Creep-Resistant Incoloy 800H Wire for Industrial Furnace and Chemical Applications

The success of modern industry relies on materials that can endure punishing conditions without losing strength or stability. Industrial furnaces, petrochemical units, and chemical processing plants all operate in environments that push metals to their breaking points. Ordinary steels quickly degrade, suffering from oxidation, creep, and carburization. For these critical applications, Incoloy 800 H wire has emerged as one of the most reliable choices. Its unique composition and engineered properties make it ideal for high-temperature service where creep resistance and long-term stability are essential.

Incoloy 800H is a nickel-iron-chromium alloy designed as an enhancement of Incoloy 800. The defining feature of the 800H grade is its higher carbon content and balanced additions of aluminum and titanium. These modifications significantly improve creep strength and stress rupture properties.

For more details, pls directly contact us.

-

Excellent creep resistance: It maintains mechanical strength under long-term high-temperature stress.

-

Oxidation and carburization resistance: Stable protective oxide scales prevent surface degradation.

-

Structural stability: It resists metallurgical changes that can weaken alloys during prolonged service.

-

Corrosion resistance: Good resistance in both oxidizing and reducing chemical environments.

These features make Incoloy 800H wire a trusted material for applications where both heat and corrosion create extreme operating challenges.

Chemical Composition Requirement

|

Item |

800 |

800H |

800HT |

825 |

925 |

|

C |

≤0.1 |

0.05-0.1 |

0.06-0.1 |

≤0.05 |

≤0.03 |

|

Mn |

≤1.5 |

≤1.5 |

≤1.5 |

≤1 |

≤1 |

|

Fe |

rest |

rest |

rest |

rest |

rest |

|

P |

-- |

-- |

-- |

≤0.02 |

≤0.03 |

|

S |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.03 |

≤0.03 |

|

Si |

≤1 |

≤1 |

≤1 |

≤0.5 |

≤0.5 |

|

Cu |

≤0.75 |

≤0.75 |

≤0.75 |

1.5-3 |

1.5-3 |

|

Ni |

30-35 |

30-35 |

30-35 |

38-46 |

42-46 |

|

Al |

0.15-0.6 |

0.15-0.6 |

0.15-0.6 |

0.2-1 |

0.15-0.5 |

|

Ti |

0.15-0.6 |

0.15-0.6 |

0.15-0.6 |

0.6-1.2 |

1.9-2.4 |

|

Cr |

19-23 |

19-23 |

19-23 |

19.5-23.5 |

19.5-23.5 |

|

Mo |

-- |

-- |

-- |

2.5-3.5 |

2.5-3.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

|

Product Form |

Standard |

|

Rod, bar & Wire |

ASTM B805 |

|

Plate, sheet & strip |

ASTM B872 |

|

Seamless pipe and tube |

ASTM B983 |

|

Forging |

ASTM B637 |

For more details, pls directly contact us.

Industrial furnaces are central to steel production, ceramics, glass manufacturing, and thermal processing. They operate at sustained high temperatures where equipment is exposed to oxidation, scaling, and carburization. Incoloy 800H wire is widely used for:

-

Heating elements: High creep resistance ensures elements retain shape and function under stress.

-

Support structures and fixtures: Wire meshes, grids, and frames resist sagging and distortion.

-

Carburizing furnaces: The alloy’s resistance to carbon absorption makes it ideal for furnace environments rich in carbon monoxide.

By choosing Incoloy 800H wire, furnace operators reduce downtime, extend equipment life, and maintain consistent performance in demanding thermal cycles.

The chemical industry presents some of the most challenging operating conditions for alloys. Equipment must withstand corrosive media and maintain strength under high pressures and temperatures. Incoloy 800H wire is employed in:

-

Heat exchangers: Withstands hot, corrosive fluids in petrochemical and refining plants.

-

Reactor internals: Provides support and reinforcement where chemical reactions occur at elevated temperatures.

