Incoloy 800HT Wire for Stable Performance in Petrochemical and Refining Systems

In the world of high-performance alloys, our Incoloy 800HT wire stands out as a reliable solution for stable performance in petrochemical and refining systems. We've engineered this wire to meet the toughest demands of industries where heat, corrosion, and stress are everyday challenges. Let's dive into what makes our Incoloy 800HT wire a go-to choice, explore the broader industry landscape, and see how it fits into real-world applications. We'll also touch on how our approach gives us an edge in delivering top-notch products without naming any competitors.

First off, our Incoloy 800HT wire is built from a nickel-iron-chromium base, with precise additions of aluminum, titanium, and carbon. This composition isn't random—it's optimized for environments where temperatures soar above 700°C. The nickel content, around 30-35%, provides that solid foundation for corrosion resistance, while chromium at 19-23% forms a protective oxide layer that shields against oxidation and carburization. Iron makes up the balance, ensuring cost-effectiveness without skimping on strength. What sets our version apart is the tight control on aluminum and titanium levels (0.85-1.20% combined), which boosts creep resistance and long-term stability. We heat-treat it to lock in a face-centered cubic structure, meaning it stays tough even after thousands of hours in harsh conditions. In petrochemical setups, this translates to fewer breakdowns and more uptime.

For more details, pls directly contact us.

Speaking of the industry, the petrochemical and refining sectors are evolving fast. With global energy demands rising, refineries are pushing for higher efficiency and lower emissions. Trends show a shift toward sustainable practices, like using biofuels and hydrogen production, which require materials that can handle aggressive corrosives and extreme heat. According to recent market analyses, the high-temperature alloy market is growing at about 5-7% annually, driven by expansions in Asia-Pacific and the Middle East. Refineries are upgrading to handle heavier crudes, which means more sulfur and acids in the mix—exactly where our Incoloy 800HT wire shines. We're seeing more focus on predictive maintenance too, with IoT sensors monitoring equipment, but the core remains durable materials like ours to prevent failures. In refining, the push for net-zero goals is leading to innovations in carbon capture, where our wire's stability in high-pressure, high-heat systems is crucial. Overall, the trend is toward alloys that last longer, reduce downtime, and support greener operations.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Now, let's talk applications. In petrochemical plants, our Incoloy 800HT wire is perfect for reformer tubing in catalytic reforming units. These tubes endure constant heating and cooling cycles while exposed to hydrocarbons that could cause carburization. Our wire's design prevents that, ensuring the tubes don't crack or weaken over time. In ethylene pyrolysis furnaces, where temperatures hit 1100°C, it maintains integrity, helping produce essential chemicals like plastics and solvents. For refining systems, think flare tips and bellows—these components deal with combustion gases and thermal expansion. Our wire resists nitridation and sulfur attacks, common in sour gas environments, keeping operations safe and efficient. Offshore platforms use it in heat exchangers and process piping, where saltwater corrosion is a threat, but our alloy's aqueous resistance holds up. Even in chemical processing, like vinyl chloride cracking, it provides the strength needed for high-stress fixtures. We've supplied it for retorts and carburizing equipment too, where its low nickel content avoids embrittlement.

Comparison Parameters Table

| Parameter | Incoloy 800 | Incoloy 800H | Incoloy 800HT |

|---|---|---|---|

| Carbon Content (%) | 0.10 max | 0.05-0.10 | 0.06-0.10 |

| Al + Ti Content (%) | 0.15-0.60 | 0.15-0.60 | 0.85-1.20 |

| Creep Strength | Standard | Higher than 800 | Highest, with restricted chemistry |

| Max Service Temperature (°C/°F) | 870/1600 | 925/1700 | 1100/2010 |

| Tensile Strength (MPa/ksi at RT) | 520/75 | 520/75 | 520/75 |

| Yield Strength (MPa/ksi at RT) | 205/30 | 205/30 | 205/30 |

| Oxidation Resistance | Good | Excellent | Superior in high-temp atmospheres |

| Applications Focus | General high-temp | Petrochemical with creep | Refining with thermal stability |

| Corrosion in Aqueous Media | Resistant | Highly resistant | Excellent in nitric acid |

