Reducing Acid-Resistant Hastelloy B-2 Strip for Sulfuric and Hydrochloric Acid Handling

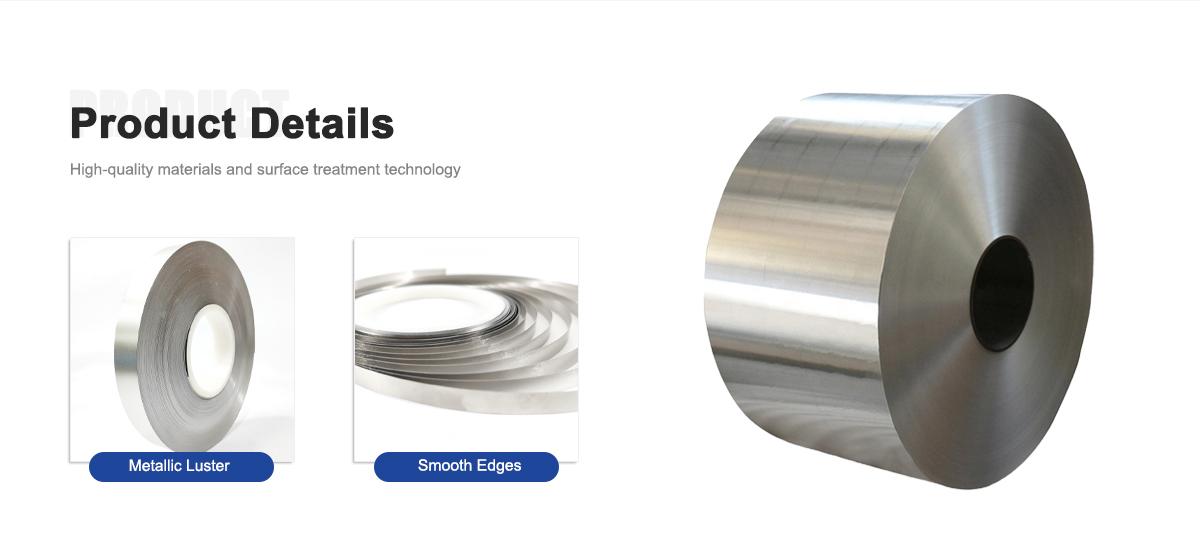

At DLX, we're excited about our reducing acid-resistant Hastelloy B-2 strip, perfect for handling sulfuric and hydrochloric acids in demanding chemical setups. If you're on the hunt for reliable Hastelloy B-2 strip suppliers, let's talk about why our UNS N10665 strip is a standout choice. This nickel-molybdenum alloy is engineered to thrive in reducing environments where other materials would falter. Imagine a strip that laughs off concentrated hydrochloric acid at boiling temps or sulfuric acid mixtures without pitting or cracking—that's the kind of toughness we deliver. With nickel making up about 68-70% for a sturdy base, 26-30% molybdenum to boost resistance in reducing acids, and minimal iron (under 2%) and chromium (under 1%) to avoid oxidation issues, it's optimized for purity. We keep carbon ultra-low at 0.01% max to prevent weld-zone problems, and add traces of cobalt, manganese, and silicon for balance. At DLX, we adhere to top standards like ASTM B333 and ASME SB333, producing strips in thicknesses from 0.05mm to 3mm and widths up to 600mm. Whether annealed for bendability or cold-rolled for durability, our Hastelloy B-2 strip fits right into your fabrication needs.

For more details, pls directly contact us.