-

Catalyst supports: Wire structures offer durability and corrosion resistance for long-term catalyst performance.

The alloy’s ability to perform reliably in both oxidizing and reducing conditions makes it invaluable for chemical industries handling hydrocarbons, acids, and other aggressive chemicals.

The demand for Incoloy 800H wire continues to rise, shaped by global industry trends:

-

Growth in chemical and petrochemical production: Expanding capacity requires materials that can sustain continuous, high-temperature operation.

-

Increased energy demand: Power and thermal processing plants push for higher efficiency, needing alloys with superior creep properties.

-

Tighter environmental and safety regulations: Industries demand materials that last longer, reduce failure risks, and cut maintenance costs.

-

High-temperature advancements: New-generation furnaces and reactors are designed for hotter conditions, requiring stronger, more stable alloys.

-

Shift toward sustainability: Long-life alloys reduce material waste, contributing to greener industrial operations.

These trends ensure that alloys like Incoloy 800H wire will remain vital to global heavy industries for decades to come.

Comparison Table: Incoloy 800 vs 800H vs 800HT Wire

| Property | Incoloy 800 Wire | Incoloy 800H Wire | Incoloy 800HT Wire |

|---|---|---|---|

| Base Composition | Ni-Fe-Cr | Ni-Fe-Cr with higher C, Al, Ti | Ni-Fe-Cr optimized with higher Al + Ti |

| Service Temperature | Up to ~1100°C (2010°F) | Up to ~1150°C (2100°F) | Up to ~1150°C+ (enhanced creep resistance) |

| Creep Strength | Moderate | Higher | Highest |

| Oxidation Resistance | Excellent | Excellent | Excellent |

| Carburization Resistance | Good | Very Good | Very Good |

| High-Temp Stability | Stable | Improved | Superior |

| Typical Applications | Power generation, petrochemical furnaces | Industrial furnaces, chemical equipment | Power plants, advanced petrochemical units |

When comparing Incoloy 800H wire to stainless steels, the advantages are clear. While stainless steels provide corrosion resistance, they cannot maintain creep strength beyond 1000°C. Incoloy 800H, by contrast, retains strength and stability up to 1150°C.

Compared with Incoloy 800, the 800H version offers improved creep resistance, making it better suited for long-term exposure in high-temperature furnaces and chemical systems. Incoloy 800HT takes these improvements further with optimized aluminum and titanium levels, offering the highest creep strength of the series.

Incoloy 800H thus represents the balanced middle ground—providing excellent strength, stability, and cost-effectiveness for a wide range of applications.

