Corrosion-Resistant Incoloy 800 Wire for Petrochemical and Power Generation

In the world of heavy industry, performance depends on materials that can withstand the harshest conditions. Petrochemical plants and power generation facilities operate in high-temperature, corrosive environments that push conventional metals to their limits. When equipment fails under these stresses, the costs are massive—both in downtime and repairs. This is where Incoloy 800 wire becomes an essential solution.

As a nickel-iron-chromium alloy, Incoloy 800 wire was engineered to combine high-temperature strength with corrosion resistance. It has become a staple in industries that rely on stability under extreme heat, oxidation, and carburization. Our company specializes in manufacturing and supplying Incoloy 800 wire, delivering tailored solutions that meet the stringent demands of global petrochemical and energy operations.

Incoloy 800 is built on a solid balance of nickel, iron, and chromium, with smaller additions of aluminum, titanium, and carbon. This composition provides strength and stability in prolonged high-temperature service. The nickel content gives the wire resistance against chloride stress corrosion cracking, while chromium ensures excellent oxidation resistance. Additions of aluminum and titanium further enhance stability by forming a protective oxide scale.

The result is a wire that not only maintains mechanical properties but also resists scaling and surface degradation even in continuous service at temperatures up to 1100°C (2010°F).

For more details, pls directly contact us.

The petrochemical industry is one of the largest consumers of Incoloy 800 wire. From reformers and cracking units to heat exchangers and gas furnaces, the wire plays a crucial role in ensuring continuous, reliable operations.

Heater coils and furnace elements: Incoloy 800 wire is used to form coils and grids for process heaters exposed to high-temperature gases.

Heat exchangers: Stability in both oxidizing and reducing environments makes the alloy ideal for heat exchanger tubing and wire reinforcement.

Process equipment reinforcement: Wires serve as supports and mesh structures in reactors and other equipment where strength and corrosion resistance are vital.

The resistance of Incoloy 800 wire to sulfidation, carburization, and oxidation makes it indispensable in chemical processes where carbon- and sulfur-rich atmospheres are common.

Power plants—both conventional and modern—rely heavily on Incoloy 800 wire for components exposed to heat and corrosive gases.

Boilers and superheaters: The alloy’s stability at elevated temperatures ensures safety and efficiency in continuous high-heat environments.

Turbine systems: Supporting structures, seals, and heating elements made from Incoloy 800 wire enhance turbine durability.

Nuclear applications: With its resistance to stress corrosion cracking, the wire is also used in steam generators and reactor components.

The ability of Incoloy 800 wire to resist degradation in mixed oxidizing and reducing conditions ensures that power plants maintain consistent performance, minimizing interruptions.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Several global trends are fueling demand for Incoloy 800 wire:

Expansion of petrochemical capacity: As developing nations build new plants, demand for corrosion-resistant alloys is rising.

Growing energy demand: Power plants worldwide are upgrading equipment with materials that can handle higher loads and longer operating cycles.

Focus on sustainability: Industries are seeking alloys that reduce maintenance and replacement frequency, lowering their environmental footprint.

Tougher safety regulations: Governments and industry standards demand materials that deliver higher resistance in extreme environments.

Technological advances: Modern furnaces, reactors, and boilers are designed to run hotter and longer, requiring stronger, more stable materials.

