Robust Hastelloy B2 UNS N10665 Strip for Chemical Processing and Vacuum Furnace Systems

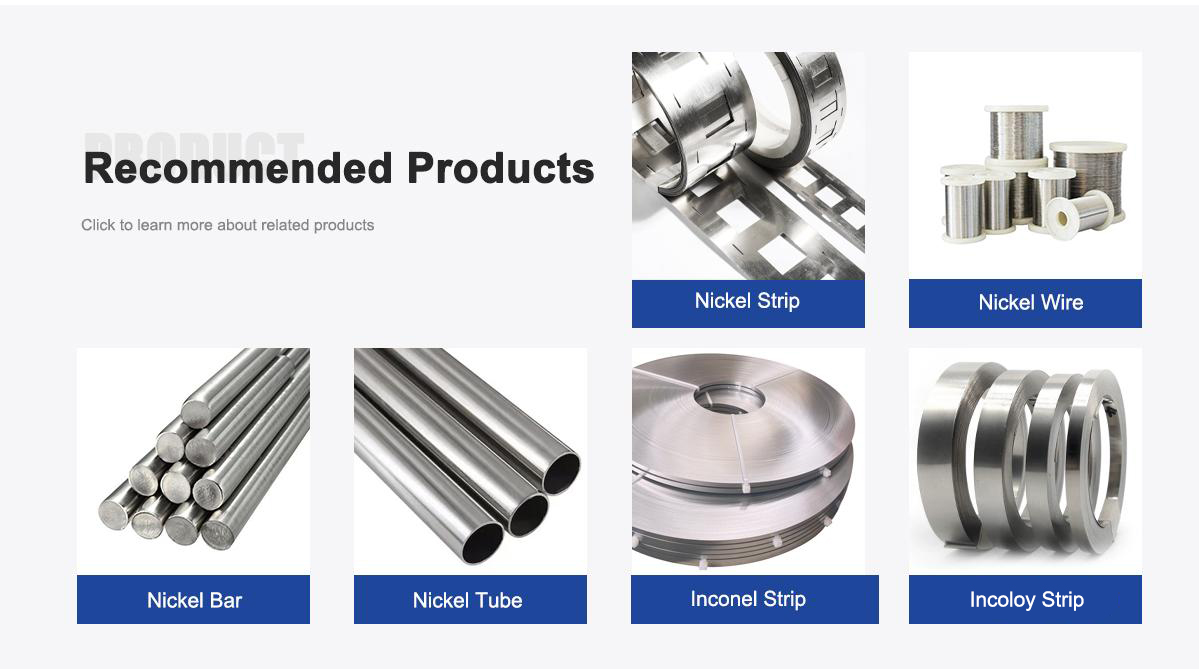

At DLX, we're all in on our robust Hastelloy B2 UNS N10665 strip, tailored for the rigors of chemical processing and vacuum furnace systems. If you're scouting for dependable Hastelloy B2 strip suppliers who deliver quality without the hassle, here's why our UNS N10665 strip is a solid pick. This nickel-molybdenum alloy is built tough for reducing environments where corrosion could wreck havoc. Think of it as your go-to material that stands up to hydrochloric acid at any concentration or sulfuric acid blends, all while keeping things stable in high-heat vacuum setups. With nickel clocking in at 68-70% for that strong backbone, 26-30% molybdenum to amp up resistance in reducing acids, and super low iron (under 2%) and chromium (under 1%) to dodge oxidation pitfalls, it's fine-tuned for performance. We cap carbon at 0.01% to skip weld issues, and mix in tiny bits of cobalt, manganese, and silicon for the right balance. At DLX, we follow rigorous ASTM B333 and ASME SB333 specs, rolling out strips from 0.05mm to 3mm thick and up to 600mm wide. Annealed for easy forming or cold-rolled for extra strength, our Hastelloy B2 strip slots perfectly into your projects.

For more details, pls directly contact us.

Shifting to the industry scene, the market for alloys like our Hastelloy B2 strip is heating up. Recent reports peg the Hastelloy market at about $5.87 billion in 2024, set to hit $6.09 billion in 2025 and climb to $8.50 billion by 2034 with a 3.8% CAGR. Nickel-based superalloys are booming too, expected to grow at 6.6% CAGR from 2025 to 2032, driven by aerospace, energy, and chemical demands. In chemical processing, tighter regs on emissions and safety are pushing for durable materials that cut leaks and downtime. Vacuum furnace systems are seeing growth with advances in semiconductors and metallurgy, where reducing atmospheres demand alloys that won't degrade. Trends point to sustainability—firms want long-lasting strips to slash waste and energy use. The superalloys market is projected to jump from $7.82 billion in 2025 to $17.75 billion by 2032 at 12.4% CAGR, fueled by high-temp needs in power gen and aerospace. At DLX, we're tuned into this, supplying UNS N10665 strip to global clients chasing efficiency in chemical and furnace ops. With nickel base alloys forecasted to reach $5,667.61 million by 2030 at 2.6% CAGR, the focus on corrosion fighters like ours is clear. Eco-trends are big, with recycled materials and low-emission processes boosting demand for robust options.On applications, our robust Hastelloy B2 strip nails it in chemical processing and vacuum furnace systems. In chem plants, it's spot-on for reactors handling hydrochloric or sulfuric acids, fending off corrosion in reducing setups.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

