Durable Hastelloy C22 UNS N06022 Strip for Marine and Pharmaceutical Chemical Processing

At DLX, we specialize in providing top-tier durable Hastelloy C22 UNS N06022 strip that's engineered for the toughest environments in marine and pharmaceutical chemical processing. Our Hastelloy C22 strip stands out because we've honed our manufacturing processes to deliver unmatched quality and reliability. If you're searching for Hastelloy C22 strip suppliers who prioritize precision and performance, you've come to the right place. Let's dive into what makes our durable Hastelloy C22 UNS N06022 strip a game-changer.

For more details, pls directly contact us.

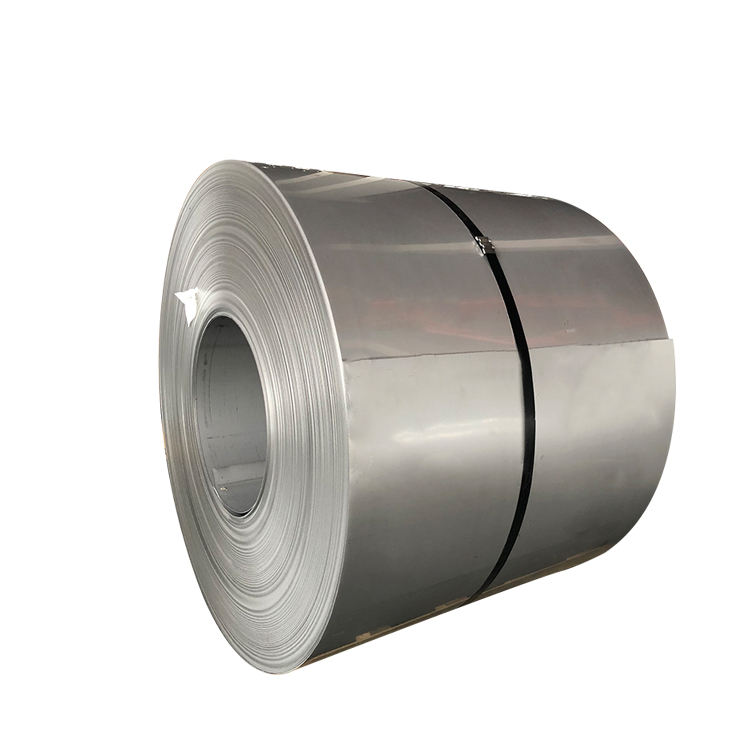

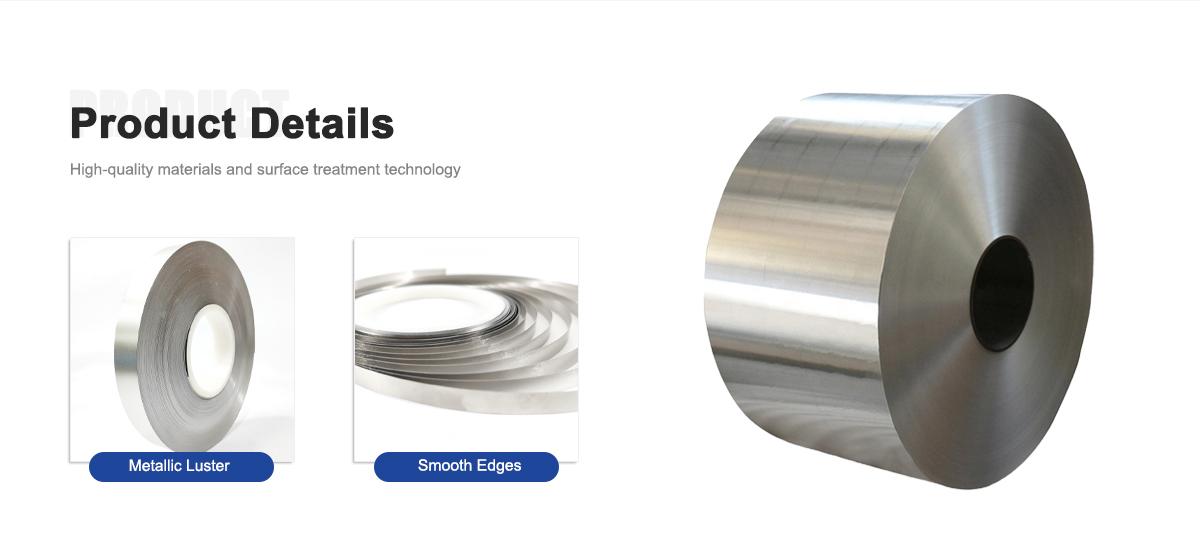

First off, our Hastelloy C22 strip is a nickel-chromium-molybdenum-tungsten alloy that's built to last. With UNS N06022 as its designation, this material packs a punch when it comes to corrosion resistance. Imagine a strip that can handle everything from aggressive acids to salty seawater without breaking a sweat—that's what we offer at DLX. The composition includes about 56% nickel for that solid base, 22% chromium for oxidation resistance, 13% molybdenum to fight off pitting and crevice attacks, and 3% tungsten for extra strength in harsh conditions. We keep iron low at around 3% to minimize any weak spots, and throw in trace elements like cobalt and vanadium for fine-tuning the properties. This isn't just any alloy; it's a versatile powerhouse that excels in both oxidizing and reducing media. At DLX, we source only the highest-grade raw materials to ensure every roll of Hastelloy C22 strip meets stringent standards like ASTM B575 and ASME SB575. Our strips come in various thicknesses, from 0.05mm to 3mm, and widths up to 600mm, making them perfect for custom fabrication. Whether you need it annealed for flexibility or cold-rolled for hardness, we've got options that fit your project seamlessly.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Now, let's talk about the industry landscape where our durable Hastelloy C22 UNS N06022 strip shines. The chemical processing sector is booming, driven by global demand for specialty chemicals, pharmaceuticals, and cleaner energy solutions. According to recent market analyses, the corrosion-resistant alloys market is projected to grow at over 5% annually through 2030, fueled by stricter environmental regulations and the push for