Premium corrosion-resistant Hastelloy C-276 strip for chemical processing and pollution control

At DLX, we've been specializing in high-performance alloys for years, and our Premium Corrosion-Resistant Hastelloy C-276 Strip stands out as a game-changer for industries dealing with tough environments. This strip isn't just another material; it's engineered to handle the harshest conditions in chemical processing and pollution control systems. Made from a nickel-molybdenum-chromium blend with tungsten added for extra toughness, it fights off corrosion like nothing else. Whether you're building heat exchangers, reactors, or scrubbers, this strip delivers reliability that keeps operations running smoothly without constant repairs.

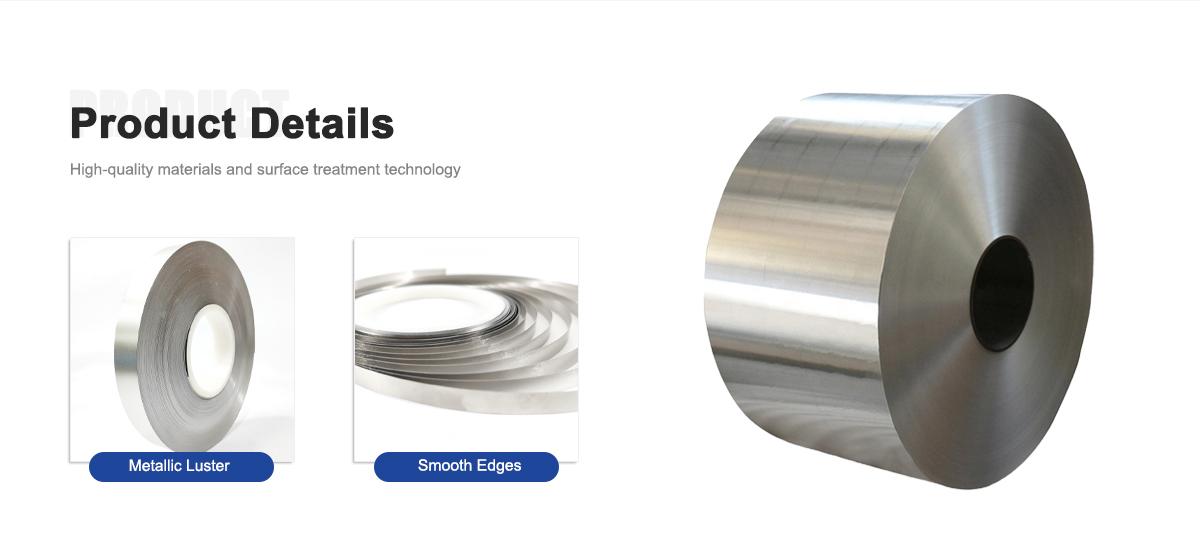

Let's talk about what makes our Hastelloy C-276 strip so special. First off, its composition is key: around 57% nickel as the base, 15-17% molybdenum for that killer resistance to reducing acids, 14.5-16.5% chromium to tackle oxidizing ones, and 3-4.5% tungsten to boost overall durability. This mix means it can stand up to pitting, crevice corrosion, and stress corrosion cracking—even in places where other materials would fail fast. We've seen it perform in temperatures up to 1900°F without losing its edge, and it's weldable without those pesky grain boundary issues that plague lesser alloys. At DLX, we precision-roll our strips to thicknesses from 0.05mm to 3mm, widths up to 600mm, and custom lengths, ensuring you get exactly what your project needs. Plus, our strips come with a smooth finish that minimizes buildup and eases fabrication.

For more details, pls directly contact us.

