Stable Thermal-Resistant Hastelloy C-4 Strip for High-Temperature Welded Chemical Applications

At DLX, we're all about delivering the best in stable thermal-resistant Hastelloy C-4 strip for those tough high-temperature welded chemical applications. If you're hunting for reliable Hastelloy C-4 strip suppliers who get the job done right, stick around as we break down why our UNS N06455 strip is your go-to choice. Our Hastelloy C-4 strip is a nickel-chromium-molybdenum alloy that's designed to handle the heat and the harsh stuff without flinching. With UNS N06455 marking its top-tier status, this material brings exceptional thermal stability and corrosion resistance to the table. Picture a strip that stays solid in scorching temps while fending off aggressive chemicals—that's the magic we bring at DLX. The makeup includes a hefty dose of nickel at around 65-70% for that robust foundation, 14-18% chromium to battle oxidation, 14-17% molybdenum for pitting and crevice defense, and just a touch of titanium up to 0.7% to enhance stability. We keep iron under 3% to avoid any vulnerabilities, and add in small amounts of manganese, silicon, and carbon for that perfect balance. This isn't your average alloy; it's a high-performer in reducing and oxidizing environments alike. Here at DLX, we source premium raw materials to craft Hastelloy C-4 strip that complies with standards like ASTM B575 and ASME SB575. Available in thicknesses from 0.05mm to 3mm and widths up to 600mm, it's ready for whatever fabrication you throw at it—annealed for easy bending or cold-rolled for extra toughness.

For more details, pls directly contact us.

Shifting gears to the bigger picture, the industry around stable thermal-resistant Hastelloy C-4 strip is heating up, no pun intended. The chemical processing sector is expanding fast, with projections showing over 4% annual growth through 2030, thanks to rising demand for specialty chemicals and advanced manufacturing. High-temperature applications are key here, especially in oil and gas where exploration pushes materials to their limits. Pollution control is another big driver—think flue gas desulfurization systems that need alloys tough enough for hot, corrosive gases. In pharmaceuticals, the need for pure, uncontaminated processes is ramping up with biopharma innovations. Trends point to a push for materials that offer longevity and reduce environmental impact, aligning with global sustainability goals. Stricter regulations on emissions and safety are forcing companies to upgrade to alloys like Hastelloy C-4 strip that minimize leaks and failures. At DLX, we're riding this wave by refining our production to meet these demands, serving clients across North America, Europe, and Asia who want thermal-resistant solutions for welded setups. The market's shift toward green tech means more focus on durable materials that cut down on waste and energy use, and our UNS N06455 strip fits right in.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

On the application side, our stable thermal-resistant Hastelloy C-4 strip excels in high-temperature welded chemical scenarios. In chemical plants, it's perfect for reactors and heat exchangers where welding is constant, and temps soar—resisting stress corrosion cracking like a champ. We've supplied it for systems handling sulfuric acid, phosphoric acid, and even nitric acid mixtures without a hitch. Its ability to stay microstructure-stable during welding means no weak spots post-fabrication, which is crucial in high-pressure pipes for oil and gas. Pollution control apps love it too, like in scrubbers dealing with hot chlorine or sulfur compounds. For pharmaceuticals, it keeps things sterile in welded vessels exposed to aggressive cleaners and heat cycles. Beyond that, it's a staple in waste incinerators and aerospace-related chemical handling where thermal shocks are common. At DLX, we tailor our Hastelloy C-4 strip for these uses, ensuring it thrives from -200°C to 1038°C and in pH extremes. This versatility helps engineers tackle projects that demand reliability under fire—literally.

What really puts DLX ahead when you compare our approach? Sure, there are other options out there for thermal-resistant alloys, but our dedication to quality in Hastelloy C-4 strip gives us that unbeatable edge. We don't cut corners; instead, we use state-of-the-art vacuum melting and precise rolling to produce strips with uniform grain structure, free from defects that could cause failures. This leads to longer-lasting performance in your welded applications, saving you big on repairs. While some might overlook thorough testing, we put every batch through ultrasonic inspections, corrosion simulations, and thermal cycling tests to guarantee top-notch results. We're big on sustainability, incorporating recycled materials where it boosts eco-friendliness without skimping on strength—ideal for clients in chemical sectors aiming for greener ops. Our logistics are dialed in for fast turnaround, whether it's a small order for testing or bulk for full-scale production. And our experts are always ready to chat about optimizing your setup, from welding tips to custom dimensions. In an industry where heat and corrosion can shut things down fast, going with DLX means choosing peace of mind and efficiency.