sustainable manufacturing. In marine applications, offshore oil and gas exploration is ramping up, with a focus on materials that can withstand chloride-rich environments without failing prematurely. Pharmaceutical chemical processing is another hot area, where purity is paramount—any corrosion could lead to contamination, costing millions in recalls and downtime. Trends show a shift toward high-performance alloys like Hastelloy C22 strip because traditional materials just can't keep up with modern demands. For instance, the rise of biopharmaceuticals requires equipment that resists a wider range of aggressive agents, from acetic acid to hypochlorite solutions. At DLX, we're ahead of the curve by investing in R&D to adapt our Hastelloy C22 products to these evolving needs. We're seeing more clients in Asia-Pacific and North America turning to UNS N06022 strip for its longevity, which aligns with the industry's move toward reducing carbon footprints through durable, low-maintenance components.

When it comes to applications, our Hastelloy C22 strip is incredibly versatile, especially in marine and pharmaceutical chemical processing. In marine settings, think about heat exchangers on ships or offshore platforms—these strips form the backbone, resisting seawater corrosion that would eat through lesser materials. We've supplied Hastelloy C22 UNS N06022 strip for scrubber systems that clean exhaust gases, where it handles wet chlorine and sulfur compounds without pitting or cracking. Its stress corrosion cracking resistance is a big win in high-pressure underwater pipelines too. Switching to pharmaceutical chemical processing, our strip is ideal for reactors, tubing, and fittings where maintaining sterility is crucial. It stands up to strong oxidizers like ferric chlorides and cupric acids, preventing leaks that could compromise drug purity. We've seen it used in cellophane manufacturing and chlorination systems as well, but its real strength shows in avoiding contamination-related failures. Beyond these, industries like pollution control use it in flue gas desulfurization units, while waste management relies on it for incinerators handling hazardous materials. At DLX, we customize our durable Hastelloy C22 strip to fit specific applications, ensuring it performs under temperatures from -200°C to 400°C and in environments with pH extremes. This adaptability makes it a go-to for engineers tackling complex projects.