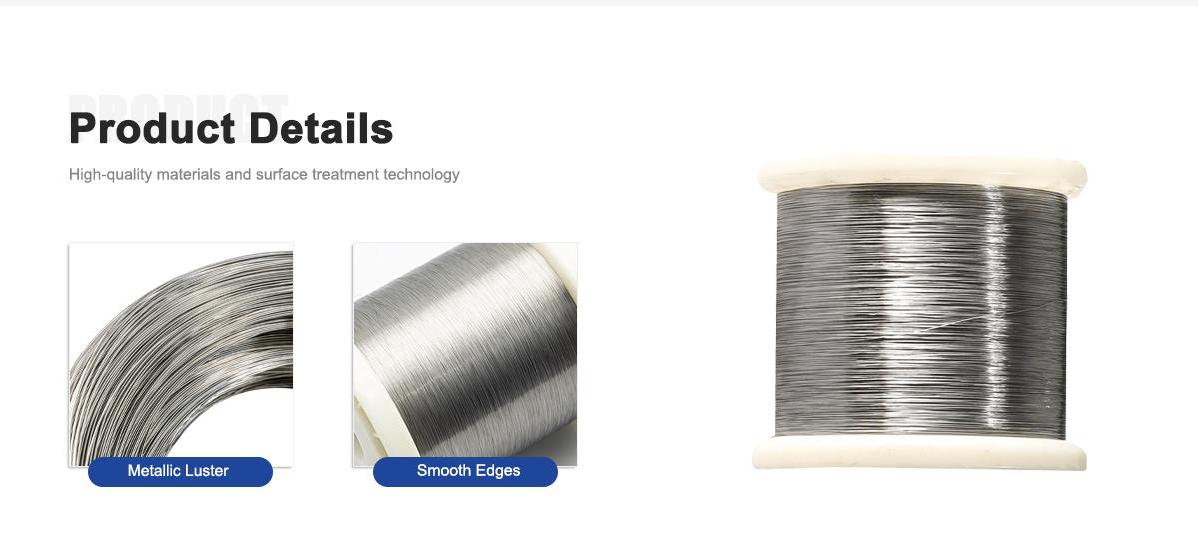

Manufacturing and Customization

We manufacture Incoloy 800H wire in a wide range of sizes and formats. Whether fine wire for furnace elements or larger diameters for support grids, we provide products tailored to customer needs. Available in coils, spools, or straight-cut lengths, the wire can be adapted to specific industrial requirements.

Each production batch undergoes:

-

Chemical composition analysis

-

Mechanical testing for creep and rupture properties

-

Non-destructive evaluations to ensure integrity

We also offer customized coil configurations, packaging, and surface finishes to suit project-specific requirements.

