High-Temperature Incoloy 800 Wire for Heat Treatment and Furnace Heating Elements

In high-temperature industrial environments, material reliability is everything. Processes such as heat treatment, petrochemical refining, and industrial furnace operations expose materials to extreme heat, oxidation, and carburization. In these conditions, conventional metals degrade quickly, leading to costly downtime and equipment replacement. Incoloy 800 wire was developed precisely to address these challenges, offering a balance of strength, stability, and resistance to high-temperature corrosion.

Our company specializes in the production and supply of high-performance alloys, and Incoloy 800 wire is a core part of our product portfolio. By supplying this wire to clients worldwide, we help ensure safe, efficient, and long-lasting performance in heat-intensive industrial systems.

For more details, pls directly contact us.

Incoloy 800 wire is a nickel-iron-chromium alloy engineered for superior performance in elevated temperatures. Its chemical composition typically includes 30–35% nickel, 19–23% chromium, and the balance iron, with small additions of carbon, aluminum, and titanium. This blend provides the ideal balance of mechanical strength and resistance to oxidation and carburization at elevated service temperatures.

What makes Incoloy 800 unique is its ability to remain stable when exposed to long-term high temperatures up to 1100°C (2010°F). Unlike many stainless steels, which can suffer from loss of ductility or structural integrity, Incoloy 800 retains its mechanical properties, ensuring that equipment continues to perform safely and reliably.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

The wire form of Incoloy 800 opens the door to a wide variety of high-temperature applications. Some of the most common include:

Furnace heating elements: Incoloy 800 wire is wound into coils or grids that serve as heating elements in electric furnaces, kilns, and industrial ovens. Its resistance to scaling and carburization ensures long service life even in continuous operation.

Heat treatment systems: In processes such as annealing, carburizing, and hardening, Incoloy 800 wire is used in fixtures, trays, and support grids. It maintains stability during repeated heating and cooling cycles.

Petrochemical processing: In refinery heaters, reformers, and cracking units, Incoloy 800 wire withstands corrosive atmospheres containing sulfur and carbon compounds.

Power generation: Boilers, superheaters, and heat exchangers in thermal power plants rely on materials like Incoloy 800 to perform under high heat and corrosive gases.

Industrial equipment reinforcement: Its strength and corrosion resistance make it suitable for use in mesh screens, binding wires, and other components exposed to heat and chemical attack.

Performance in High-Temperature Environments

One of the standout properties of Incoloy 800 wire is its resistance to carburization, oxidation, and scaling. In high-temperature furnaces where carbon-rich gases can cause embrittlement, Incoloy 800 wire provides a reliable defense. Similarly, in oxidizing atmospheres, the protective chromium oxide layer forms a shield against scale buildup.

This long-term stability reduces equipment maintenance frequency, lowers replacement costs, and ensures consistent production in industries where downtime is highly expensive.

The global demand for Incoloy 800 wire is closely tied to trends in energy, materials processing, and environmental compliance. Several key drivers are influencing adoption:

Expanding heat treatment industry: As more industries—automotive, aerospace, and toolmaking—require advanced heat-treated components, demand for reliable heating elements and fixtures is growing.

Petrochemical growth: Chemical processing plants worldwide are increasing production capacity, requiring materials that can handle high-temperature and corrosive environments.

Focus on efficiency and sustainability: Industries are under pressure to reduce energy waste and extend equipment lifespan. Incoloy 800 wire helps achieve these goals by providing reliable, long-term performance.

Shift toward high-performance alloys: As stainless steels reach their limits in aggressive environments, companies are increasingly adopting nickel-based alloys like Incoloy 800 for critical applications.

While Incoloy 800 wire is highly effective, other alloys such as Incoloy 800H, Incoloy 800HT , and Inconel 600 offer slightly different balances of properties. Incoloy 800H wire includes higher carbon content and additional titanium and aluminum, improving creep resistance. Incoloy 800HT takes this further, providing superior performance in extremely high-temperature applications. Inconel 600, another nickel-based alloy, offers excellent resistance but at a higher cost for certain applications.

In this spectrum, Incoloy 800 wire provides a cost-effective and reliable option for heat treatment and furnace heating, where both oxidation resistance and strength are critical.

