Durable Incoloy 800H Wire for Thermal Processing and Heat Exchanger Systems

In high-temperature industries, where performance, durability, and safety are non-negotiable, the choice of materials defines success. Thermal processing plants, petrochemical refineries, and heat exchanger systems operate under extreme stress, and only the most reliable alloys can deliver the strength and stability required for continuous operation. Incoloy 800H wire has established itself as one of the leading solutions in this demanding space, providing a balance of corrosion resistance, oxidation resistance, and superior high-temperature strength.

As a specialized manufacturer and supplier, we provide Incoloy 800H wire to global industries that demand exceptional performance in aggressive environments. Our expertise and dedication to quality make us a trusted partner for companies seeking long-term solutions in thermal processing and heat exchanger systems.

Incoloy 800H is a nickel-iron-chromium alloy, developed as an enhancement of standard Incoloy 800. The primary difference lies in its increased carbon content and carefully balanced additions of aluminum and titanium. These modifications boost its creep and rupture strength, enabling it to maintain stability at higher service temperatures.

The alloy’s strength lies in its ability to resist oxidation, carburization, and sulfidation while retaining mechanical integrity. This makes Incoloy 800H wire especially suitable for components that must withstand long-term exposure to elevated temperatures in both oxidizing and reducing atmospheres.

For more details, pls directly contact us.

Thermal processing facilities rely on equipment that can endure years of constant exposure to heat. Incoloy 800H wire is a core material in these systems, used in:

Furnace heating elements: Its resistance to oxidation ensures durability in continuous heating cycles.

Support grids and fixtures: Strong creep resistance allows structural integrity over long operating periods.

Carburizing and annealing equipment: With its high resistance to carburization, it is ideal for heat treatment systems.

By resisting deformation and surface degradation at extreme temperatures, Incoloy 800H wire helps extend furnace life and reduce downtime.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Heat exchangers operate under conditions where both heat and corrosive media are present, requiring alloys with dual resistance. Incoloy 800H wire is frequently used as reinforcement, support, or fabrication material in heat exchanger systems.

Petrochemical exchangers: Handles corrosive hydrocarbons and gases without losing stability.

Power generation exchangers: Performs reliably in steam cycles and high-pressure environments.

Industrial heating systems: Provides long-lasting support where heat transfer efficiency is critical.

The durability of Incoloy 800H wire ensures consistent heat transfer, reducing the risks of failures that could lead to costly shutdowns.

Industry Trends Driving Incoloy 800H Demand

Several global trends are fueling growth in the adoption of Incoloy 800H wire:

Growth in petrochemical capacity: Expanding refining and chemical plants require alloys with long service lives.

Power generation upgrades: Modern plants are pushing for higher efficiency, demanding materials with superior creep strength.

Sustainability initiatives: Industries are seeking alloys that reduce maintenance cycles, lowering overall waste and resource consumption.

Tighter safety regulations: The need for reliable, certified materials in thermal processing is at an all-time high.

Shift toward high-temperature processing: Advanced furnaces and reactors operate hotter, requiring alloys that do not lose stability.

When compared with stainless steels, Incoloy 800H wire stands out due to its superior creep and rupture strength at high temperatures. Stainless steels may offer corrosion resistance but fail to provide long-term stability above 1000°C.

Compared with Incoloy 800, the 800H variant offers improved mechanical strength, making it better suited for prolonged high-temperature service. Incoloy 800HT further enhances creep resistance but is often reserved for the most extreme applications. For many thermal processing and heat exchanger systems, Incoloy 800H wire strikes the perfect balance between performance and cost.