Comparison with Other Alloys

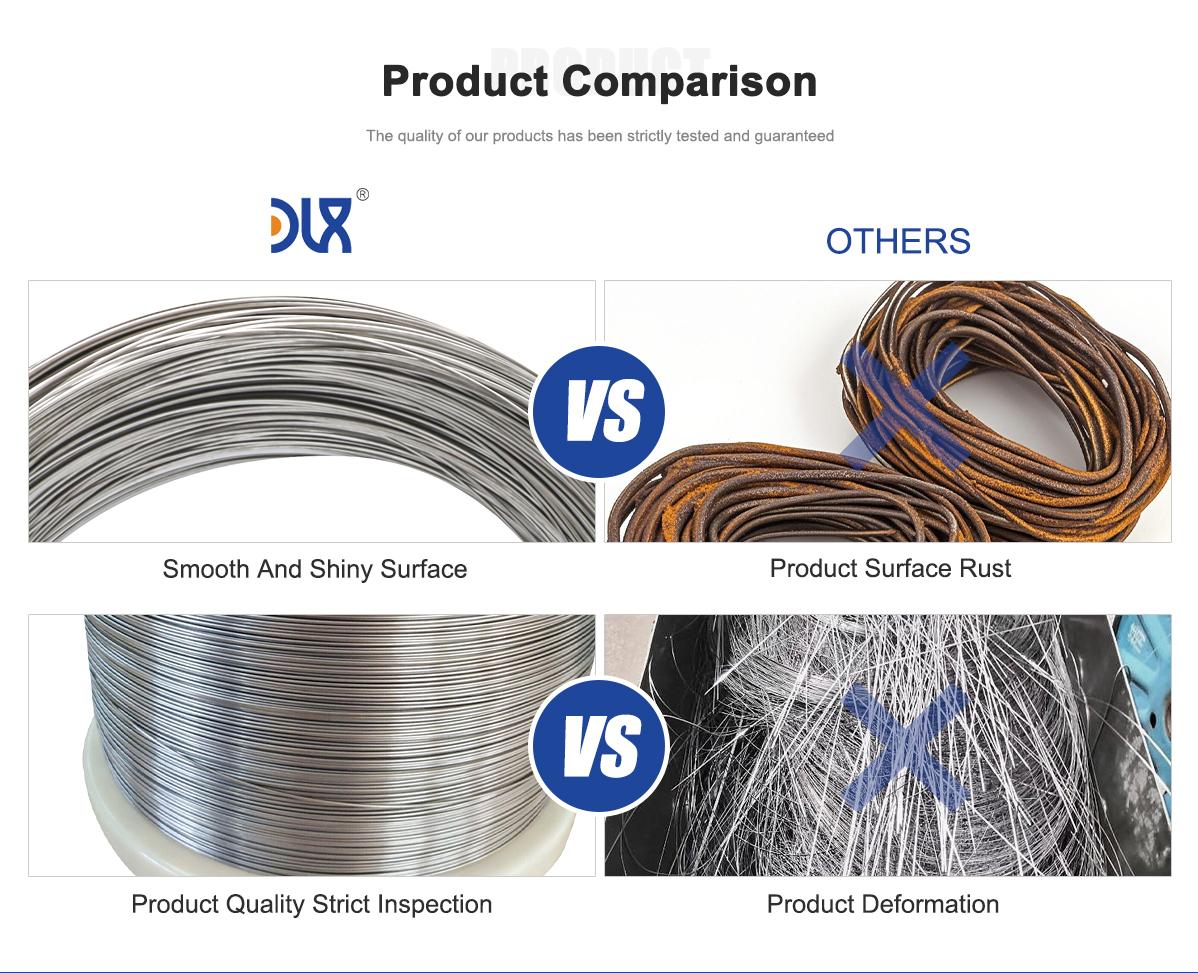

While stainless steels provide some resistance, they cannot match the high-temperature stability of Incoloy 800 wire. Duplex stainless steels may offer good corrosion resistance, but they fall short in creep strength and prolonged heat exposure.

Incoloy 800H and 800HT wires are close relatives of Incoloy 800. With adjusted carbon, aluminum, and titanium levels, they provide improved creep resistance for more severe applications. Inconel 600 wire also provides excellent high-temperature properties but can be more costly, making Incoloy 800 an attractive balance of performance and value.

Comparison Table: Incoloy 800 Wire vs Related Alloys

| Property | Incoloy 800 Wire | Incoloy 800H Wire | Incoloy 800HT Wire | Inconel 600 Wire |

|---|---|---|---|---|

| Base Composition | Ni-Fe-Cr | Ni-Fe-Cr (higher C, Al, Ti) | Ni-Fe-Cr (optimized Al + Ti) | Ni-Cr-Fe |

| Temperature Resistance | ~1100°C (2010°F) | ~1150°C (2100°F) | ~1150°C+ (enhanced creep resistance) | ~1150°C (2100°F) |

| Creep Resistance | Moderate | Improved | Excellent | Good |

| Oxidation Resistance | Excellent | Excellent | Excellent | Very Good |

| Corrosion Resistance | Good | Good | Good | Good |

| Strength at High Temp | Stable | Higher | Highest | High |

| Typical Applications | Petrochemical, power generation | Refinery heaters, petrochemical | Power plants, furnaces | Chemical processing, furnaces |