Comparison Table: Incoloy 800 Wire vs Alternatives

| Property | Incoloy 800 Wire | Incoloy 800H Wire | Incoloy 800HT Wire | Inconel 600 Wire |

|---|---|---|---|---|

| Base Composition | Ni-Fe-Cr | Ni-Fe-Cr (higher C, Al, Ti) | Ni-Fe-Cr (optimized Al + Ti) | Ni-Cr-Fe |

| Temperature Resistance | ~1100°C (2010°F) | ~1150°C (2100°F) | ~1150°C+ (better creep resistance) | ~1150°C (2100°F) |

| Creep Resistance | Moderate | Improved | Excellent | Good |

| Oxidation Resistance | Excellent | Excellent | Excellent | Very Good |

| Corrosion Resistance | Good | Good | Good | Good |

| Strength at High Temp | Stable | Higher | Highest | High |

| Typical Applications | Heating elements, heat exchangers | Petrochemical, refinery heaters | Power generation, furnaces | Chemical processing, furnaces |

| Weldability | Good | Good | Good | Good |

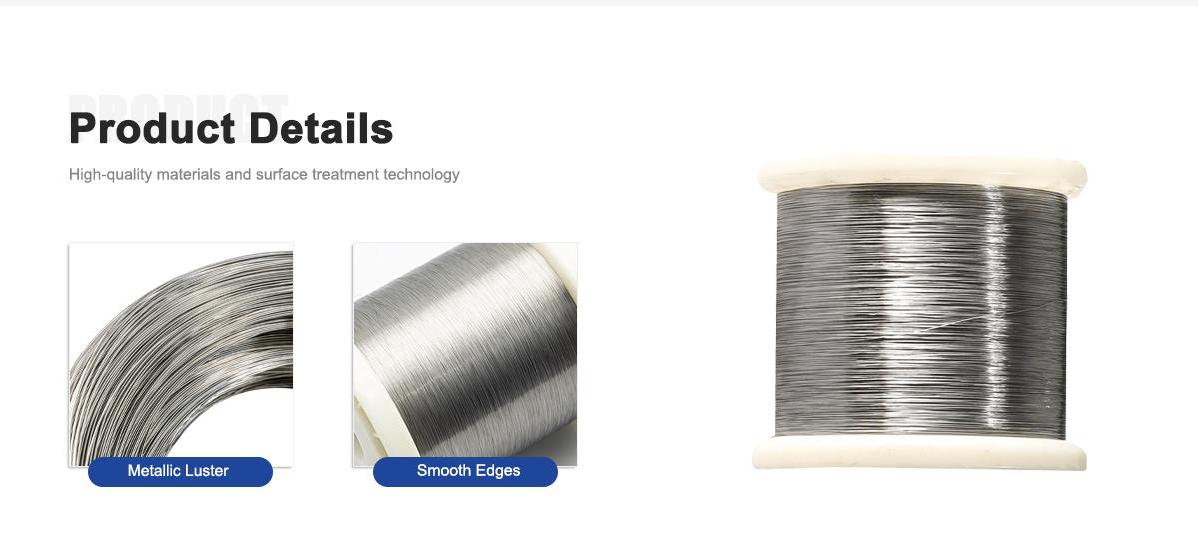

We supply Incoloy 800 wire in multiple forms—coils, spools, and cut-to-length pieces—depending on project needs. Diameters range from fine wires for delicate heating coils to thicker gauges for heavy-duty furnace supports. Surface finishes can be tailored, and we provide packaging designed for easy handling and deployment in industrial environments.