In the world of corrosion-resistant alloys, the industry is evolving quickly, especially as we hit 2025. Demand for materials like Hastelloy C-276 is skyrocketing, with market growth projected at a CAGR of 5-16% through 2033. Why? Because sectors like chemical processing and oil & gas are pushing for more sustainable, long-lasting solutions amid stricter environmental regs and rising operational costs. Corrosion costs industries billions annually—think downtime, repairs, and safety risks—so companies are shifting to advanced alloys that last longer and reduce waste. We've noticed a big trend toward eco-friendly manufacturing too; our Hastelloy C-276 strip helps cut emissions by enabling efficient pollution control systems that scrub out harmful gases without breaking down. In chemical plants, where aggressive media like sulfuric acid or chlorine are everyday hazards, this material is becoming the go-to for extending equipment life. And with global supply chains tightening, there's more focus on domestically sourced, high-quality strips to avoid delays. At DLX, we're ahead of this curve by investing in state-of-the-art rolling mills and quality testing, ensuring our products meet ASTM B575 specs and beyond.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Applications for our Premium Corrosion-Resistant Hastelloy C-276 Strip are vast, but let's zero in on chemical processing and pollution control, where it really shines. In chemical plants, it's perfect for lining reactors and evaporators that handle acidic slurries or high-pressure reactions. Imagine a setup processing phosphoric acid—our strip resists the corrosion that would eat through standard metals, keeping leaks and failures at bay. We've supplied it for transfer piping in facilities dealing with hydrochloric acid, where its ability to withstand both oxidizing and reducing environments prevents costly shutdowns. Switching to pollution control, this strip is a staple in flue gas desulfurization systems, or scrubbers, that remove sulfur dioxide from industrial exhaust. It handles moist chlorine and hypochlorite without pitting, helping plants meet emission standards while running efficiently. Wastewater treatment plants use it in tanks and pumps exposed to chlorides and organics, extending service life and cutting maintenance. Even in pulp and paper mills, where bleaching processes involve corrosive chemicals, our strip protects digesters and bleach towers. Real-world feedback from our clients shows reduced downtime by up to 50% compared to alternatives, proving its value in keeping operations green and profitable.

Now, when it comes to comparing what we offer at DLX versus what's out there from general suppliers, our advantages are clear without needing to name names. Many providers cut corners on quality control, leading to inconsistencies in alloy composition that can cause premature failure in critical applications. At DLX, every batch of Hastelloy C-276 strip undergoes rigorous testing for chemical uniformity, mechanical strength, and corrosion resistance—think ultrasonic inspections and salt spray tests to ensure zero defects. We don't just sell strips; we customize them with precision annealing for better formability, something generic suppliers often overlook, resulting in easier bending and welding for your fabricators. Price-wise, while some chase low costs with imported materials of questionable origin, we focus on value through longevity—our strips last longer, meaning fewer replacements and lower total ownership costs. We've heard stories of competitors' products cracking under stress corrosion after just months, but our clients report years of reliable service in the same conditions. Plus, our supply chain is rock-solid; with in-house inventory and fast turnaround, we deliver within weeks, not months, helping you avoid project delays. Sustainability is another edge—we source responsibly and recycle scraps, aligning with the industry's green shift, whereas others might not prioritize eco-practices.

Diving deeper into the industry analysis, 2025 is shaping up as a pivotal year for corrosion-resistant alloys. With global chemical production expected to rise by 3-4% annually, driven by demand in pharmaceuticals, fertilizers, and petrochemicals, materials like Hastelloy C-276 are essential for safe, efficient operations. Pollution control is booming too, thanks to regulations like the EU's Industrial Emissions Directive and U.S. EPA standards pushing for cleaner air and water. This means more investments in scrubbers and waste treatment tech, where our strip's resistance to chlorine dioxide and hypochlorite makes it indispensable. Emerging trends include additive manufacturing integration, where Hastelloy C-276 powders are used for 3D-printed parts, but strips remain king for traditional fabrication due to cost-effectiveness. Oil & gas exploration in corrosive offshore environments is another growth area, with Hastelloy C-276 strips used in downhole tools and pipelines to combat sour gas. Market forecasts show the alloy segment reaching $1.8-2 billion by 2033, fueled by Asia-Pacific's industrial boom and North America's focus on infrastructure upgrades. Challenges like raw material price volatility—nickel and molybdenum costs fluctuate—but at DLX, we hedge through long-term contracts to keep pricing stable for our customers.

From an application standpoint, let's explore how our Hastelloy C-276 strip fits into modern systems. In a typical chemical processing plant, it might form the core of a heat exchanger handling ferric chloride solutions. Its low carbon content prevents carbide precipitation during welding, ensuring joints stay strong and leak-free. For pollution control, picture a wet scrubber in a power plant: our strip lines the vessel walls, resisting the acidic slurry that forms when lime reacts with SO2. This not only extends the system's life but also boosts efficiency, reducing energy use and emissions. In marine applications, though not the primary focus, it's great for desalination plants where seawater corrosion is a threat. We've customized strips for hybrid systems combining chemical and environmental controls, like in waste incinerators where high temps and corrosive gases meet. Clients appreciate how our product maintains mechanical properties—tensile strength around 100 ksi—even after prolonged exposure, unlike materials that weaken over time.

