Corrosion-Resistant Incoloy 925 Wire for Harsh Chemical and Seawater Applications

Industrial operations in offshore and chemical environments face some of the harshest conditions imaginable. High chloride concentrations, seawater exposure, sour gas, and aggressive chemical media all combine to create an environment where conventional metals quickly corrode and fail. When equipment reliability is critical, operators turn to alloys specifically engineered to resist both chemical attack and mechanical stress. One such alloy is Incoloy 925 wire.

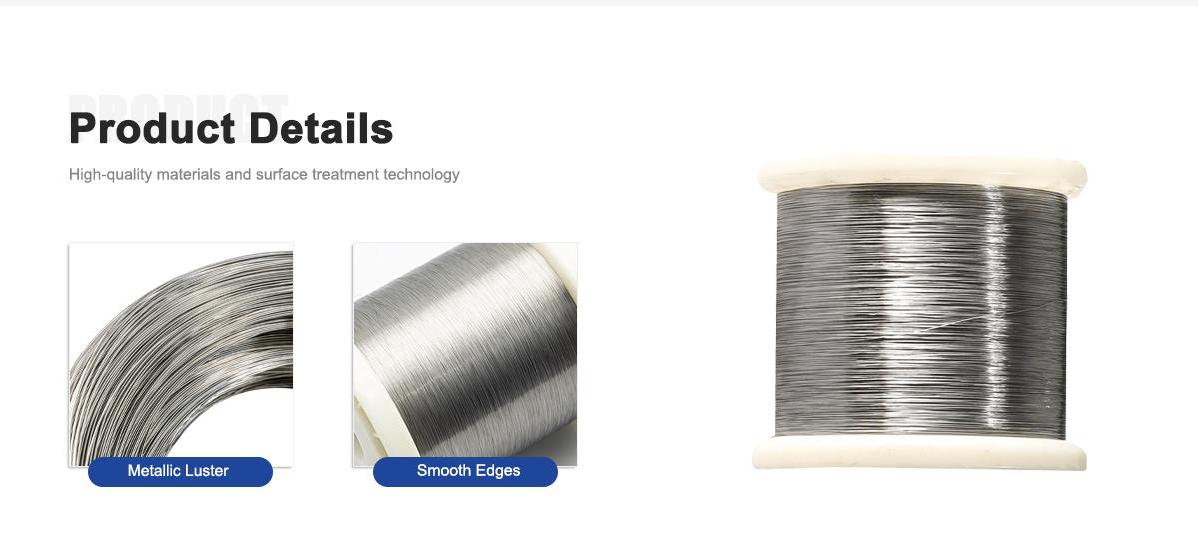

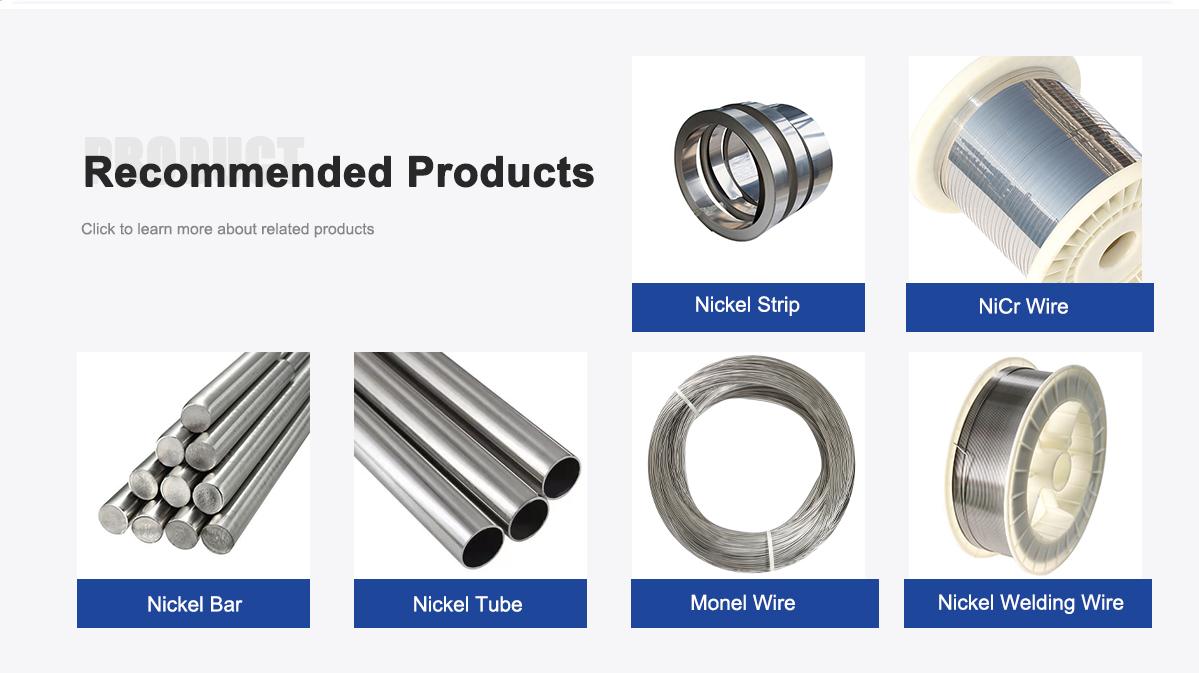

Incoloy 925 is a precipitation-hardened nickel-iron-chromium alloy with the added strength of molybdenum, copper, and titanium. It provides an outstanding balance of corrosion resistance and high strength, making it particularly suitable for demanding offshore, marine, and chemical applications. Our company supplies high-quality Incoloy 925 wire that is trusted in critical industries worldwide.

For more details, pls directly contact us.

The composition of Incoloy 925 is carefully designed to provide dual benefits: strength and corrosion resistance. Nickel contributes to general corrosion resistance, particularly in reducing environments. Chromium adds oxidation resistance, while molybdenum increases resistance to localized attack such as pitting and crevice corrosion. Copper enhances resistance in reducing acids, and titanium contributes to precipitation hardening for improved mechanical strength.

Key material advantages include:

Excellent resistance to chloride-induced stress corrosion cracking.

Outstanding seawater resistance, including in subsea and splash-zone environments.

High strength and toughness due to precipitation hardening.

Resistance to sour gas environments, making it suitable for oilfield applications.

Good fabricability, allowing it to be welded, formed, and machined.

