Superior Creep-Resistant Incoloy 800HT Wire for High-Temperature Power Plants

High-temperature industries demand materials that can stand the test of time in extreme environments. In the world of power generation and petrochemicals, temperatures can soar well beyond 1000°C, placing enormous stress on equipment. Ordinary steels or low-grade alloys quickly lose their strength, deform under load, and oxidize into failure. That is where Incoloy 800 HT wire comes in.

As a high-performance nickel-iron-chromium alloy, Incoloy 800HT wire is engineered to deliver exceptional creep resistance, oxidation stability, and long-term structural integrity. Specifically optimized with controlled aluminum and titanium content, it offers superior high-temperature strength compared to standard Incoloy 800 or 800H. This makes it the material of choice for power plants, refineries, and industrial furnaces that demand reliable, long-lasting performance.

For more details, pls directly contact us.

Incoloy 800HT is part of the Incoloy 800 series, which is well-known for its balance of strength and corrosion resistance. What sets 800HT apart is its precise control of aluminum and titanium levels, ensuring maximum stability during extended service at elevated temperatures.

The alloy is characterized by:

-

Superior creep and rupture strength for long-term high-temperature service.

-

Resistance to oxidation and carburization, protecting against surface degradation.

-

Excellent structural stability under thermal cycling and prolonged stress.

-

Good corrosion resistance in both oxidizing and reducing environments.

-

Weldability and formability, enabling versatile manufacturing.

These characteristics make it indispensable for industries where consistent, reliable operation at extreme heat is critical.

Chemical Composition Requirement

|

Item |

800 |

800H |

800HT |

825 |

925 |

|

C |

≤0.1 |

0.05-0.1 |

0.06-0.1 |

≤0.05 |

≤0.03 |

|

Mn |

≤1.5 |

≤1.5 |

≤1.5 |

≤1 |

≤1 |

|

Fe |

rest |

rest |

rest |

rest |

rest |

|

P |

-- |

-- |

-- |

≤0.02 |

≤0.03 |

|

S |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.03 |

≤0.03 |

|

Si |

≤1 |

≤1 |

≤1 |

≤0.5 |

≤0.5 |

|

Cu |

≤0.75 |

≤0.75 |

≤0.75 |

1.5-3 |

1.5-3 |

|

Ni |

30-35 |

30-35 |

30-35 |

38-46 |

42-46 |

|

Al |

0.15-0.6 |

0.15-0.6 |

0.15-0.6 |

0.2-1 |

0.15-0.5 |

|

Ti |

0.15-0.6 |

0.15-0.6 |

0.15-0.6 |

0.6-1.2 |

1.9-2.4 |

|

Cr |

19-23 |

19-23 |

19-23 |

19.5-23.5 |

19.5-23.5 |

|

Mo |

-- |

-- |

-- |

2.5-3.5 |

2.5-3.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

|

Product Form |

Standard |

|

Rod, bar & Wire |

ASTM B805 |

|

Plate, sheet & strip |

ASTM B872 |

|

Seamless pipe and tube |

ASTM B983 |

|

Forging |

ASTM B637 |

For more details, pls directly contact us.

Power plants are among the most demanding users of high-performance alloys. Boilers, superheaters, reheaters, and steam piping systems all operate under sustained high stress at elevated temperatures. Materials must endure thermal expansion, high pressure, and corrosive gases without losing integrity.

Incoloy 800HT wire is widely applied in:

-

Boiler tube supports: Resisting sagging and creep deformation over long operating cycles.

-

Superheater elements: Maintaining stability while exposed to continuous high steam temperatures.

-

Reheater components: Withstanding stress under fluctuating load conditions.

-

Steam generation fixtures: Providing secure support for wire meshes, ties, and reinforcement parts.

With its excellent creep resistance, Incoloy 800HT wire ensures that power plants operate reliably, minimizing downtime and extending equipment service life.

Applications Beyond Power Plants

While power generation is a major user, Incoloy 800HT wire finds applications across multiple high-temperature industries:

-

Petrochemical processing: In reactors, heaters, and catalyst supports where high heat and corrosive gases coexist.

-

Refineries: In cracking units and reformers requiring wire supports and reinforcement structures.

-

Heat-treatment furnaces: For fixtures, trays, and heating elements that undergo repeated heating and cooling cycles.

-

Industrial gas turbines: As part of support structures exposed to thermal stress and oxidation.

The versatility of Incoloy 800HT wire ensures that it plays a crucial role in both energy production and advanced materials processing.