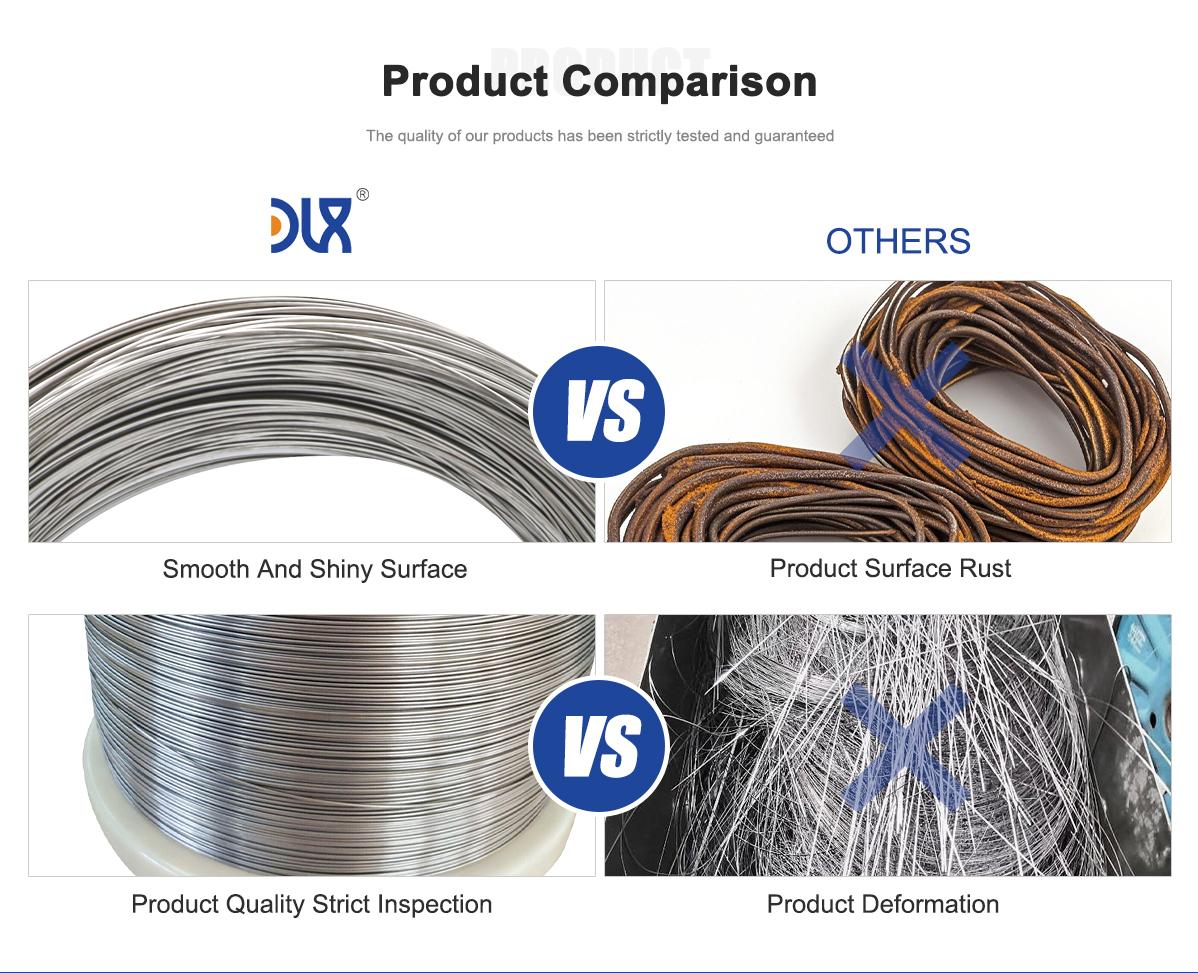

When it comes to comparing our company to the general market, we focus on what we do best: customization and quality control. Many suppliers offer standard alloys, but we tailor our Incoloy 800HT wire to specific client needs, like custom diameters or finishes for better weldability. Our in-house testing goes beyond industry standards—we simulate real petrochemical conditions with creep tests up to 10,000 hours, ensuring every batch exceeds ASME specs. This means our clients get wire that's not just compliant but optimized for longer service life, reducing replacement costs by up to 20-30%. We invest heavily in R&D, staying ahead of trends like hydrogen economy applications, where our alloy's hydrogen embrittlement resistance is a game-changer. Unlike generic options, our supply chain is streamlined for quick delivery, often within weeks, minimizing project delays. Plus, our technical support team helps with integration, from design to installation, something not every provider offers. In short, choosing us means partnering with experts who prioritize your system's stability.