Our Advantages as a Supplier

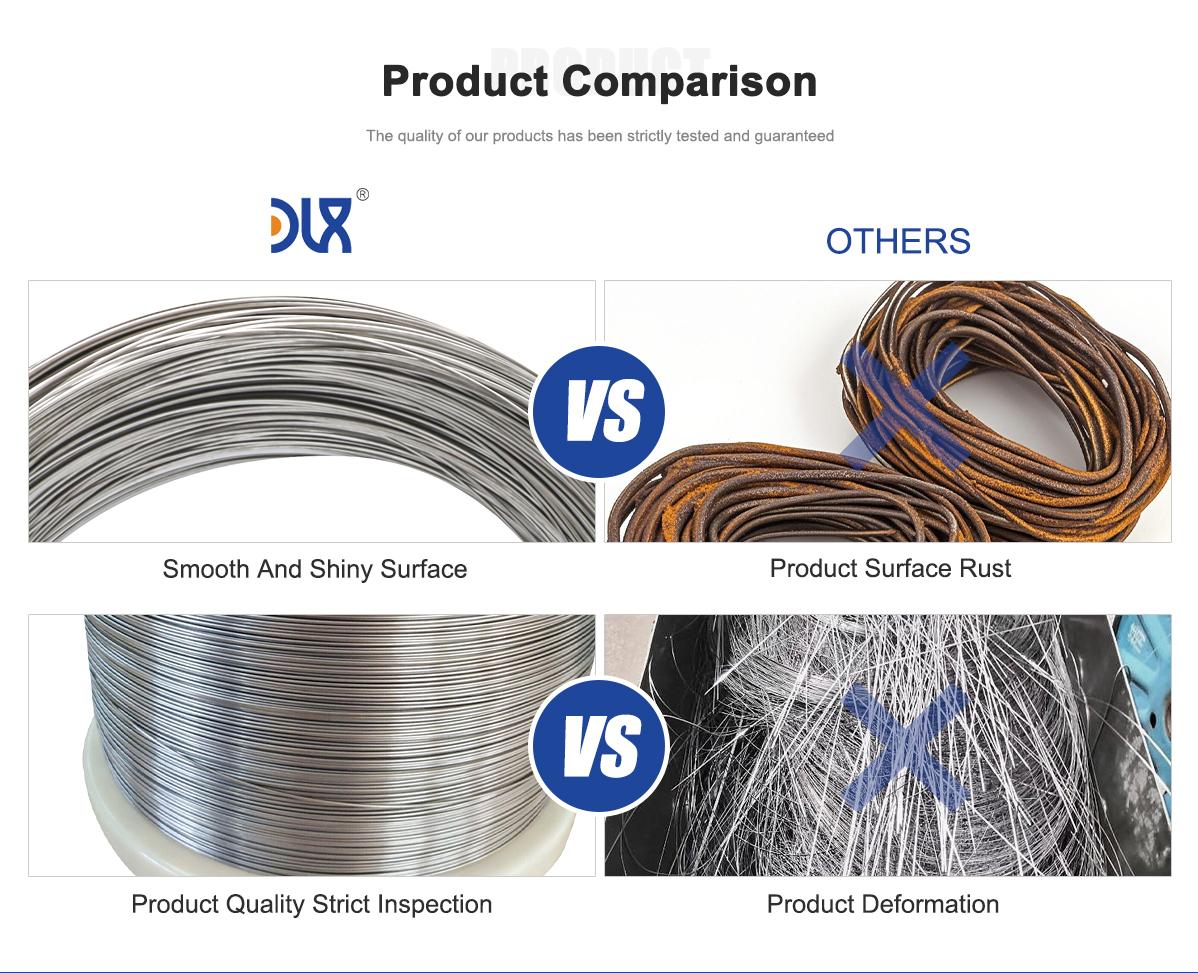

Our strength lies not only in supplying Incoloy 800H wire but also in delivering value-added solutions. We emphasize:

-

Expertise: Years of experience in supplying high-performance alloys for demanding industries.

-

Quality control: Stringent testing guarantees compliance with international standards.

-

Customization: Wire dimensions, finishes, and packaging tailored to client specifications.

-

Reliable logistics: Global shipping network ensuring on-time delivery.

-

Technical support: Skilled engineers guide clients in selecting and applying the right alloys.

-

Sustainability: Long-lasting materials that reduce replacement cycles and environmental impact.

By combining material excellence with technical and logistical support, we provide customers with solutions that go beyond simply supplying wire.

Future Outlook

As industries evolve, the need for creep-resistant alloys like Incoloy 800H wire will continue to expand. The petrochemical and chemical industries are scaling up production, power plants are moving toward higher efficiency, and industrial furnaces are being designed for more extreme service.

Our company is investing in advanced production capabilities and ongoing research to improve material performance and supply reliability. This ensures our clients benefit from continuous innovation and secure long-term access to high-quality Incoloy 800H wire.

Conclusion

Incoloy 800H wire is engineered to withstand the dual challenges of high temperatures and aggressive chemical environments. With its superior creep resistance, oxidation resistance, and long-term stability, it is indispensable for industrial furnaces and chemical processing systems.

Our commitment is to deliver more than just a material—we provide a partnership built on reliability, technical knowledge, and global supply capability. By choosing our Incoloy 800H wire, customers secure a durable solution that enhances efficiency, minimizes downtime, and supports safe, sustainable operations.

Strong, dependable, and engineered for the harshest conditions, Incoloy 800H wire remains the material of choice for industries where performance cannot be compromised.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the main advantage of Incoloy 800H wire in high-temperature applications?

It provides excellent creep and rupture resistance at elevated temperatures. -

What is the maximum service temperature of Incoloy 800H wire?

Approximately 1150°C (2100°F). -

Can Incoloy 800H wire resist carburization and oxidation?

Yes, it offers strong resistance to both in aggressive environments. -

Is Incoloy 800H wire suitable for industrial furnaces?

Yes, it is widely used in furnace heating elements, supports, and structural components. -

How does Incoloy 800H differ from standard Incoloy 800?

It contains higher carbon and stabilizers for improved high-temperature strength. -

Can Incoloy 800H wire be used in chemical processing applications?

Yes, it performs well in reactors, heat exchangers, and equipment exposed to corrosive chemicals. -

Is Incoloy 800H wire weldable and formable?

Yes, it can be welded and fabricated with standard techniques. -

Is customized production of Incoloy 800H wire available?

Yes, it can be manufactured in various diameters, coil forms, and finishes.