Industry Trends Driving Demand

Several trends are fueling the growing demand for Incoloy 800HT wire:

-

Rising global energy needs: Power plants are under pressure to operate at higher efficiency and output, requiring alloys with superior creep performance.

-

Shift toward high-temperature efficiency: New plant designs push materials closer to their limits, making advanced alloys essential.

-

Expansion of petrochemical capacity: More refineries and processing plants demand durable materials for reactors and heat exchangers.

-

Sustainability focus: Longer-lasting materials reduce waste, downtime, and energy losses, aligning with greener industrial goals.

-

Safety regulations: Industries increasingly demand alloys with proven stability to minimize catastrophic failures.

Incoloy 800HT wire directly addresses these challenges, combining longevity with superior high-temperature strength.

Comparison Table: Incoloy 800 vs 800H vs 800HT Wire

| Property | Incoloy 800 Wire | Incoloy 800H Wire | Incoloy 800HT Wire |

|---|---|---|---|

| Base Composition | Ni-Fe-Cr | Ni-Fe-Cr with higher C, Al, Ti | Ni-Fe-Cr with optimized Al + Ti balance |

| Service Temperature | Up to ~1100°C (2010°F) | Up to ~1150°C (2100°F) | Up to ~1150°C (enhanced stability) |

| Creep Strength | Moderate | High | Superior |

| Oxidation Resistance | Excellent | Excellent | Excellent |

| Carburization Resistance | Good | Very Good | Very Good |

| High-Temp Stability | Stable | Improved | Superior long-term stability |

| Typical Applications | Furnaces, petrochemical heaters | Industrial furnaces, reactors, exchangers | Power plants, advanced petrochemical units |

When comparing Incoloy 800HT to stainless steels, the advantage is clear. Stainless steels perform well in corrosive environments but cannot match the creep strength of Incoloy 800HT above 1000°C.

Compared with Incoloy 800 and 800H, the 800HT version represents the highest level of creep resistance and long-term stability in the series. This makes it uniquely suited for the most demanding applications, such as modern power plants and petrochemical units designed for efficiency at extreme heat.

Customization and Manufacturing

We supply Incoloy 800HT wire in a wide range of diameters and formats, ensuring compatibility with diverse applications. From fine wires for heating elements to larger gauges for furnace fixtures, customization is available to meet specific project requirements.

Our production process includes:

-

Chemical composition analysis to confirm precise alloy balance.

-

Mechanical testing for creep, rupture, and tensile properties.

-

Non-destructive inspections to guarantee integrity and consistency.

-

Custom packaging and spooling to suit operational needs.

This flexibility allows us to deliver wire solutions that are not only high-performing but also tailored to each customer’s application.