This balance of properties makes Incoloy 925 wire a reliable choice for critical, long-life components.

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Marine engineering and offshore oil and gas are at the core of Incoloy 925 wire’s applications. Components exposed to seawater face the dual challenges of salt corrosion and mechanical stress. Ordinary stainless steels often fail prematurely under such conditions, leading to costly downtime and replacements.

Incoloy 925 wire excels in:

Subsea tubing and fasteners: Withstanding high chloride environments and mechanical stress.

Offshore oil production systems: Resistant to sour gas and seawater corrosion.

Valve and pump components: Maintaining reliability in seawater injection and chemical dosing systems.

Marine engineering fixtures: Used in fastening systems and reinforcement structures exposed to splash zones.

By maintaining both strength and corrosion resistance, Incoloy 925 wire ensures long service life even in the most aggressive offshore environments.

In addition to marine use, Incoloy 925 wire is also a vital material in chemical plants where equipment faces reducing acids, chlorides, and aggressive process chemicals.

Key uses include:

Chemical reactors: Supporting structures and components exposed to corrosive feeds.

Heat exchanger components: Providing durability in systems with corrosive process streams.

Separation and refining systems: Withstanding both chemical attack and operational stress.

Desalination plants: Delivering strength and resistance in brine-rich environments.

The reliability of Incoloy 925 wire reduces maintenance costs and improves uptime, which is essential for continuous chemical production.

Several global trends are pushing the adoption of Incoloy 925 wire:

Expansion of offshore oil and gas: Exploration in deep-water fields requires materials that can resist sour gas, seawater, and high mechanical stress.

Growth of marine infrastructure: Offshore wind and marine engineering projects rely on long-lasting materials.

