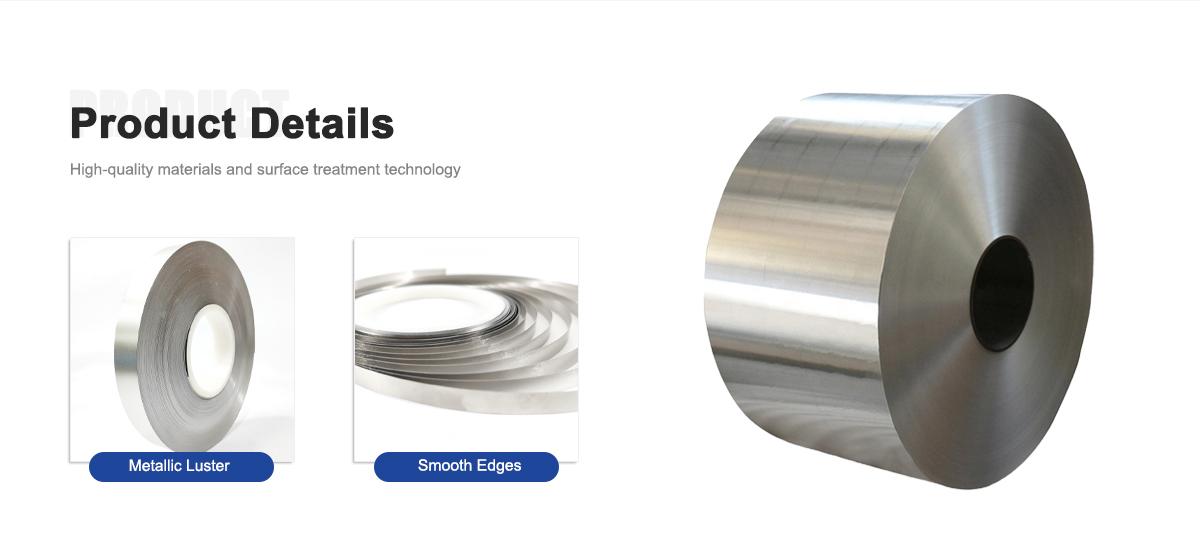

Versatile Pitting-Resistant Hastelloy C-22 Strip for Wet Chlorine and Oxidizing Media Applications

At DLX, our Versatile Pitting-Resistant Hastelloy C-22 Strip is a standout choice for industries battling tough corrosive environments like wet chlorine and oxidizing media. This isn’t just any alloy strip—it’s a high-performance solution crafted to protect your equipment where standard materials would fail. Built from a nickel-chromium-molybdenum blend with a touch of tungsten, it’s designed to resist pitting, crevice corrosion, and stress corrosion cracking, making it a go-to for chemical processing and pollution control systems. Whether you’re running a reactor in a chemical plant or a scrubber in a waste treatment facility, our Hastelloy C-22 strip keeps things running smoothly, saving you from costly downtime.

For more details, pls directly contact us.

Let’s break down what makes this strip so special. Hastelloy C-22, or UNS N06022, has a unique composition: nickel as the base for flexibility, 20-22.5% chromium for top-notch resistance to oxidizing acids, 12.5-14.5% molybdenum to tackle reducing environments, and 2.5-3.5% tungsten to boost pitting resistance. This combo makes it a champ against wet chlorine, hypochlorite, and mixed acids like nitric and sulfuric. At DLX, we precision-roll our strips to thicknesses from 0.05mm to 3mm, widths up to 600mm, and custom lengths to fit your needs. We also fine-tune the finish—think bright annealed or pickled—for easier fabrication and less residue buildup. It holds strong up to 1250°F, and its low carbon content ensures welds stay corrosion-resistant without grain boundary issues. That means your equipment lasts longer, even in the harshest conditions.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

The industry for corrosion-resistant alloys like Hastelloy C-22 is thriving in 2025, with the global market projected to grow at a CAGR of 5-6% through 2030. Why the boom? Chemical processing is expanding, driven by demand for specialty chemicals, pharmaceuticals, and green energy solutions like battery production. Stricter environmental regulations, like the EU’s Industrial Emissions Directive and U.S. EPA standards, are pushing companies to invest in materials that can handle aggressive media without breaking down. Corrosion costs industries billions yearly—think equipment failures and lost production—so high-performance alloys are in demand to cut those losses. We’re seeing a shift toward sustainable manufacturing too, with plants aiming for net-zero emissions by 2050. Our Hastelloy C-22 strip supports this by enabling efficient pollution control systems that reduce emissions while staying durable. Asia-Pacific is a hotspot for growth, with chemical and pulp industries scaling up, while North America focuses on upgrading aging infrastructure. Price volatility for nickel and molybdenum is a challenge, but at DLX, we secure stable supplies to keep costs predictable for our customers.

Applications for our Hastelloy C-22 strip are wide-ranging, but it really shines in wet chlorine and oxidizing media environments. In chemical processing, it’s a lifesaver for reactors and heat exchangers handling nitric acid or chlorine-based compounds. For example, in a plant producing chlorinated solvents, our strip lines vessels to prevent pitting from wet chlorine gas, extending equipment life by years. Pollution control is another big area—think flue gas desulfurization systems where scrubbers face chlorine dioxide and hypochlorite. Our strip resists these corrosives, helping plants meet emission standards without constant repairs. In pharmaceuticals, it’s used in synthesis reactors where purity is critical, resisting acidic intermediates that would eat through lesser materials. Pulp and paper mills rely on it for bleach plants, where oxidizing agents like chlorine dioxide are common. Even in waste treatment, it handles acidic slurries in tanks and piping, cutting maintenance by up to 50%, based on client feedback. Its versatility makes it a fit for mixed acid environments, where both oxidizing and reducing conditions are present.