What sets DLX apart in this competitive field? While there are other suppliers out there offering similar alloys, our focus on excellence gives us a clear edge. We don't just sell Hastelloy C22 strip; we engineer it with precision that ensures superior performance every time. Our manufacturing process includes advanced melting techniques and rigorous quality controls that result in strips with consistent microstructure—no inclusions or defects that could lead to early failure. This means longer service life for your equipment, translating to real savings. Unlike generic options that might skimp on testing, every batch of our UNS N06022 strip undergoes ultrasonic and eddy current inspections, plus corrosion tests in simulated environments. We're committed to sustainability too, using recycled nickel where possible without compromising quality, which appeals to eco-conscious clients in marine and pharma sectors. Our supply chain is streamlined for quick delivery—whether you need small quantities for prototypes or bulk rolls for large-scale production, we deliver on time. Plus, our technical support team is always on hand to help with material selection, welding advice, or custom alloying. In a market where downtime can cripple operations, choosing DLX means investing in reliability that keeps your processes running smoothly.

Comparison Parameters Table

| Parameter | Hastelloy C22 (UNS N06022) Strip | Similar Nickel-Based Alloy (e.g., Higher Mo Variant) | Standard Stainless Steel (e.g., 316L Type) |

|---|---|---|---|

| Chemical Composition | Ni: 56%, Cr: 22%, Mo: 13%, W: 3%, Fe: 3% | Ni: 57%, Cr: 16%, Mo: 16%, W: 4%, Fe: 5% | Fe: Balance, Cr: 16-18%, Ni: 10-14%, Mo: 2-3% |

| Density (g/cm³) | 8.69 | 8.89 | 8.00 |

| Tensile Strength (MPa) | 690 (min) | 760 (min) | 485 (min) |

| Yield Strength (MPa) | 310 (min) | 345 (min) | 170 (min) |

| Elongation (%) | 45 (min) | 40 (min) | 40 (min) |

| Pitting Resistance Equivalent Number (PREN) | 45-50 | 45-50 | 25-30 |

| Corrosion Resistance | Excellent in oxidizing/reducing media, superior to many in wet chlorine and mixed acids | Strong in reducing environments, but less versatile in oxidizing ones | Good in mild corrosives, poor in chlorides and acids |

| Temperature Range (°C) | -200 to 400 (service) | -200 to 400 | -200 to 800 (but corrodes faster) |

| Weldability | Excellent, no sensitization | Good, but requires care | Good, but prone to intergranular corrosion |

| Typical Applications | Marine, pharma, chemical processing | Flue gas desulfurization, severe reducing acids | General food processing, mild chemicals |

| Cost Efficiency | High initial, low long-term maintenance | Similar, but may need more frequent checks | Lower initial, higher replacement costs |

Diving deeper into why our durable Hastelloy C22 UNS N06022 strip outperforms, consider its metallurgical stability. Heating or welding doesn't sensitize it, so you avoid intergranular corrosion that plagues other materials. This is huge in pharmaceutical applications where frequent sanitization cycles involve high heat and chemicals. In marine chemical processing, where salt spray and humidity are constant threats, our strip's high PREN (Pitting Resistance Equivalent Number) of around 45-50 ensures it holds up better than alloys with lower ratings. We've optimized the strip's surface finish to reduce crevice formation, further enhancing its resistance. Industry trends point to increased adoption of such advanced materials as companies aim for zero-defect manufacturing. For example, the pharmaceutical industry's growth, expected to hit $1.5 trillion by 2025, demands alloys like Hastelloy C22 for compliant, efficient operations. At DLX, we're not just following these trends; we're shaping them by collaborating with clients to develop bespoke solutions. Our R&D has led to enhanced versions of the strip with improved formability, making it easier to bend and shape without cracking.

