Stress-Corrosion Cracking Resistant Hastelloy C4 UNS N06455 Strip for Acidic Environments

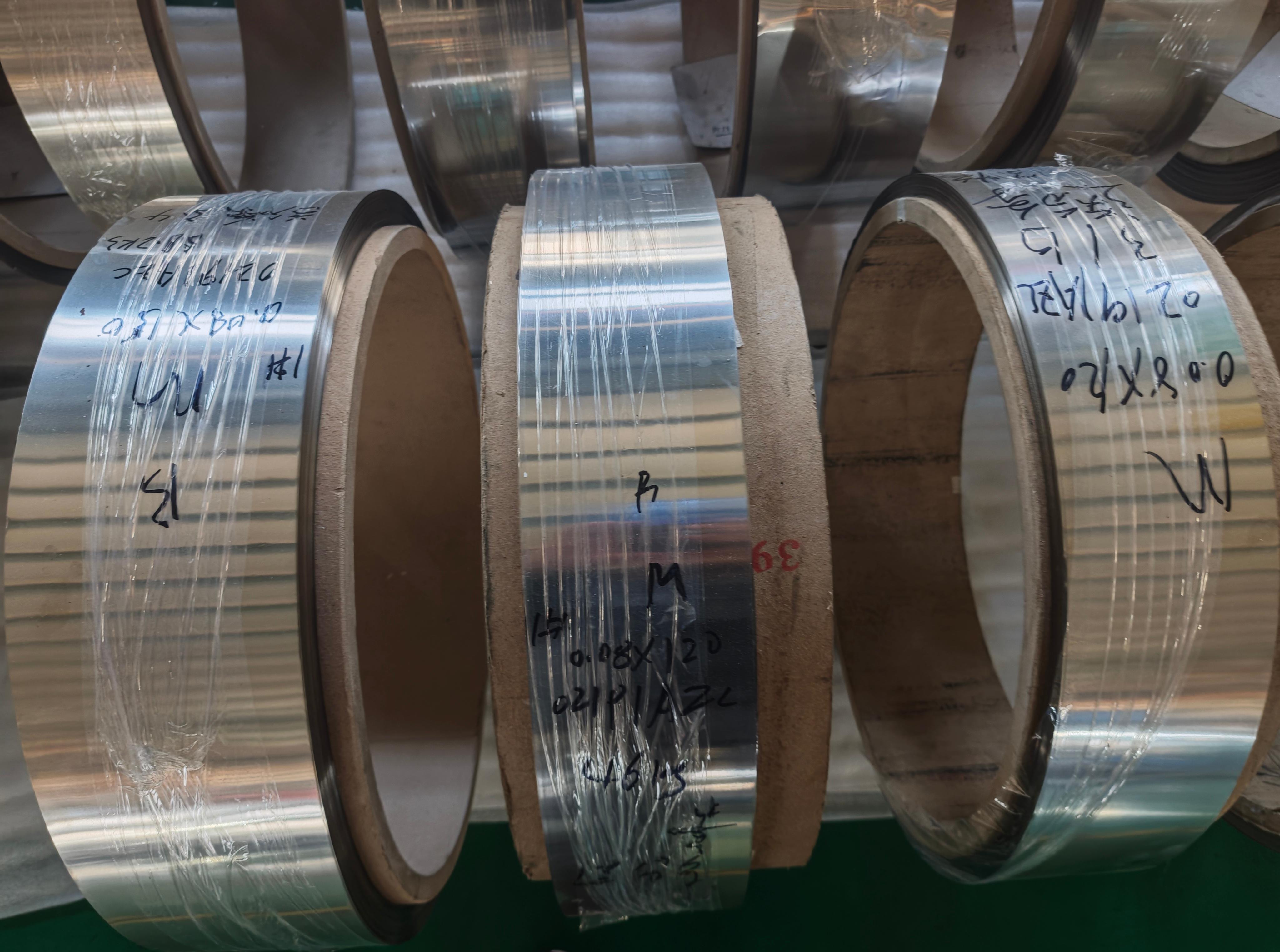

At DLX, we’re proud to offer our stress-corrosion cracking resistant Hastelloy C4 UNS N06455 strip, designed to tackle the toughest acidic environments in chemical processing. If you’re searching for top-quality Hastelloy C4 strip suppliers, you’ve landed in the right spot. Our UNS N06455 strip is a nickel-chromium-molybdenum alloy built to withstand aggressive acids and high-stress conditions without cracking under pressure. Picture a material that holds strong against sulfuric or hydrochloric acid while keeping your equipment running smoothly—that’s what we deliver. With roughly 65-70% nickel for a solid core, 14-18% chromium to fend off oxidation, 14-17% molybdenum to combat pitting, and a dash of titanium (up to 0.7%) for extra stability, this alloy is a beast. We keep iron low at 3% max to avoid weak points, and toss in trace manganese, silicon, and carbon for balance. This isn’t just any strip; it’s a precision-engineered solution for acidic, high-stress applications. At DLX, we stick to strict ASTM B575 and ASME SB575 standards, offering strips in thicknesses from 0.05mm to 3mm and widths up to 600mm. Whether you need it annealed for flexibility or cold-rolled for strength, we’ve got you covered for seamless fabrication.