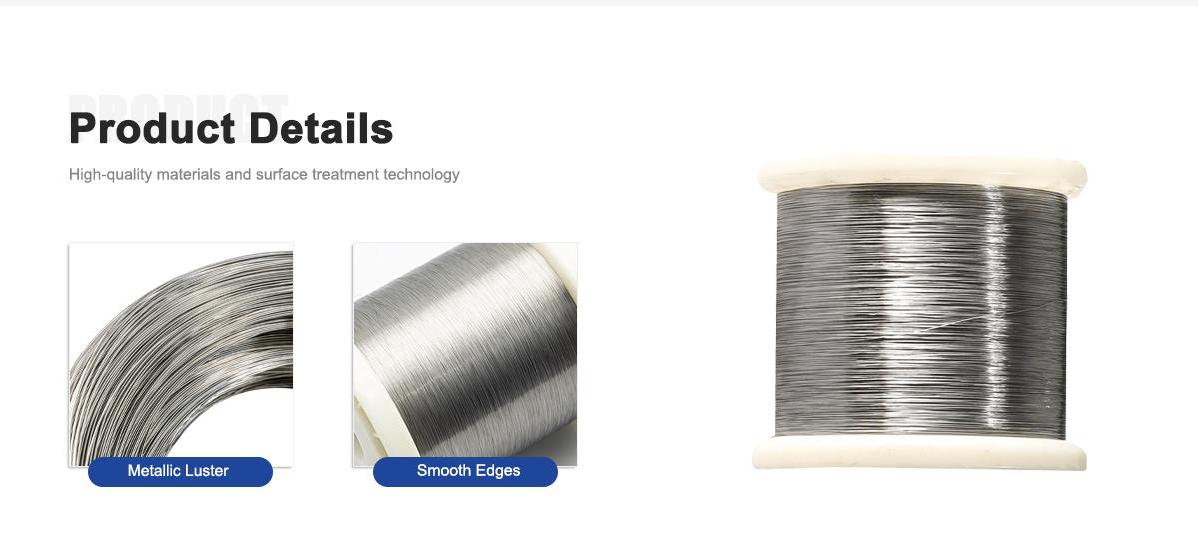

We manufacture Incoloy 800H wire in a variety of diameters and formats, ranging from fine wires used in heating elements to thicker gauges for structural reinforcement. Available in coils, spools, or straight-cut lengths, our products are tailored to meet diverse industry requirements.