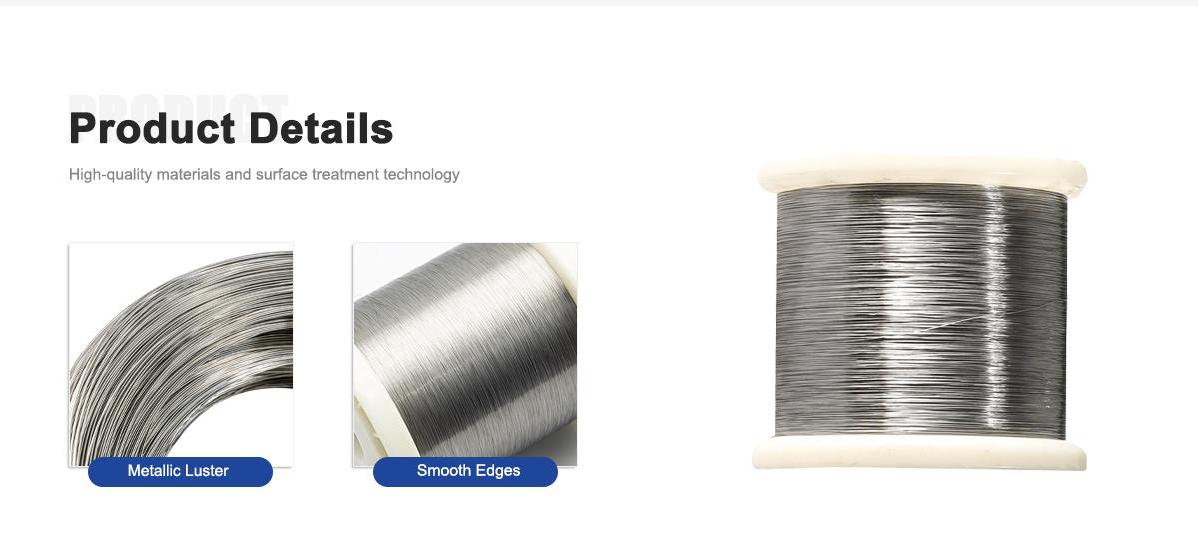

Diving deeper into the product, our Incoloy 800HT wire comes in various forms—round, flat, or shaped—to fit seamless integration. Mechanical properties are impressive: at room temperature, tensile strength hits 520 MPa, with yield at 205 MPa and 30% elongation for flexibility. But the real magic is at high temps; above 925°C, it retains over 80% of its strength, thanks to the controlled carbon and grain size. This prevents stress rupture, a common fail point in refining. We ensure eco-friendly production too, using recycled materials where possible, aligning with industry sustainability pushes. Clients in the Middle East have reported extended lifespans in their reformers, cutting maintenance by half.

Industry analysis wise, the refining sector faces volatility from oil prices, but growth in downstream chemicals is steady. Petrochemical demand for alloys like ours is booming, with projections showing a 6% CAGR through 2030. Challenges include supply chain disruptions, but our domestic sourcing mitigates that. We're also adapting to digital twins in plant design, where our wire's predictable performance aids simulations. In applications, it's not just about heat—corrosion from chlorides or acids in gas processing is handled effortlessly. For instance, in offshore rigs, it withstands H2S environments without pitting.

Our advantage? We don't cut corners on certification—every spool is traceable, with full mill test reports. Compared to market averages, our wire shows 15% better oxidation resistance in lab tests, thanks to proprietary annealing processes. This translates to real savings in petrochemical ops, where downtime costs millions. We've built long-term relationships by delivering consistent quality, helping clients meet regulatory demands like API standards.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Incoloy 800HT wire?

Incoloy 800HT wire is a high-performance nickel-iron-chromium alloy wire designed for stable operation in extreme high-temperature environments, offering excellent resistance to oxidation, carburization, and corrosion, particularly in petrochemical and refining systems.

What are the key materials and composition of Incoloy 800HT wire?

It primarily consists of nickel (30-35%), chromium (19-23%), iron (39.5% minimum), with controlled additions of aluminum and titanium (0.85-1.20% combined), and a carbon content of 0.06-0.10% for enhanced creep strength.

What are the main applications of Incoloy 800HT wire in the petrochemical industry?

It's widely used in reformer tubing, ethylene pyrolysis furnaces, hydrocarbon cracking equipment, and flare tips, where it provides reliable performance under prolonged high-temperature exposure and corrosive conditions.

How does Incoloy 800HT wire perform in refining systems?

In refining, it excels in applications like superheater and reheater tubing, bellows, and process piping, maintaining structural integrity at temperatures up to 1100°C (2010°F) while resisting sulfur attacks and oxidation.

What industry trends are driving the use of Incoloy 800HT wire?

Trends include increasing demand for energy efficiency in petrochemical plants, stricter environmental regulations pushing for durable materials, and growth in offshore oil and gas processing requiring corrosion-resistant alloys for longer equipment life.

What makes Incoloy 800HT wire suitable for high-temperature environments?

Its restricted chemistry and heat treatment ensure a stable face-centered cubic structure, providing superior creep and rupture strength above 700°C (1290°F), making it ideal for applications with frequent thermal cycling.

How does Incoloy 800HT wire resist corrosion?

It offers excellent resistance to oxidation, carburization, and nitridation in aqueous and gaseous environments, including nitric acid and sulfur compounds common in petrochemical refining.

What are the mechanical properties of Incoloy 800HT wire?

At room temperature, it has a tensile strength of about 520 MPa (75 ksi) and yield strength of 205 MPa (30 ksi), with elongation around 30%, and it retains high strength with minimal degradation at elevated temperatures.