What puts DLX a cut above in this arena? Sure, there are suppliers peddling similar alloys, but our edge comes from laser-focused quality. We craft Hastelloy B2 strip with top-tier vacuum melting and precision controls, ditching defects for even resistance throughout. That means your systems run longer, trimming those pesky repair costs. While some skip the deep dives, we test every roll with ultrasonics, acid soaks, and heat cycles to lock in performance. Green creds? We blend in recycled nickel to ease the planet's load, no quality drop—perfect for sustainability-driven chemical and furnace folks. Delivery's a breeze with our streamlined chain, from small R&D batches to big production hauls. Our crew's on deck for tips on welding, custom fits, or alloy tweaks. In worlds where acid eats gear or heat warps parts, DLX delivers the robustness that keeps you ahead.

Comparison Parameters Table

| Parameter | Hastelloy B2 (UNS N10665) Strip | Similar Nickel-Based Alloy (e.g., Higher Cr Variant) | Standard Stainless Steel (e.g., 316L Type) |

|---|---|---|---|

| Chemical Composition | Ni: 68-70%, Mo: 26-30%, Fe: ≤2%, Cr: ≤1% | Ni: 57%, Cr: 22%, Mo: 13%, W: 3%, Fe: 3% | Fe: Balance, Cr: 16-18%, Ni: 10-14%, Mo: 2-3% |

| Density (g/cm³) | 9.22 | 8.69 | 8.00 |

| Tensile Strength (MPa) | 760 (min) | 690 (min) | 485 (min) |

| Yield Strength (MPa) | 350 (min) | 310 (min) | 170 (min) |

| Elongation (%) | 40 (min) | 45 (min) | 40 (min) |

| Pitting Resistance Equivalent Number (PREN) | 65-70 | 45-50 | 25-30 |

| Corrosion Resistance | Exceptional in reducing acids and atmospheres, resists stress-cracking | Good in mixed media, less in pure reducing | Moderate in mild, fails in reducing acids |

| Temperature Range (°C) | -200 to 450 (service) | -200 to 400 | -200 to 800 (degrades in heat/acids) |

| Weldability | Outstanding, no sensitization | Excellent, minimal issues | Good, risks intergranular corrosion |

| Typical Applications | Chemical processing reactors, vacuum furnace components | Marine, pharma, oxidizing chemicals | Food processing, basic piping |

| Cost Efficiency | Higher upfront, major savings in reducing environments | Similar, but higher maintenance in specifics | Low initial, frequent replacements needed |

Let's break down why our Hastelloy B2 strip rocks technically. High molybdenum zaps corrosion in hydrochloric acid up to boiling and sulfuric up to 70%, minus ferric ions or oxidants. Low carbon skips precipitates in welds, no sensitization or intergranular hits—key for chemical piping and furnace welds. PREN hits 65-70 thanks to molybdenum, but it shines in non-oxidizing zones. We've smoothed surfaces to cut attacks, upping life spans. Trends like AI in manufacturing? We're using it for predictive checks on UNS N10665 production, nailing flaws early. The Ni-based superalloy market's eyeing $8.2 billion by 2032 from $5 billion in 2023, underscoring needs for high-performers like ours. DLX innovates with R&D boosting ductility for intricate furnace designs.

For more details, pls directly contact us.

About Us:

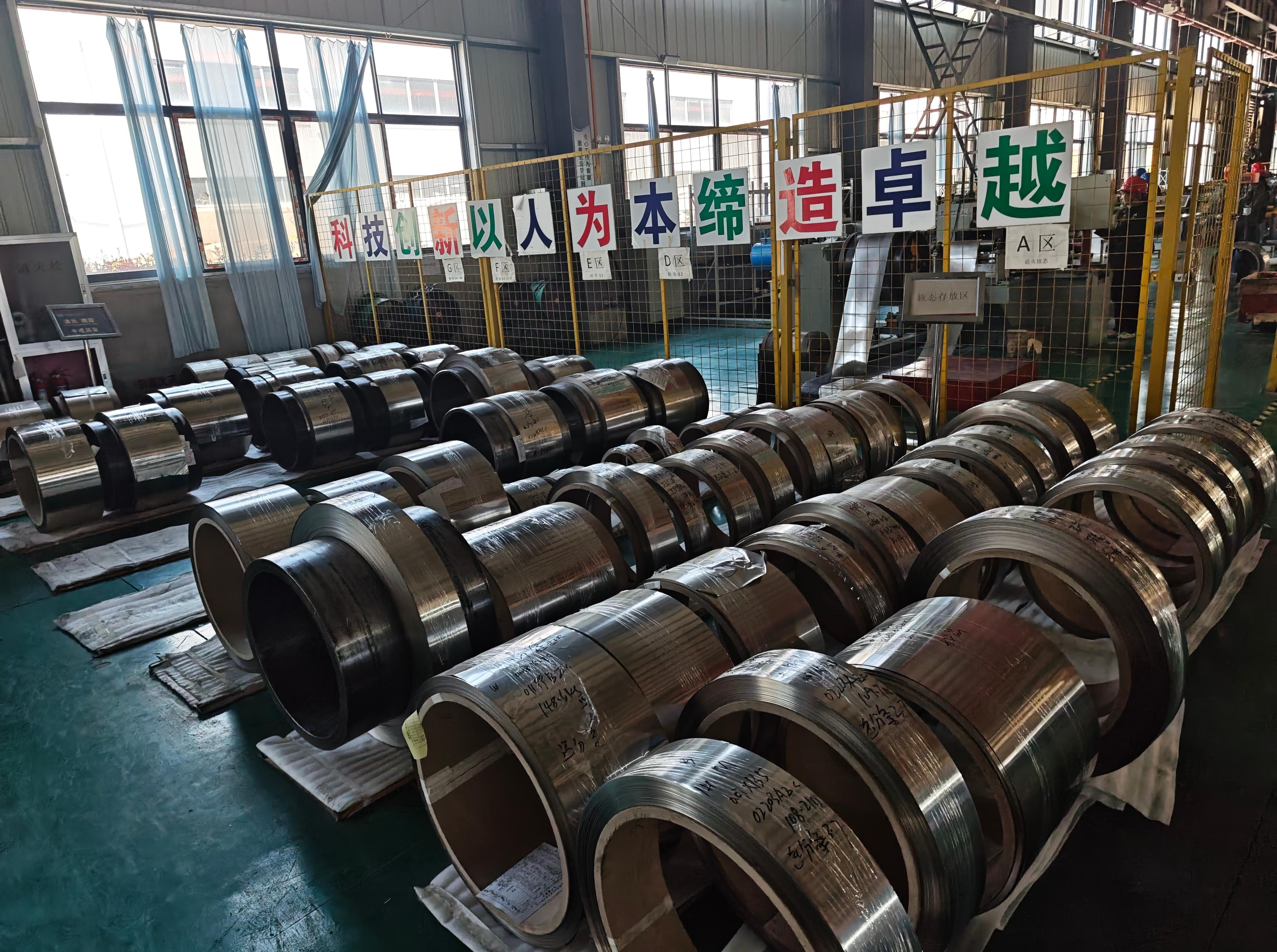

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Hastelloy B2 alloy?

Hastelloy B2 (UNS N10665) is mainly nickel (68-70%), molybdenum (26-30%), with low iron (up to 2%), chromium (up to 1%), cobalt (up to 1%), manganese (up to 1%), silicon (up to 0.1%), carbon (up to 0.01%), and trace phosphorus and sulfur.

What types of corrosion does Hastelloy B2 resist?

It offers superior resistance to corrosion in reducing environments, including pitting, stress-corrosion cracking, intergranular attack, and general corrosion from hydrochloric, sulfuric, phosphoric, and acetic acids, as well as hydrogen chloride gas.

What are the key applications for Hastelloy B2 strip in chemical processing and vacuum furnace systems?

In chemical processing, it's used for reactors, piping, heat exchangers, and valves handling reducing acids; in vacuum furnaces, it serves in mechanical components, expansion bellows, and fixtures where reducing atmospheres prevent oxidation.

How does Hastelloy B2 perform in vacuum furnace environments?

It maintains stability in high-temperature, low-oxygen reducing conditions, resisting carbide precipitation and corrosion without post-weld heat treatment, ideal for furnace parts exposed to aggressive gases.

What mechanical properties make Hastelloy B2 strip robust?

It features tensile strength around 760 MPa, yield strength of about 350 MPa, elongation up to 40%, high ductility, and thermal stability up to 450°C, ensuring durability under stress and heat.

What industry trends are boosting demand for Hastelloy B2?

Growing chemical processing sector, advancements in aerospace and energy, stricter safety regulations, and focus on sustainable, corrosion-resistant materials amid market growth projected at 5.5% CAGR through 2033.

Can Hastelloy B2 strip be easily fabricated for chemical and furnace use?

Yes, its low carbon content provides excellent weldability and formability without sensitization, making it suitable for bending, welding, and shaping in reducing chemical and vacuum setups.

How does Hastelloy B2 strip enhance efficiency in chemical processing and vacuum systems?

Its resistance to reducing corrosives and high-heat stability reduces failures, maintenance, and downtime, leading to cost-effective operations in harsh environments.