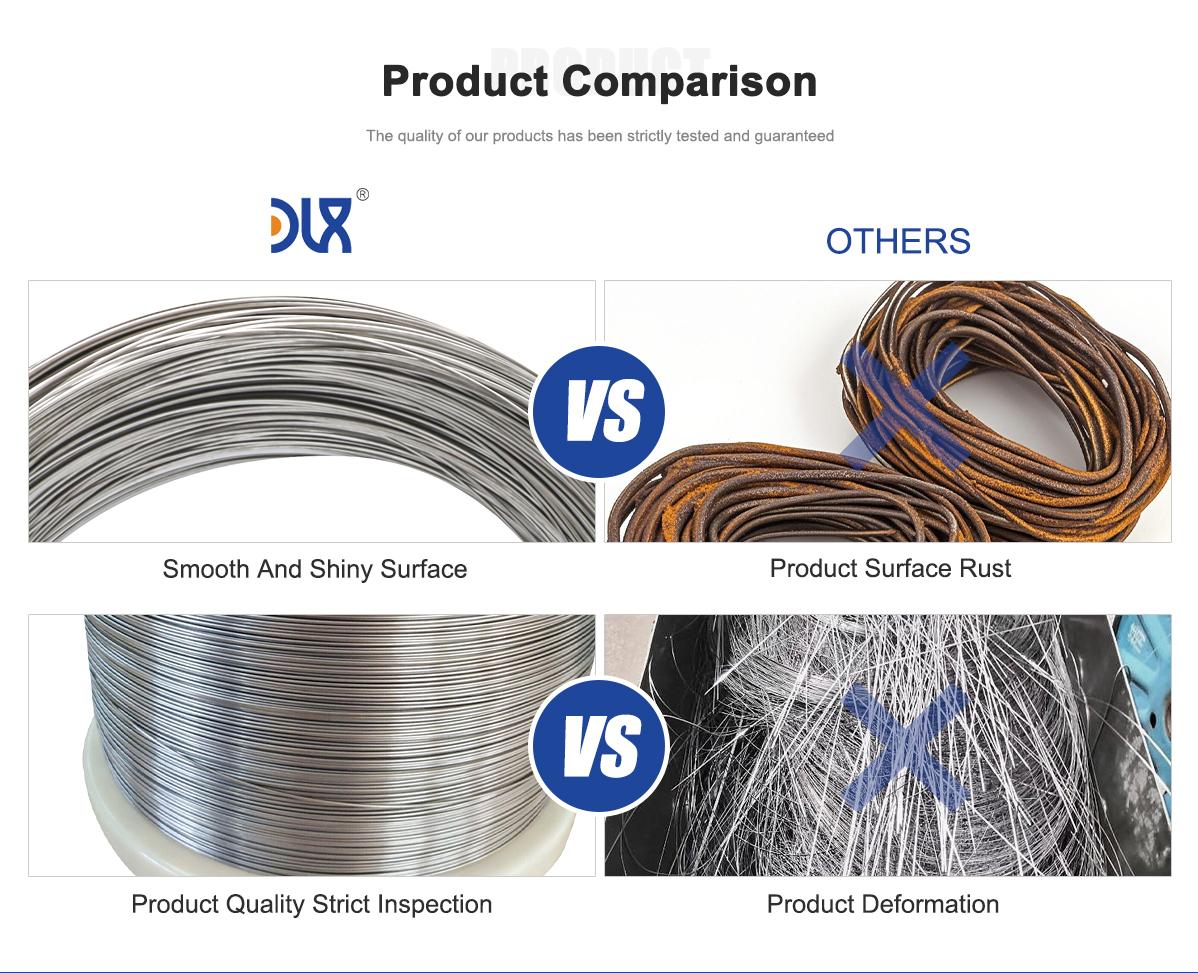

Surface finishes, packaging, and coil configurations can be customized according to client specifications. Each production batch undergoes strict chemical analysis, mechanical testing, and non-destructive evaluation to ensure compliance with international standards.

Comparison Table: Incoloy 800 vs 800H vs 800HT Wire

| Property | Incoloy 800 Wire | Incoloy 800H Wire | Incoloy 800HT Wire |

|---|---|---|---|

| Base Composition | Ni-Fe-Cr | Ni-Fe-Cr with higher C, Al, Ti | Ni-Fe-Cr optimized with higher Al + Ti |

| Service Temperature | Up to ~1100°C (2010°F) | Up to ~1150°C (2100°F) | Up to ~1150°C+ (enhanced creep resistance) |

| Creep Strength | Moderate | Higher | Highest |

| Oxidation Resistance | Excellent | Excellent | Excellent |

| Carburization Resistance | Good | Very Good | Very Good |

| High-Temp Stability | Stable | Improved | Superior |

| Typical Applications | Furnaces, power generation, petrochemical | Thermal processing, heat exchangers | Power plants, advanced petrochemical units |

What sets us apart in the supply of Incoloy 800H wire is not just the material itself but the added value we bring:

Proven expertise: Extensive experience supplying alloys for critical thermal and petrochemical applications.

Quality assurance: Comprehensive testing ensures each delivery meets stringent mechanical and chemical requirements.

Customization flexibility: Wire dimensions, finishes, and coil types adapted to client-specific projects.

Reliable logistics: Global distribution capabilities that guarantee timely deliveries.

Technical support: Dedicated specialists assist customers in selecting and implementing the right alloy for their systems.

Sustainability focus: Durable materials reduce replacement cycles, cutting down on waste and costs.

The role of Incoloy 800H wire will only grow as industries worldwide continue to demand stronger, more reliable materials for high-temperature operations. Petrochemical plants are scaling up capacity, while power generation facilities are moving toward efficiency upgrades. At the same time, global regulations are tightening standards for material safety and durability.

Our company is actively expanding production capabilities, investing in advanced equipment, and conducting research to refine alloy performance. By staying ahead of industry trends, we ensure our clients always have access to the most reliable solutions for their demanding applications.

Conclusion

Incoloy 800H wire represents durability, strength, and stability for industries where extreme conditions are the norm. From thermal processing furnaces to large-scale heat exchangers, its ability to withstand oxidation, carburization, and high-temperature creep makes it an indispensable choice.

Our commitment is to deliver more than just material. We provide assurance, technical expertise, and long-term partnership to ensure clients get the most from their investments. By choosing our Incoloy 800H wire, customers gain the durability their operations demand and the reliability their industries require.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Incoloy 800H wire?

Nickel-iron-chromium alloy with increased carbon, aluminum, and titanium.What is the service temperature range of Incoloy 800H wire?

Up to approximately 1150°C (2100°F).Is Incoloy 800H wire resistant to oxidation and carburization?

Yes, it offers strong resistance to both in high-temperature environments.Can Incoloy 800H wire be used in heat exchangers?

Yes, it is commonly used in heat exchanger tubing and reinforcement.What differentiates Incoloy 800H from standard Incoloy 800?

It has higher creep and rupture strength due to adjusted carbon and stabilizers.Can Incoloy 800H wire be welded easily?

Yes, it can be welded using standard techniques with compatible filler metals.Does Incoloy 800H wire perform well in petrochemical processes?

Yes, it is widely used in thermal processing and reforming units.Is Incoloy 800H wire available in custom diameters?

Yes, it can be manufactured in customized sizes, coils, and surface finishes.