Rising chemical production: Chemical plants are being designed to handle more aggressive feedstocks, requiring alloys with superior corrosion resistance.

Focus on sustainability: Longer-lasting materials like Incoloy 925 reduce waste, downtime, and replacement needs.

Stricter safety regulations: Industries must use proven alloys that resist failure in harsh environments.

These drivers ensure that Incoloy 925 wire will remain a material of choice across industries where reliability is paramount.

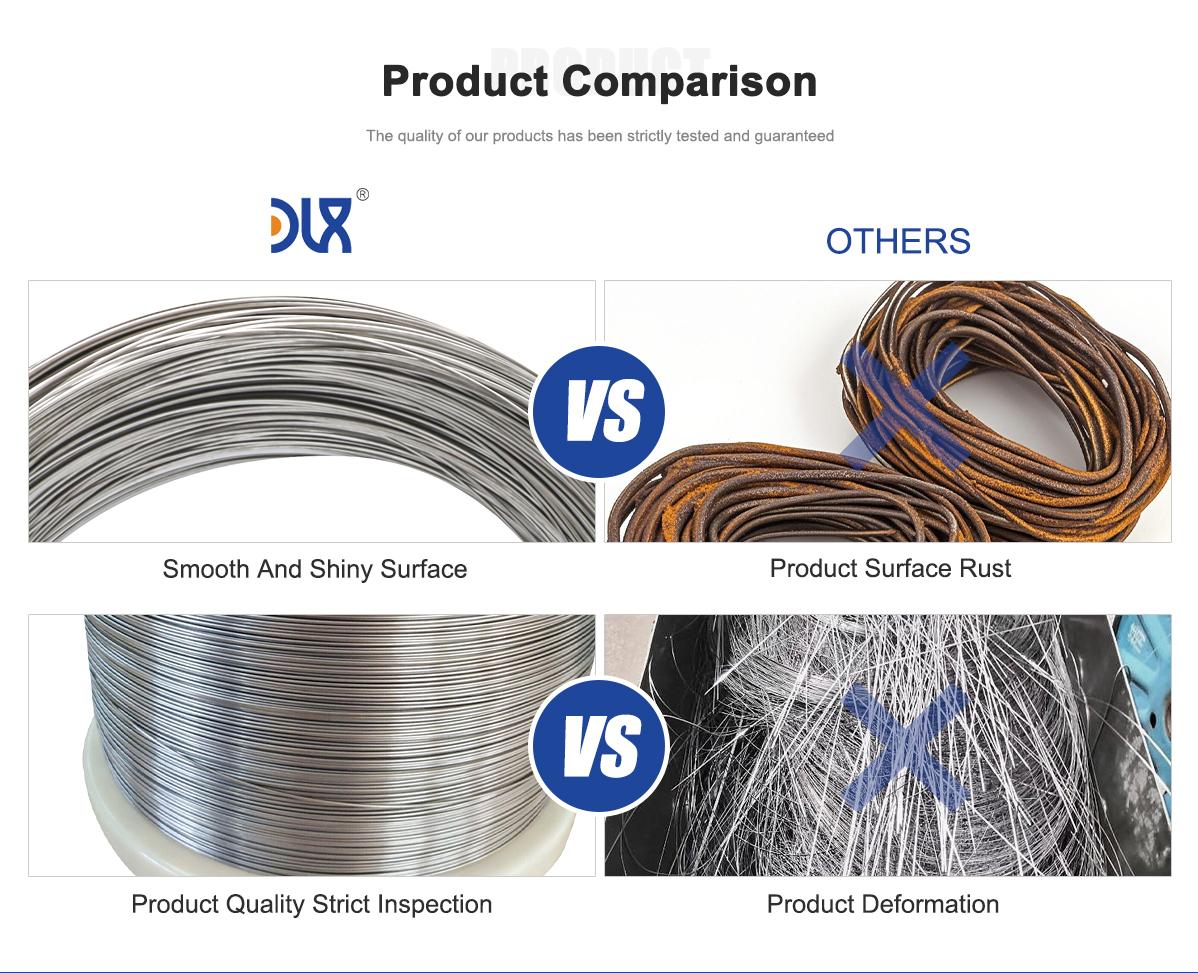

Compared to stainless steels, Incoloy 925 wire offers vastly superior resistance to stress corrosion cracking and sour gas environments. While stainless may suffice for mild applications, it cannot match the long-term reliability of Incoloy 925 in offshore or chemical systems.