Comparison Parameters Table for Hastelloy C-276 vs. 316L Stainless Steel

| Parameter | Hastelloy C-276 | 316L Stainless Steel |

|---|---|---|

| Chemical Composition | Ni: Balance, Mo: 15-17%, Cr: 14.5-16.5%, Fe: 4-7%, W: 3-4.5% | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Fe: Balance, C: ≤0.03% |

| Corrosion Resistance | Superior in pitting, crevice, and stress cracking; resists strong acids like HCl and H2SO4 in oxidizing/reducing environments | Good in mild corrosives; vulnerable to chlorides and acids at higher concentrations |

| Temperature Range | Up to 1900°F (1038°C) with excellent oxidation resistance | Up to 1600°F (871°C); susceptible to scaling and embrittlement |

| Tensile Strength (ksi) | 100-120 (room temp) | 70-90 (room temp) |

| Yield Strength (ksi) | 45-60 | 25-40 |

| Elongation (%) | 40-50 | 40-50 |

| Density (g/cm³) | 8.89 | 8.0 |

| Applications Suitability | High for severe acid environments in chemical processing | Moderate for general use; limited in aggressive acids |

| Weldability | Excellent, resistant to grain boundary issues | Good, but prone to sensitization in heat-affected zones |

When you stack up what DLX offers against typical market suppliers, our edge is clear. Many providers cut corners on quality, delivering strips with inconsistent alloy mixes that crack under stress or pit in chlorine-heavy settings. At DLX, every batch undergoes strict testing—ultrasonic scans, salt spray tests, you name it—to ensure zero defects. We customize beyond the basics, offering tailored annealing for better formability, which means your fabricators save time and effort. While some suppliers lean on imported materials with shaky quality and long lead times, our domestic production delivers within weeks, keeping your projects on track. Price is a factor, but we focus on long-term value—our strips last longer, reducing replacement costs. We’ve heard horror stories of generic strips failing in wet chlorine systems within months, while ours keep going for years. Sustainability is another win; our energy-efficient mills and scrap recycling align with the industry’s green push, something not every supplier prioritizes.

Zooming into the industry trends, 2025 is a pivotal year. Chemical production is set to grow 3-4% annually, with pharmaceuticals and agrochemicals leading the charge. Regulations are tightening globally, demanding materials that withstand corrosive media to prevent leaks and emissions. In pollution control, investments in scrubbers and wastewater systems are rising to meet standards like the Clean Air Act. Hastelloy C-22’s ability to handle oxidizing acids and chlorides makes it a top pick for these applications. Emerging trends include integrating alloys with smart tech—think IoT sensors for corrosion monitoring—which boosts demand for reliable strips like ours. The oil and gas sector, especially offshore, uses it for sour gas environments, though wet chlorine applications are more common. Market reports peg the corrosion-resistant alloy segment at $1.5 billion by 2030, with Hastelloy C-22 strips gaining traction for their versatility. Supply chain issues persist, but our in-house inventory and local sourcing keep us ahead.

For specific applications, picture a scrubber in a coal-fired plant. Our Hastelloy C-22 strip lines the interior, resisting chlorine dioxide and acidic mists that form during sulfur removal. In pharmaceutical cleanrooms, it’s used in piping for acid-based drug synthesis, ensuring no contamination. Pulp mills use it in digesters facing oxidizing bleaches, where its 100-130 ksi tensile strength holds up under pressure. We’ve tailored strips for hybrid systems, like waste incinerators dealing with both wet chlorine and acidic gases, where its resistance to pitting saves the day. The strip’s mechanical properties—45-65 ksi yield strength and 45-55% elongation—make it easy to form into complex shapes without cracking, even in dynamic systems.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Hastelloy C-276 UNS N10276?

Hastelloy C-276 UNS N10276 is a nickel-molybdenum-chromium-tungsten alloy known for its exceptional corrosion resistance in severe environments, including both oxidizing and reducing acids.

What are the key material properties of Hastelloy C-276 strip?

It features high resistance to pitting, crevice corrosion, and stress corrosion cracking, with excellent weldability and stability up to 1900°F, making it ideal for harsh acid exposures.

What is the chemical composition of Hastelloy C-276?

Typically, it includes Ni (balance), Mo 15-17%, Cr 14.5-16.5%, Fe 4-7%, W 3-4.5%, with low carbon to prevent grain boundary precipitation.

How does Hastelloy C-276 perform in oxidizing and reducing acid environments?

It excels in resisting corrosion from acids like sulfuric, hydrochloric, and phosphoric, handling both oxidizing media like nitric acid and reducing ones like hydrogen chloride.

What are common applications for Hastelloy C-276 strip?

It's used in chemical processing for reactors, heat exchangers, and piping, as well as in pollution control, petrochemicals, and pharmaceutical equipment exposed to aggressive acids.

What role does Hastelloy C-276 play in chemical processing?

In chemical plants, it protects against corrosive halides, organic chlorides, and acid mixtures in processes like chloride-based reactions and distillation columns.

What are the industry trends for Hastelloy C-276 in 2025?

The market is growing at a CAGR of 4-14%, driven by demand in chemical, oil & gas, and sustainable processing sectors, with focus on high-performance alloys for eco-friendly applications.

How is Hastelloy C-276 strip maintained for optimal performance?

Regular cleaning to remove deposits, avoiding high-temperature exposures that cause precipitation, and using proper welding techniques ensure long-term corrosion resistance.