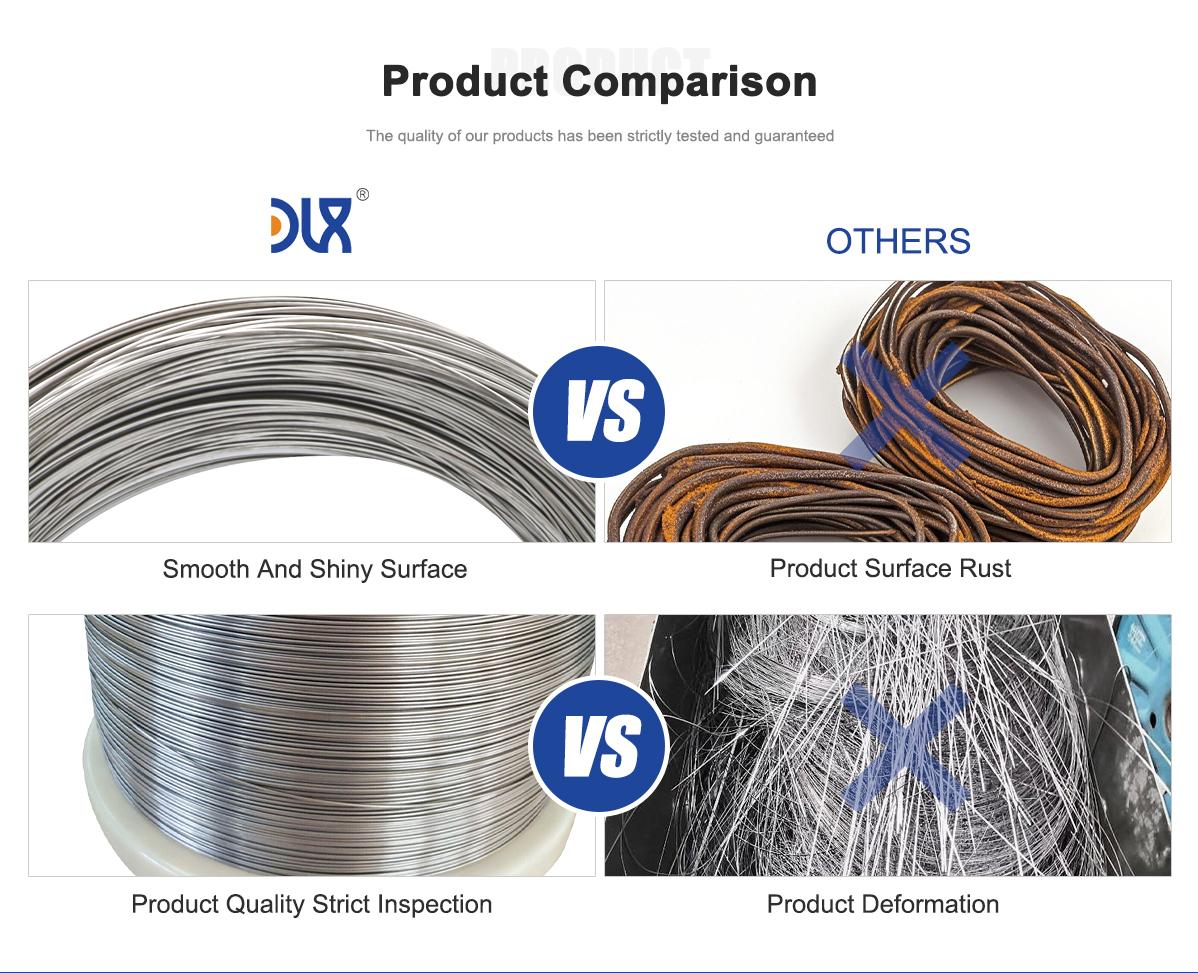

Our manufacturing process includes rigorous testing: tensile strength analysis, chemical composition verification, and surface inspection. These steps ensure every coil of wire meets stringent international standards.

Advantages of Partnering with Us

Our company stands out as a leading supplier of Incoloy 800 wire for several reasons:

Expertise in high-temperature alloys: With decades of experience, we understand the performance requirements of industries operating in extreme conditions.

Strict quality control: From raw materials to final product, our testing procedures ensure consistent, reliable results.

Custom solutions: We adapt wire dimensions, coil configurations, and surface treatments to suit each client’s application.

Global supply chain: Our established logistics network ensures on-time delivery to clients around the world.

Technical support: We don’t just deliver wire—we provide guidance on material selection, design optimization, and application integration.

Commitment to efficiency: By delivering wire with proven durability, we help clients lower operating costs and reduce environmental impact.

Future Outlook for Incoloy 800 Wire

The demand for Incoloy 800 wire is expected to continue growing as industries push into more demanding environments. With rising global energy needs, the expansion of chemical processing, and ongoing developments in metallurgy, materials like Incoloy 800 will remain essential.

At the same time, as industries emphasize sustainability and operational efficiency, the role of alloys that extend equipment lifespan will only become more important. Incoloy 800 wire, with its ability to provide stable performance over long operating cycles, aligns perfectly with these future needs.

We are expanding our production capabilities to meet rising demand and investing in advanced testing facilities to guarantee the highest quality standards. Our goal is to remain at the forefront of supplying alloys that enable industries to perform safely, efficiently, and sustainably.

Conclusion

Incoloy 800 wire offers a unique combination of strength, stability, and corrosion resistance that makes it indispensable in heat treatment, furnace heating, petrochemical, and power generation applications. By resisting carburization, oxidation, and scaling, it delivers long-lasting performance in environments where other alloys fail.

For clients, the choice of supplier is just as critical as the choice of material. Our expertise, commitment to quality, and ability to deliver customized solutions position us as a trusted partner for projects worldwide. With Incoloy 800 wire, we help industries achieve greater efficiency, reliability, and safety, even under the most demanding conditions.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the main composition of Incoloy 800 wire?

Nickel-iron-chromium alloy with balanced amounts of nickel and chromium.What industries commonly use Incoloy 800 wire?

Petrochemical, power generation, metallurgy, and heat treatment industries.What is the maximum service temperature for Incoloy 800 wire?

Approximately 1100°C (2010°F).Is Incoloy 800 wire resistant to oxidation and carburization?

Yes, it resists oxidation, carburization, and scaling in high-temperature service.Can Incoloy 800 wire be welded?

Yes, with standard welding techniques and proper filler materials.Does Incoloy 800 wire resist chloride stress corrosion cracking?

Yes, it offers resistance but performs best in high-temperature dry environments.What are the common forms of Incoloy 800 wire supply?

Coils, spools, and cut-to-length wires.Can Incoloy 800 wire be customized for specific projects?

Yes, it can be manufactured in custom diameters, lengths, and surface finishes.