For more details, pls directly contact us.

Let’s zoom out to the industry landscape where our Hastelloy C4 strip shines. The chemical processing sector is growing fast, with market reports forecasting a 4.5% annual growth rate through 2030, driven by demand for specialty chemicals and stricter environmental rules. Acidic environments are common in industries like oil and gas, where deep drilling exposes equipment to corrosive acids. Pollution control is another big player—think scrubbers handling acidic gases in power plants. Pharmaceuticals are also leaning hard into corrosion-resistant materials to ensure purity in drug manufacturing, especially with the rise of biopharma. Trends show a shift toward sustainable materials that last longer, reducing waste and downtime. Regulations like EPA standards are pushing companies to adopt alloys like Hastelloy C4 to prevent leaks in acidic setups. At DLX, we’re ahead of the game, supplying UNS N06455 strip to clients in North America, Europe, and Asia who need reliable solutions for high-stress, corrosive conditions. The industry’s move toward green tech favors our strip’s durability, which cuts down on replacements and aligns with eco-friendly goals.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

When it comes to applications, our stress-corrosion cracking resistant Hastelloy C4 strip is a versatile workhorse. In chemical processing, it’s perfect for reactors and piping exposed to acids like sulfuric, nitric, or phosphoric. Its resistance to stress-corrosion cracking makes it ideal for high-pressure systems in oil refineries, where welds face constant stress. We’ve supplied it for pollution control systems, like wet scrubbers tackling acidic sulfur compounds, and it holds up without pitting or cracking. In pharmaceuticals, it’s a go-to for welded vessels that handle aggressive cleaners during sterilization, ensuring no contamination. Beyond these, it’s used in waste incineration for handling acidic byproducts and in petrochemical plants for heat exchangers facing mixed acids. At DLX, we customize our Hastelloy C4 strip to thrive in temperatures from -200°C to 1038°C and in extreme pH levels, making it a favorite for engineers dealing with acidic, high-stress projects.

So, what makes DLX stand out in a crowded market? While there are other suppliers offering corrosion-resistant alloys, our focus on quality and innovation sets us apart. We don’t just produce Hastelloy C4 strip; we craft it with advanced vacuum melting and precision rolling to ensure a flawless microstructure—no inclusions that could lead to cracks. This means your equipment lasts longer, saving you on maintenance costs. Unlike some who skimp on testing, we run every batch through ultrasonic, eddy current, and acid exposure tests to guarantee performance. Sustainability is a big deal for us—we use recycled materials where possible without sacrificing strength, which resonates with clients aiming for greener operations. Our supply chain is fine-tuned for quick delivery, whether you need a small batch for R&D or bulk for production. Plus, our technical team is always ready to help with everything from alloy selection to welding tips. In acidic environments where failures can halt operations, choosing DLX means banking on reliability.

Digging into the technical edge of our Hastelloy C4 strip, its low carbon and silicon content prevents carbide precipitation during welding, avoiding sensitization that leads to stress-corrosion cracking. This is critical in acidic chemical plants where welds are under constant strain. With a PREN of 40-45, it’s a top performer against pitting in chloride-heavy acids. We’ve optimized the surface finish to reduce crevice formation, boosting resistance further. Industry trends like digital manufacturing are shaping how we produce, with DLX using AI-driven quality checks to catch defects early. The chemical industry’s projected $5.2 trillion valuation by 2025 highlights the need for alloys like UNS N06455 that support safe, scalable operations. We’re not just keeping up; we’re pushing the envelope with R&D that improves ductility for complex fabrications.