Let's explore more on the applications front. In marine environments, our Hastelloy C22 strip is a staple for desalination plants, where it lines evaporators exposed to concentrated brines. Its ability to resist localized corrosion means fewer repairs in hard-to-access offshore setups. For pharmaceutical chemical processing, it's used in API (Active Pharmaceutical Ingredient) synthesis reactors, handling mixtures of nitric acid, hydrofluoric acid, and more. This prevents the kind of failures that could halt production lines. Extending to broader chemical industries, our strip finds use in acetic anhydride production and pesticide manufacturing, where versatility in wet and dry corrosives is key. Pollution control applications include wet scrubbers for power plants, tackling sulfuric acid mists. We've even supplied it for aerospace components indirectly tied to marine logistics, like fuel systems on ships. The common thread? Our durable Hastelloy C22 UNS N06022 strip delivers peace of mind in scenarios where failure isn't an option.

Comparing our approach at DLX to what's typically available, our advantages are evident in every aspect. We emphasize customer-centric innovation—while others might offer off-the-shelf products, we tailor our Hastelloy C22 strip to your exact specs, from alloy purity to dimensional tolerances. This customization reduces waste and improves integration into your systems. Our pricing model is transparent and competitive, reflecting the value of a product that lasts longer and performs better. In terms of supply reliability, we've built a global network that ensures steady availability, even during market fluctuations. Unlike suppliers who cut corners on certifications, we provide full traceability with mill test reports compliant to ISO 9001 and AS9100 standards. This is particularly beneficial in regulated industries like pharma, where documentation is as important as the material itself. Our commitment to ongoing improvement means we're constantly testing new heat treatments to boost the strip's fatigue resistance, giving you an edge in cyclic loading applications common in marine processing.

As the industry evolves, trends like digitalization in manufacturing are influencing how we produce and deliver Hastelloy C22 strip. At DLX, we're incorporating AI-driven quality checks to predict and prevent defects, ensuring every UNS N06022 product exceeds expectations. The push for green chemistry is another driver—our alloy's durability supports longer equipment lifecycles, reducing resource consumption. In marine sectors, with IMO regulations tightening on emissions, materials like our strip are essential for compliant scrubber tech. Pharmaceutical trends toward continuous manufacturing favor corrosion-resistant components that minimize batch variability. We're positioned perfectly to meet these demands, with scalable production that handles everything from R&D samples to industrial volumes.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Hastelloy C22 alloy?

Hastelloy C22 (UNS N06022) is primarily composed of nickel (about 56%), chromium (22%), molybdenum (13%), tungsten (3%), iron (3%), and trace elements like cobalt, manganese, silicon, vanadium, carbon, phosphorus, and sulfur.

What types of corrosion does Hastelloy C22 resist?

It offers exceptional resistance to pitting, crevice corrosion, stress corrosion cracking, intergranular corrosion, and general corrosion in both oxidizing and reducing environments, including exposure to strong oxidizers like ferric and cupric chlorides.

What are the key applications for Hastelloy C22 strip in marine environments?

It's used in offshore platforms, seawater piping, heat exchangers, and marine scrubbers where it withstands chloride-induced corrosion and harsh saltwater conditions.

How does Hastelloy C22 perform in pharmaceutical chemical processing?

It prevents contamination in reactors, tubing, fittings, and vessels by resisting corrosion from acids, chlorides, and other aggressive chemicals, ensuring purity in drug manufacturing.

What mechanical properties make Hastelloy C22 strip durable?

It has high ductility, excellent weldability, tensile strength around 690 MPa, yield strength of about 310 MPa, and elongation up to 45%, allowing it to handle extreme temperatures and pressures.

What industry trends are increasing demand for Hastelloy C22?

Growing focus on sustainability drives adoption in pollution control and waste management; expanding chemical and pharma sectors require more corrosion-resistant materials amid stricter regulations.

Can Hastelloy C22 strip be easily fabricated?

Yes, its ductility and weldability make it ideal for forming into strips, sheets, and components without sensitization during heating or welding.

How does Hastelloy C22 contribute to long-term cost savings in industries?

Its superior corrosion resistance reduces maintenance, downtime, and replacement needs, leading to lower operational costs in aggressive chemical and marine settings.