Comparison Parameters Table for Hastelloy C-276 vs. Standard Austenitic Stainless Steels (e.g., 316L Type)

| Parameter | Hastelloy C-276 | Standard Austenitic Stainless Steel (e.g., 316L) |

|---|---|---|

| Chemical Composition | Ni: 57% (balance), Mo: 15-17%, Cr: 14.5-16.5%, Fe: 4-7%, W: 3-4.5% | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Fe: Balance |

| Corrosion Resistance | Excellent in pitting, crevice, and stress cracking; resists strong acids like HCl and H2SO4 up to boiling points | Good in mild environments; susceptible to pitting in chlorides and acids above certain concentrations |

| Temperature Range | Up to 1900°F (1038°C) with oxidation resistance | Up to 1600°F (871°C); prone to scaling at high temps |

| Tensile Strength (ksi) | 100-120 (at room temp) | 70-90 (at room temp) |

| Yield Strength (ksi) | 45-60 | 25-40 |

| Elongation (%) | 40-50 | 40-50 |

| Density (g/cm³) | 8.89 | 8.0 |

| Applications Suitability | High for chemical processing, pollution control in aggressive media | Moderate for general use; limited in severe corrosive settings |

| Weldability | Excellent, no grain boundary precipitation | Good, but requires care to avoid sensitization |

Highlighting DLX's edge again, our in-house expertise sets us apart. While some suppliers offer off-the-shelf products with minimal support, we provide technical consultations to optimize strip selection for your specific pH levels, temperatures, and pressures. Our R&D team constantly refines processes, like advanced cold-rolling for tighter tolerances, giving you strips with superior flatness and edge quality. Delivery reliability is huge; in an era of supply disruptions, our domestic production means no customs hassles or tariffs spiking costs. And on the sustainability front, our manufacturing uses energy-efficient tech, cutting carbon footprints—aligning perfectly with industry trends toward net-zero goals by 2050. Customers tell us this holistic approach saves them money long-term, with ROI often seen in under a year through reduced failures.

Wrapping up the product side, our Premium Corrosion-Resistant Hastelloy C-276 Strip isn't just durable; it's versatile for forming into coils, sheets, or custom shapes. We offer finishes from bright annealed to pickled, depending on your needs for aesthetics or functionality. Compliance with standards like UNS N10276 ensures it meets global requirements, and our certifications back that up. If you're in chemical processing or pollution control, this strip could transform your operations—fewer breakdowns, better compliance, and ultimately, higher profits.

Looking ahead, the industry trends point to even more innovation. With AI and IoT integrating into plants for predictive maintenance, materials like ours will be monitored in real-time to prevent corrosion before it starts. Electric vehicle battery production is another emerging application, where Hastelloy C-276 handles the acidic electrolytes safely. At DLX, we're gearing up for this by expanding capacity and exploring alloy enhancements. In summary, choosing our Hastelloy C-276 strip means investing in reliability, efficiency, and future-proofing your business. We're committed to delivering the best, because in tough environments, second-best just doesn't cut it.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Hastelloy C-276?

Hastelloy C-276 is a nickel-molybdenum-chromium alloy designed for superior corrosion resistance in harsh environments, including resistance to pitting, crevice corrosion, and stress corrosion cracking.

What are the key material properties of Hastelloy C-276?

It offers excellent resistance to oxidizing and reducing acids, with high molybdenum content for reduction corrosion protection, and maintains integrity up to 1900°F.

What are common applications for Hastelloy C-276 strip?

It's widely used in chemical processing for heat exchangers and reactors, pollution control systems like scrubbers, and industries such as pulp and paper production.

How does Hastelloy C-276 perform in chemical processing?

It withstands aggressive chemicals like sulfuric acid, hydrochloric acid, and chlorine, making it ideal for evaporators, transfer piping, and reaction vessels.

What role does Hastelloy C-276 play in pollution control?

In pollution control, it resists moist chlorine, hypochlorite, and chlorine dioxide, commonly used in wastewater treatment, incineration, and scrubber systems.

What are the industry trends for corrosion-resistant alloys like Hastelloy C-276 in 2025?

Demand is growing at a CAGR of around 5-16% due to expanding chemical and oil & gas sectors, with focus on sustainable, high-performance materials for harsh environments.

How is Hastelloy C-276 maintained for longevity?

Regular inspections, avoiding prolonged exposure to temperatures above 1000°F to prevent precipitation, and proper welding practices ensure optimal performance.

What makes Hastelloy C-276 versatile compared to other materials?

Its ability to resist both oxidizing and non-oxidizing acids, along with weldability without grain boundary issues, sets it apart in versatile applications.