Comparison Parameters Table

| Parameter | Hastelloy C-4 (UNS N06455) Strip | Similar Nickel-Based Alloy (e.g., Higher Cr Variant) | Standard Stainless Steel (e.g., 316L Type) |

|---|---|---|---|

| Chemical Composition | Ni: 65-70%, Cr: 14-18%, Mo: 14-17%, Ti: ≤0.7%, Fe: ≤3% | Ni: 57%, Cr: 22%, Mo: 13%, W: 3%, Fe: 3% | Fe: Balance, Cr: 16-18%, Ni: 10-14%, Mo: 2-3% |

| Density (g/cm³) | 8.64 | 8.69 | 8.00 |

| Tensile Strength (MPa) | 690 (min) | 690 (min) | 485 (min) |

| Yield Strength (MPa) | 310 (min) | 310 (min) | 170 (min) |

| Elongation (%) | 40 (min) | 45 (min) | 40 (min) |

| Pitting Resistance Equivalent Number (PREN) | 40-45 | 45-50 | 25-30 |

| Corrosion Resistance | Superior in high-temperature acids and welded zones, excellent in reducing/oxidizing media | Versatile in mixed acids, but less stable at extreme heat | Adequate in mild environments, fails in acids and heat |

| Temperature Range (°C) | -200 to 1038 (service) | -200 to 400 | -200 to 800 (but degrades quickly) |

| Weldability | Outstanding, no sensitization | Excellent, minimal issues | Good, but risks intergranular attack |

| Typical Applications | High-temp chemical processing, welded reactors, pollution control | Marine, pharma, general chemicals | Food processing, basic piping |

| Cost Efficiency | Moderate initial, high long-term savings from durability | Similar, but may require more oversight | Low initial, frequent replacements needed |

More on applications—our Hastelloy C4 strip is a star in high-pressure acid gas pipelines, resisting cracking where others fail. In pollution control, it lines scrubbers and ducts handling hot, acidic gases. For pharmaceuticals, it ensures welded reactors stay contamination-free under harsh cleaning cycles. We’ve seen it in petrochemical heat exchangers and even aerospace-related acid transport systems. The common thread is its ability to handle stress and corrosion without breaking a sweat. Trends toward continuous manufacturing in pharma favor materials like our strip that maintain consistency under stress.

Comparing DLX to the typical supplier, our advantages are clear. We offer customization—while others push standard products, we tweak alloy compositions and dimensions to fit your needs, reducing waste and improving integration. Our pricing reflects the value of a strip that outlasts others in acidic conditions. We maintain a global supply network to ensure availability, even during market disruptions. Full traceability with ISO 9001 and AS9100 certifications gives you the documentation edge in regulated industries. Our R&D focuses on enhancing fatigue resistance for cyclic stress applications, common in chemical processing.

As the industry evolves, trends like automation and green chemistry are front and center. At DLX, we’re using predictive analytics to refine our Hastelloy C4 strip production, ensuring zero defects. Stricter regulations, like those from the EPA, drive demand for stress-corrosion cracking resistant materials in pollution control. In oil and gas, deeper wells mean harsher acids, where our strip excels. We’re ready to scale from prototypes to industrial volumes, meeting the needs of a growing market.

In short, our stress-corrosion cracking resistant Hastelloy C4 UNS N06455 strip is your ultimate solution for acidic environments, crafted by DLX to deliver unmatched performance. With its corrosion resistance, weldability, and alignment with industry trends, it’s the smart pick for reliable operations. Ready to power up your projects with premium Hastelloy C4 strip? DLX is here to make it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Hastelloy C-4 alloy?

Hastelloy C-4 (UNS N06455) consists primarily of nickel (balance, around 65-70%), chromium (14-18%), molybdenum (14-17%), with low iron (up to 3%), titanium (up to 0.7%), and trace elements like manganese, silicon, carbon, phosphorus, and sulfur.

What types of corrosion does Hastelloy C-4 resist?

It provides outstanding resistance to pitting, crevice corrosion, stress corrosion cracking, intergranular corrosion, and general corrosion in both oxidizing and reducing acids, including sulfuric, phosphoric, nitric, and hydrochloric acids.

What are the key applications for Hastelloy C-4 strip in high-temperature environments?

It's used in chemical reactors, heat exchangers, and piping systems where it maintains stability during welding and exposure to temperatures up to 1038°C.

How does Hastelloy C-4 perform in welded chemical applications?

Its microstructural stability prevents sensitization during welding, ensuring strong joints that resist cracking and corrosion in aggressive chemical processes.

What mechanical properties make Hastelloy C-4 strip thermally resistant?

It features high ductility, tensile strength around 690 MPa, yield strength of about 310 MPa, elongation up to 40%, and excellent thermal stability without precipitation hardening.

What industry trends are boosting demand for Hastelloy C-4?

Increasing focus on high-temperature chemical processing, stricter safety regulations in oil and gas, and the shift toward sustainable, long-lasting materials in pollution control and pharmaceuticals.

Can Hastelloy C-4 strip be easily welded and fabricated?

Yes, its weldability is superior due to low carbon and silicon content, allowing for forming, bending, and welding without loss of corrosion resistance or structural integrity.

How does Hastelloy C-4 contribute to efficiency in chemical industries?

Its thermal resistance and corrosion protection minimize downtime, extend equipment life, and reduce maintenance costs in high-heat, corrosive settings.