Monel K500 | 8.05 g/cm3 | 1288-1343℃ | 1100 | 790 | 20% |

Monel 400 | Bar / Rod | Forging | Pipe | Sheet / Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

Monel K500 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B864 | AMS4676 | ASTM B865 | ASTM B564 | ErNiCu-7 |

For more details, pls directly contact us.

The precision engineering sector is booming, driven by advancements in aerospace, medical technology, electronics, and marine industries. As devices become smaller, smarter, and more complex, the demand for materials that can deliver high performance in compact, sensitive systems is growing. Non-magnetic materials are particularly critical in applications like MRI machines, navigation systems, and precision sensors, where magnetic interference can disrupt functionality. Our Non-Magnetic Monel 400 Multilayer Tubes are perfectly positioned to meet these needs, offering a unique combination of strength, corrosion resistance, and non-magnetic properties.

Industry trends point to a growing emphasis on materials that can withstand extreme conditions while maintaining precision. For example, aerospace applications require components that perform reliably in high-stress, corrosive environments, while medical devices need materials that are biocompatible and non-magnetic. The global market for high-performance alloys is expanding, with projections indicating strong growth as industries prioritize durability, sustainability, and efficiency.

Sustainability is another key driver. Long-lasting materials like our Monel 400 tubes reduce the need for frequent replacements, cutting costs and environmental impact. Their corrosion resistance also makes them ideal for marine applications, where exposure to seawater is a constant challenge. Meanwhile, the push for lightweight materials in aerospace and electronics aligns with our tubes’ optimized strength-to-weight ratio, making them a smart choice for engineers looking to balance performance and efficiency.

The competitive landscape is crowded, but our multilayer design gives us a clear advantage. While other alloys may offer similar properties, they often lack the non-magnetic performance or enhanced durability of our tubes. As precision engineering continues to evolve, our Non-Magnetic Monel 400 Multilayer Tubes are set to lead the way, meeting the industry’s toughest challenges with ease.

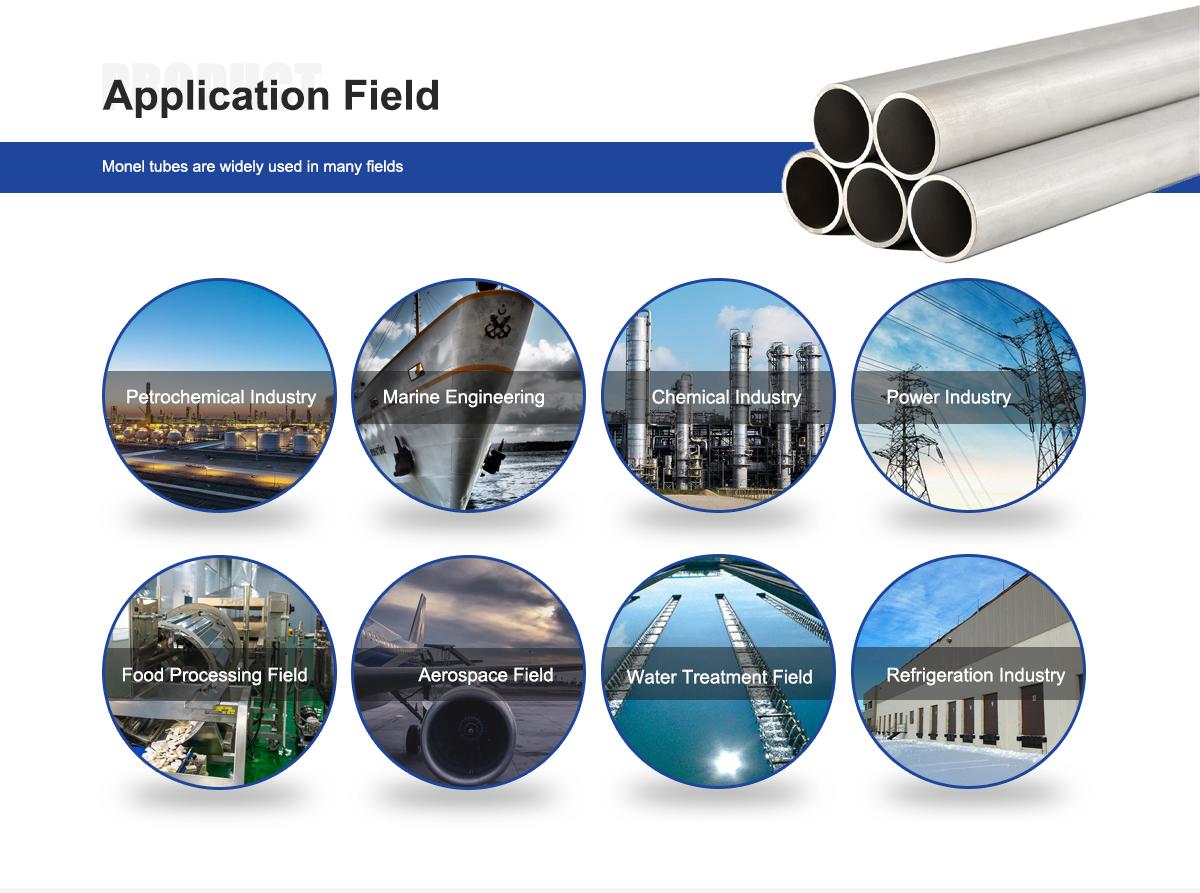

Applications: Where Our Tubes Make a Difference

Our Non-Magnetic Monel 400 Multilayer Tubes are built for versatility, shining in applications where precision, durability, and non-magnetic properties are critical. Here’s where they excel:

Aerospace Instruments: Used in navigation systems, sensors, and avionics, our tubes ensure no magnetic interference while withstanding high temperatures and corrosive conditions.