Our Company’s Advantage

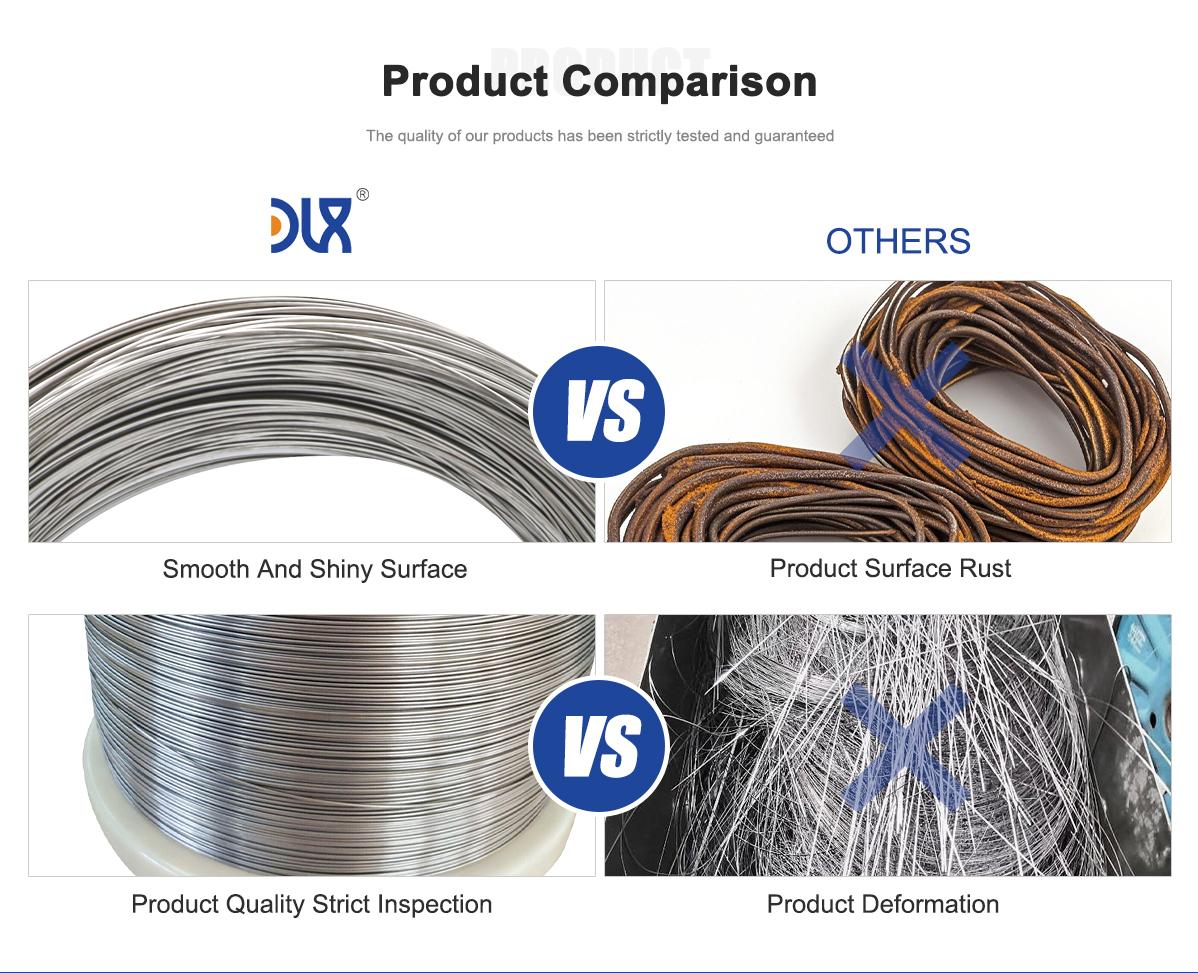

We differentiate ourselves not just by supplying Incoloy 800HT wire but by delivering comprehensive value:

-

Technical expertise: Deep understanding of high-performance alloys and their applications.

-

Quality assurance: Rigorous testing ensures every batch meets international standards.

-

Customization options: Wire dimensions, formats, and finishes tailored to client specifications.

-

Global logistics: Reliable supply chains ensuring on-time delivery worldwide.

-

Customer support: Guidance from material selection to application, reducing risks and optimizing performance.

-

Sustainability commitment: Long-life materials that support environmental and operational goals.

Our approach ensures that clients receive not just a product but a complete solution for their high-temperature challenges.

Future Outlook

The future of Incoloy 800HT wire is closely tied to the global demand for energy and advanced materials processing. As power plants and petrochemical facilities continue to push operational boundaries, the need for alloys with superior creep resistance will only grow.

We are investing in expanded production capacity, advanced testing methods, and ongoing alloy development to ensure our customers have access to reliable, cutting-edge materials. By anticipating industry shifts, we position ourselves as a long-term partner for clients across the globe.

Incoloy 800HT wire is one of the most capable materials for high-temperature service in power plants and other demanding industries. Its superior creep resistance, oxidation stability, and long-term structural integrity make it a cornerstone alloy for environments where failure is not an option.

Our role is to provide not only the highest quality Incoloy 800HT wire but also the expertise, customization, and support that ensure it performs flawlessly in each application. For industries committed to efficiency, safety, and sustainability, Incoloy 800HT wire remains the smart choice—strong, reliable, and built to withstand the toughest operating conditions.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What makes Incoloy 800HT wire different from standard Incoloy 800?

It has optimized aluminum and titanium content for superior creep resistance. -

What is the maximum service temperature of Incoloy 800HT wire?

Up to around 1150°C (2100°F) under continuous service. -

Is Incoloy 800HT wire suitable for power plant boilers and superheaters?

Yes, it is widely used in power generation systems exposed to high stress and temperature. -

Does Incoloy 800HT wire resist carburization and oxidation?

Yes, it maintains resistance even in aggressive, high-temperature environments. -

Can Incoloy 800HT wire be welded and fabricated easily?

Yes, it is weldable and can be formed with standard techniques. -

What industries benefit most from Incoloy 800HT wire?

Power generation, petrochemical, refining, and heat-treatment industries. -

How does Incoloy 800HT perform under long-term high stress?

It maintains superior creep and rupture strength over extended service periods. -

Is customized production of Incoloy 800HT wire available?

Yes, it can be supplied in tailored diameters, coils, and finishes.