Looking at the broader industry, the market for corrosion-resistant alloys like our Hastelloy B-2 strip is on a steady climb. Reports show the corrosion-resistant alloys sector growing at a CAGR of around 4.5-7% through 2025 and beyond, fueled by expanding chemical processing and oil and gas industries. In chemical handling, there's a big push for materials that can manage harsh reducing acids amid tighter environmental regulations. Sustainability is key—companies are seeking alloys that last longer to cut waste and emissions. The chemical processing market itself is evolving with trends like concentrated growth in specialty chemicals and advancements in corrosion protection tech. Offshore exploration and pharmaceutical manufacturing are ramping up demand for reducing acid-resistant solutions to prevent failures in aggressive environments. At DLX, we're right in the mix, supplying UNS N10665 strip to clients worldwide who need dependable performance. With global sales in corrosion inhibitors and alloys hitting billions, the focus on eco-friendly, durable materials aligns perfectly with our offerings, especially as regulations like EPA standards tighten on chemical safety.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Diving into applications, our reducing acid-resistant Hastelloy B-2 strip is a go-to for sulfuric and hydrochloric acid handling. In chemical plants, it's ideal for reactors and piping where these acids are processed or stored, resisting corrosion even in pure reducing conditions. We've provided it for heat exchangers in acetic acid production and pumps in phosphoric acid systems, where it prevents stress-corrosion cracking under load. Pharmaceuticals love it for equipment handling hydrogen chloride gas without contamination risks. Beyond that, it's used in pollution control for scrubbers dealing with acidic gases and in waste treatment for vessels exposed to mixed reducing agents. At DLX, we customize our strip for these scenarios, ensuring it performs from -200°C to 450°C and in low-pH setups. This makes it a favorite for engineers tackling projects involving aggressive chemicals, reducing the chance of leaks or breakdowns.

What gives DLX the upper hand in this space? While there are various suppliers out there for acid-resistant alloys, our commitment to excellence really shines through. We don't just roll out Hastelloy B-2 strip; we refine it with cutting-edge vacuum melting and strict quality checks to eliminate defects, ensuring uniform resistance across every inch. This translates to equipment that holds up longer, slashing your repair bills. Unlike options that might overlook rigorous testing, we subject each batch to ultrasonic inspections, acid immersion simulations, and mechanical stress tests. Sustainability matters to us—we incorporate recycled nickel to lessen environmental impact without compromising on strength, appealing to green-focused clients in chemical sectors. Our delivery is speedy and reliable, handling everything from prototype quantities to large-scale orders. And our support team is on call for advice on integration, welding, or custom specs. When dealing with sulfuric or hydrochloric acids, where corrosion can spell disaster, partnering with DLX means opting for proven reliability.

Let's get technical on why our Hastelloy B-2 strip excels in reducing acids. Its high molybdenum content provides unmatched protection against hydrochloric acid at all strengths and temps up to boiling, and it handles sulfuric acid concentrations up to 70% without issue. The low carbon design avoids grain-boundary precipitates during welding, so no sensitization or intergranular corrosion. This is crucial in acid-handling systems with frequent welds. Though PREN is high at 65-70 due to molybdenum, its real strength is in non-oxidizing media—avoid ferric ions or oxidants. We've optimized the strip's finish to minimize surface attacks, enhancing longevity. Industry trends like automation in chemical processing favor materials like ours that integrate with robotic fabrication. With the market eyeing $13 billion by 2034 for corrosion-resistant alloys, DLX is innovating to meet demands for scalable, safe solutions in acid environments.

Expanding on applications, our strip is essential in petrochemical refineries for hydrochloric acid stripping columns and in fertilizer production for sulfuric acid tanks. In pharmaceuticals, it safeguards reactors during API synthesis involving reducing acids. We've supplied it for vacuum distillation units and even aerospace chemical systems where purity is non-negotiable. The unifying factor? Superior resistance that keeps operations humming without unexpected halts. As trends shift toward strategic market growth in chemicals, our Hastelloy B-2 strip supports that by enabling efficient, low-maintenance setups.

Stacking DLX against typical alternatives, our edges are obvious. We emphasize tailoring—while some offer generic strips, we adjust thicknesses, tempers, and even minor compositions to match your acid-handling needs, cutting waste and boosting efficiency. Pricing is transparent, valuing the extended life our product provides in harsh conditions. Our global network ensures steady supply amid fluctuations. We provide full mill test reports compliant with ISO 9001, giving you an advantage in audits. R&D at DLX continually improves properties, like enhancing ductility for tighter bends in piping.