When compared to high-temperature alloys such as Incoloy 800H T, Incoloy 925 is less focused on creep resistance but far stronger against chloride and seawater corrosion. This makes it complementary to other alloys in the Incoloy family, each serving specialized roles in different environments.

We understand that each project requires unique solutions. That is why our Incoloy 925 wire is available in a wide range of diameters, tempers, and finishes. Whether needed for fine fastening applications, reinforcement structures, or large-scale offshore systems, we deliver tailored solutions.

Our production process includes:

Precision alloying to maintain exact chemical composition.

Mechanical and corrosion testing to confirm performance.

Non-destructive evaluations for quality assurance.

Custom spooling and packaging to suit client requirements.

This flexibility ensures that customers receive material that integrates seamlessly into their systems.

Comparison Table: Incoloy 800HT Wire vs Incoloy 925 Wire

| Property | Incoloy 800HT Wire | Incoloy 925 Wire |

|---|---|---|

| Base Composition | Ni-Fe-Cr with Al + Ti balance | Ni-Fe-Cr with Mo, Cu, Ti |

| Primary Strength | Superior creep resistance | High strength + corrosion resistance |

| Temperature Resistance | Up to ~1150°C (2100°F) | Good high-temp stability, moderate range |

| Corrosion Resistance | Oxidation + carburization resistance | Seawater, sour gas, chloride resistance |

| Key Applications | Power plants, furnaces, petrochemicals | Offshore oil, gas, chemical processing |

| Stress Rupture Strength | Very high | High, with stress cracking resistance |

| Marine Suitability | Limited | Excellent |

| Industry Focus | Energy, petrochemical, high-temp systems | Offshore, subsea, chemical, marine |

Our strength lies not only in the materials we supply but also in the value-added services that ensure customer success.

Technical knowledge: We guide customers in selecting the right alloy for their specific environment.

Stringent quality control: Each batch undergoes thorough inspection and testing.

Global reach: Reliable logistics ensure on-time delivery to offshore and chemical hubs worldwide.

Customization: From dimensions to packaging, we provide tailored solutions.

Customer-first support: Dedicated assistance from inquiry to after-sales service.

This combination of product quality and customer care sets us apart in the alloy industry.

Future Outlook

The future of Incoloy 925 wire is bright, with global industries pushing into more aggressive and challenging environments. Offshore energy, desalination, and chemical production will all continue to require corrosion-resistant, high-strength materials.

We are expanding our capabilities to meet this demand with enhanced production facilities, innovative testing, and increased capacity for customized orders. Our goal is to remain at the forefront of alloy supply, delivering reliability in every strand of Incoloy 925 wire we produce.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the primary advantage of Incoloy 925 wire in chemical and seawater environments?

It combines high strength with excellent resistance to corrosion and stress cracking.Can Incoloy 925 wire be used in sour gas and offshore oil production systems?

Yes, it is specifically designed for these environments.What alloying elements give Incoloy 925 wire its properties?

Nickel, iron, chromium, molybdenum, copper, and titanium.Is Incoloy 925 wire suitable for downhole and subsea applications?

Yes, it is widely used in tubing, valves, and fastening components for these areas.How does Incoloy 925 wire perform under high stress and seawater exposure?

It maintains both strength and corrosion resistance in such conditions.Is welding and fabrication possible with Incoloy 925 wire?

Yes, it can be welded and formed using standard techniques.What industries benefit most from Incoloy 925 wire?

Oil and gas, marine engineering, chemical processing, and desalination.Can Incoloy 925 wire be supplied in customized sizes and finishes?

Yes, customization is available for specific project requirements.