| Weldability | Good | Good | Good | Good |

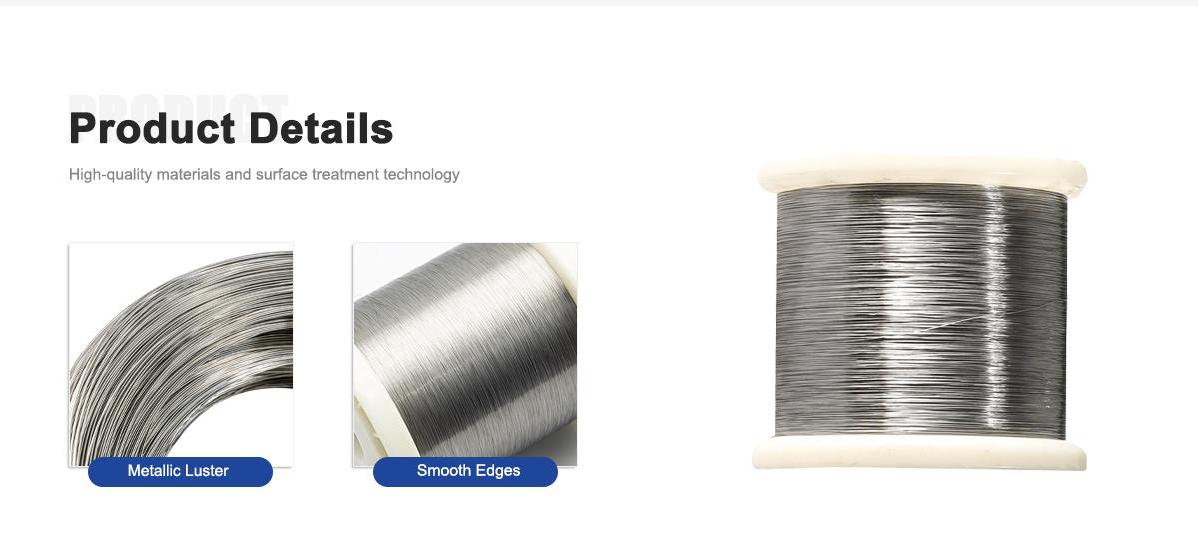

We manufacture Incoloy 800 wire in a wide range of diameters and formats, from fine wires for heating coils to thicker gauges for furnace supports. Available in coils, spools, or cut-to-length configurations, our products are tailored to meet project-specific needs. Surface finishes and packaging are designed for ease of handling and integration into industrial systems.

Our rigorous testing process includes tensile strength analysis, metallurgical evaluation, and non-destructive testing to guarantee compliance with international standards.

Our Advantages as a Supplier

Our company’s position as a leading supplier of Incoloy 800 wire is built on several strengths:

Extensive alloy expertise: Years of experience supplying high-performance materials to industries worldwide.

Quality assurance: Every batch undergoes comprehensive testing for mechanical and chemical properties.

Customization: We adapt wire sizes, forms, and finishes to client-specific requirements.

Global delivery: With a strong supply chain, we ensure on-time shipments to customers worldwide.

Technical guidance: We support clients in selecting the best alloy for their application, reducing risk and optimizing performance.

Sustainability commitment: By offering materials that last longer, we help reduce replacement cycles and overall environmental impact.

Future Outlook

As petrochemical production expands and global energy demand grows, the reliance on alloys like Incoloy 800 wire will only increase. Emerging industries such as renewable energy and advanced metallurgy will also require materials with proven high-temperature stability and corrosion resistance.

Our company is investing in new production technologies to increase efficiency and capacity. We are also expanding our research into alloy performance to better serve industries that continue to push the boundaries of high-temperature operations.

Incoloy 800 wire represents a balance of high-temperature strength, corrosion resistance, and long-term stability. From petrochemical processing to power generation, it has proven itself as a reliable solution in environments where failure is not an option.

By choosing our Incoloy 800 wire, clients gain not only a material but also the assurance of quality, expertise, and long-term support. We help industries reduce maintenance costs, extend equipment life, and achieve greater efficiency in the toughest operating conditions.

Strong, reliable, and built for high performance, Incoloy 800 wire is the foundation for industrial success in both petrochemical and power generation applications.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Incoloy 800 wire?

Nickel-iron-chromium alloy with balanced additions of carbon, aluminum, and titanium.What is the maximum service temperature for Incoloy 800 wire?

Approximately 1100°C (2010°F).Is Incoloy 800 wire resistant to oxidation?

Yes, it maintains excellent oxidation resistance at high temperatures.Can Incoloy 800 wire be used in power generation plants?

Yes, it is widely used in boilers, heat exchangers, and superheaters.Does Incoloy 800 wire resist carburization?

Yes, it provides strong resistance to carburization in furnace environments.Can Incoloy 800 wire be welded and fabricated?

Yes, it can be welded and formed using standard methods.What is the main advantage of Incoloy 800 wire in petrochemical applications?

Its stability and resistance to chloride stress cracking and sulfidation.Is Incoloy 800 wire available in customized sizes?