Medical Devices: From MRI components to surgical instruments, their non-magnetic and biocompatible properties make them ideal for sensitive medical applications.

Precision Sensors: In electronics and industrial systems, our tubes provide reliable performance in sensors that require non-magnetic materials to avoid signal distortion.

Marine Systems: Their resistance to seawater corrosion makes them perfect for underwater equipment, piping, and structural components in marine engineering.

Chemical Processing: Handling aggressive chemicals? Our tubes resist corrosion from acids and alkalis, ensuring long-term reliability in processing plants.

Beyond these core applications, our tubes are also used in oil and gas systems, where their durability and corrosion resistance tackle harsh environments, and in electronics, where precision and non-magnetic properties are paramount. Their versatility makes them a favorite across industries that demand high performance in challenging conditions.

Company Comparison: Why We’re the Best Choice

We know you have options, but our Non-Magnetic Monel 400 Multilayer Tubes stand head and shoulders above the rest. Here’s why partnering with us is the smart move:

Innovative Multilayer Design: Our tubes aren’t just Monel 400—they’re enhanced with a multilayer structure that boosts strength, corrosion resistance, and thermal stability. Other materials might offer non-magnetic properties, but they can’t match our tubes’ specialized performance.

Top-Tier Quality: We adhere to strict standards like ASTM B165 and ASME SB165, with rigorous testing to ensure every tube is defect-free. Our commitment to quality means you get reliable, high-performing products every time.

Custom Solutions: Precision engineering demands flexibility, and we deliver. We customize tube dimensions, wall thicknesses, and configurations to meet your exact specifications, ensuring a perfect fit for your project.

Sustainability Edge: Our tubes are built to last, reducing maintenance and replacement costs. Their durability aligns with the industry’s push for sustainable, long-life components, saving you money and reducing environmental impact.

Unmatched Expertise: With deep experience in high-performance alloys, our team offers technical support that goes beyond the sale. From material selection to application guidance, we’re here to help you succeed.

Other suppliers might offer similar alloys, but their products often lack the non-magnetic performance, multilayer durability, or customization options we provide. Our focus on precision, quality, and client collaboration sets us apart, making us the partner you can trust for your most demanding projects.

Comparison Parameters Table

Parameter | Non-Magnetic Monel 400 Multilayer Tube | Other Nickel-Based Alloys |

|---|---|---|

Composition | Nickel (63-67%), Copper (28-34%), multilayer | Nickel, Chromium, Iron, varying compositions |

Magnetic Properties | Non-magnetic | Often magnetic or partially magnetic |

Corrosion Resistance | Excellent in seawater, acids, alkalis | Good, but less effective in marine settings |

Temperature Range | -50°C to 1000°C | 0°C to 800-1000°C (varies by alloy) |

Mechanical Strength | High tensile strength (517–620 MPa) | Moderate to high (400–900 MPa, varies) |

Workability | Superior weldability, formability | Moderate, may require specialized techniques |

Applications | Precision sensors, medical devices, aerospace | General engineering, less precision-focused |

Cost | Moderate, reflects multilayer design benefits | Often lower, but less specialized |

Our Non-Magnetic Monel 400 Multilayer Tubes are more than just a product—they’re a solution to the precision engineering world’s toughest challenges. Their non-magnetic properties, corrosion resistance, and multilayer strength make them ideal for applications where performance can’t be compromised. Whether you’re building aerospace sensors, medical devices, or marine systems, our tubes deliver the reliability and precision you need.

We’re proud to lead the charge in high-performance materials, and our Non-Magnetic Monel 400 Multilayer Tubes are proof of our commitment to innovation and excellence. With a focus on quality, customization, and sustainability, we’re not just meeting industry demands—we’re setting the standard. Ready to take your precision engineering project to the next level? Our tubes are here to make it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is a Non-Magnetic Monel 400 multilayer tube?

It’s a high-performance tube made from Monel 400, a non-magnetic nickel-copper alloy, with a multilayer design for enhanced strength, corrosion resistance, and precision in engineering applications.Why is non-magnetic Monel 400 ideal for precision engineering?

Its non-magnetic properties prevent interference in sensitive equipment, while its corrosion resistance and strength ensure reliability in high-precision components.What are the main applications of these tubes?

They’re used in aerospace instruments, medical devices, precision sensors, and marine systems where non-magnetic properties and durability are critical.How does the multilayer design benefit performance?

The multilayer structure improves mechanical strength, corrosion resistance, and thermal stability, making it perfect for demanding precision engineering tasks.What environments can these tubes withstand?

They resist corrosion from seawater, acids, and alkalis, and perform reliably in temperatures ranging from sub-zero to 1000°C.Are these tubes easy to work with?

Yes, they offer excellent weldability and formability, allowing for precise shaping and integration into complex engineering designs.How do Non-Magnetic Monel 400 tubes compare to other materials?

They outperform many alloys in non-magnetic applications, offering superior corrosion resistance and workability in precision environments.Which industries use these tubes?

Aerospace, medical, marine, and electronics industries rely on them for their non-magnetic properties and high durability in critical applications.