Comparison Parameters Table

| Parameter | Hastelloy B-2 (UNS N10665) Strip | Similar Nickel-Based Alloy (e.g., Higher Cr Variant) | Standard Stainless Steel (e.g., 316L Type) |

|---|---|---|---|

| Chemical Composition | Ni: 68-70%, Mo: 26-30%, Fe: ≤2%, Cr: ≤1% | Ni: 57%, Cr: 22%, Mo: 13%, W: 3%, Fe: 3% | Fe: Balance, Cr: 16-18%, Ni: 10-14%, Mo: 2-3% |

| Density (g/cm³) | 9.22 | 8.69 | 8.00 |

| Tensile Strength (MPa) | 760 (min) | 690 (min) | 485 (min) |

| Yield Strength (MPa) | 350 (min) | 310 (min) | 170 (min) |

| Elongation (%) | 40 (min) | 45 (min) | 40 (min) |

| Pitting Resistance Equivalent Number (PREN) | 65-70 | 45-50 | 25-30 |

| Corrosion Resistance | Superior in reducing acids like HCl and H2SO4, resists stress-corrosion cracking | Versatile in mixed/oxidizing media, less optimal in pure reducing acids | Good in mild corrosives, poor in strong reducing acids |

| Temperature Range (°C) | -200 to 450 (service) | -200 to 400 | -200 to 800 (but corrodes faster in acids) |

| Weldability | Excellent, no sensitization | Good, but requires care | Good, but prone to intergranular corrosion |

| Typical Applications | Sulfuric/hydrochloric acid handling, chemical reactors | Marine, pharma, general chemicals | Food processing, mild chemicals |

| Cost Efficiency | Higher initial, significant long-term savings in reducing environments | Similar, but may need more maintenance | Lower initial, higher replacement costs |

With 2025 trends highlighting tech advancements in corrosion protection, DLX is leveraging AI for predictive quality control on our Hastelloy B-2 production, spotting issues pre-shipment. The drive for sustainability in manufacturing boosts demand for long-lasting alloys, and our reducing acid-resistant options help comply with emission rules. In oil and gas, harsher drilling calls for robust materials like ours. We're equipped to handle diverse scales, from lab tests to industrial rolls.

To wrap it up, our reducing acid-resistant Hastelloy B-2 UNS N10665 strip is a powerhouse for sulfuric and hydrochloric acid handling, crafted by DLX to overcome industry challenges. Its corrosion resistance, weldability, and trend alignment make it the wise selection for efficient ops. Looking to strengthen your setups with premium Hastelloy B-2 strip? DLX is ready to deliver.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Hastelloy B-2 alloy?

Hastelloy B-2 (UNS N10665) is primarily nickel (balance, around 68-70%), molybdenum (26-30%), with low iron (up to 2%), chromium (up to 1%), cobalt (up to 1%), manganese (up to 1%), silicon (up to 0.1%), carbon (up to 0.01%), and trace phosphorus and sulfur.

What types of corrosion does Hastelloy B-2 resist?

It provides exceptional resistance to corrosion in reducing environments, including hydrochloric acid at all concentrations and temperatures, sulfuric acid, phosphoric acid, acetic acid, and hydrogen chloride gas, while resisting pitting, stress-corrosion cracking, and intergranular attack.

What are the key applications for Hastelloy B-2 strip in sulfuric and hydrochloric acid handling?

It's used in chemical reactors, piping, heat exchangers, pumps, valves, and vessels for processing and storing reducing acids in industries like chemical manufacturing and pharmaceuticals.

How does Hastelloy B-2 perform in reducing acidic conditions?

It maintains structural integrity and corrosion resistance in pure reducing acids without the need for heat treatment after welding, preventing carbide precipitation in weld zones.

What mechanical properties make Hastelloy B-2 strip resistant?

It has tensile strength around 760 MPa, yield strength of about 350 MPa, elongation up to 40%, and excellent ductility, allowing it to withstand high stresses in acidic environments.

What industry trends are increasing demand for Hastelloy B-2?

Rising demand in chemical processing for sustainable materials, stricter regulations on emissions and safety, growth in oil and gas exploration, and focus on corrosion protection in harsh environments drive adoption.

Can Hastelloy B-2 strip be easily welded for acid-handling applications?

Yes, its low carbon content ensures excellent weldability without sensitization, making it suitable for fabrication in reducing acid systems.

How does Hastelloy B-2 contribute to cost savings in acid handling?

Its superior resistance reduces equipment failures, maintenance needs, and downtime, leading to lower long-term operational costs in aggressive reducing acid settings.