Let's get into the nitty-gritty of why our stable thermal-resistant Hastelloy C-4 strip stands out metallurgically. Its low carbon and silicon levels prevent carbide precipitation during heating, so welding doesn't compromise its integrity—unlike materials that sensitize and crack. This is a game-changer in high-temperature chemical applications where downtime equals lost revenue. With a PREN around 40-45, it outperforms in pitting resistance, especially in chloride-heavy environments. We've fine-tuned the surface to minimize crevices, adding extra protection. Industry trends like digital twins in manufacturing are influencing how we develop products, and at DLX, we're using data analytics to predict performance in real-world scenarios. The chemical industry's projected $5 trillion value by 2025 underscores the need for alloys like UNS N06455 strip that support scalable, safe operations. We're not just suppliers; we're partners in innovation, working with clients to push boundaries in welded designs.

Exploring more applications, our Hastelloy C-4 strip shines in high-pressure systems for petrochemicals, where it handles hot acids without degrading. In pollution control, it's used in hot gas filters and ducts, resisting oxidation at elevated temps. Pharmaceutical welded lines benefit from its non-contaminating nature during sterilization. We've seen it in marine chemical transport too, though its real forte is land-based high-heat processes. The thread running through? Exceptional stability that lets you focus on production, not problems. Trends toward automation in chemical plants favor materials like our strip that integrate seamlessly with robotic welding.

Comparison Parameters Table

| Parameter | Hastelloy C-4 (UNS N06455) Strip | Similar Nickel-Based Alloy (e.g., Higher Cr Variant) | Standard Stainless Steel (e.g., 316L Type) |

|---|---|---|---|

| Chemical Composition | Ni: 65-70%, Cr: 14-18%, Mo: 14-17%, Ti: ≤0.7%, Fe: ≤3% | Ni: 57%, Cr: 22%, Mo: 13%, W: 3%, Fe: 3% | Fe: Balance, Cr: 16-18%, Ni: 10-14%, Mo: 2-3% |

| Density (g/cm³) | 8.64 | 8.69 | 8.00 |

| Tensile Strength (MPa) | 690 (min) | 690 (min) | 485 (min) |

| Yield Strength (MPa) | 310 (min) | 310 (min) | 170 (min) |

| Elongation (%) | 40 (min) | 45 (min) | 40 (min) |

| Pitting Resistance Equivalent Number (PREN) | 40-45 | 45-50 | 25-30 |

| Corrosion Resistance | Superior in high-temperature acids and welded zones, excellent in reducing/oxidizing media | Versatile in mixed acids, but less stable at extreme heat | Adequate in mild environments, fails in acids and heat |

| Temperature Range (°C) | -200 to 1038 (service) | -200 to 400 | -200 to 800 (but degrades quickly) |

| Weldability | Outstanding, no sensitization | Excellent, minimal issues | Good, but risks intergranular attack |

| Typical Applications | High-temp chemical processing, welded reactors, pollution control | Marine, pharma, general chemicals | Food processing, basic piping |

| Cost Efficiency | Moderate initial, high long-term savings from durability | Similar, but may require more oversight | Low initial, frequent replacements needed |

When stacking up DLX's methods against the norm, our advantages pop. We prioritize customization—while others might push standard rolls, we adjust alloy tweaks and finishes to match your exact needs, cutting material waste and boosting fit. Our pricing is straightforward, reflecting the value of a strip that endures longer in thermal stress. Global sourcing ensures consistent supply, even amid shortages. We back it with comprehensive certs like ISO 9001, giving you the paperwork edge in regulated fields. Our R&D keeps evolving the product, like enhancing ductility for complex bends in welded assemblies.

As trends evolve, things like AI in quality control are transforming how we make Hastelloy C-4 strip at DLX—spotting issues before they arise for flawless output. The drive for low-emission chemical processes boosts demand for resistant materials, and our thermal-stable options help meet IMO and EPA standards. In oil and gas, with deeper drilling, high-temp alloys are essential. We're scaled to handle it all, from prototypes to mass runs.

For more details, pls directly contact us.

About Us:

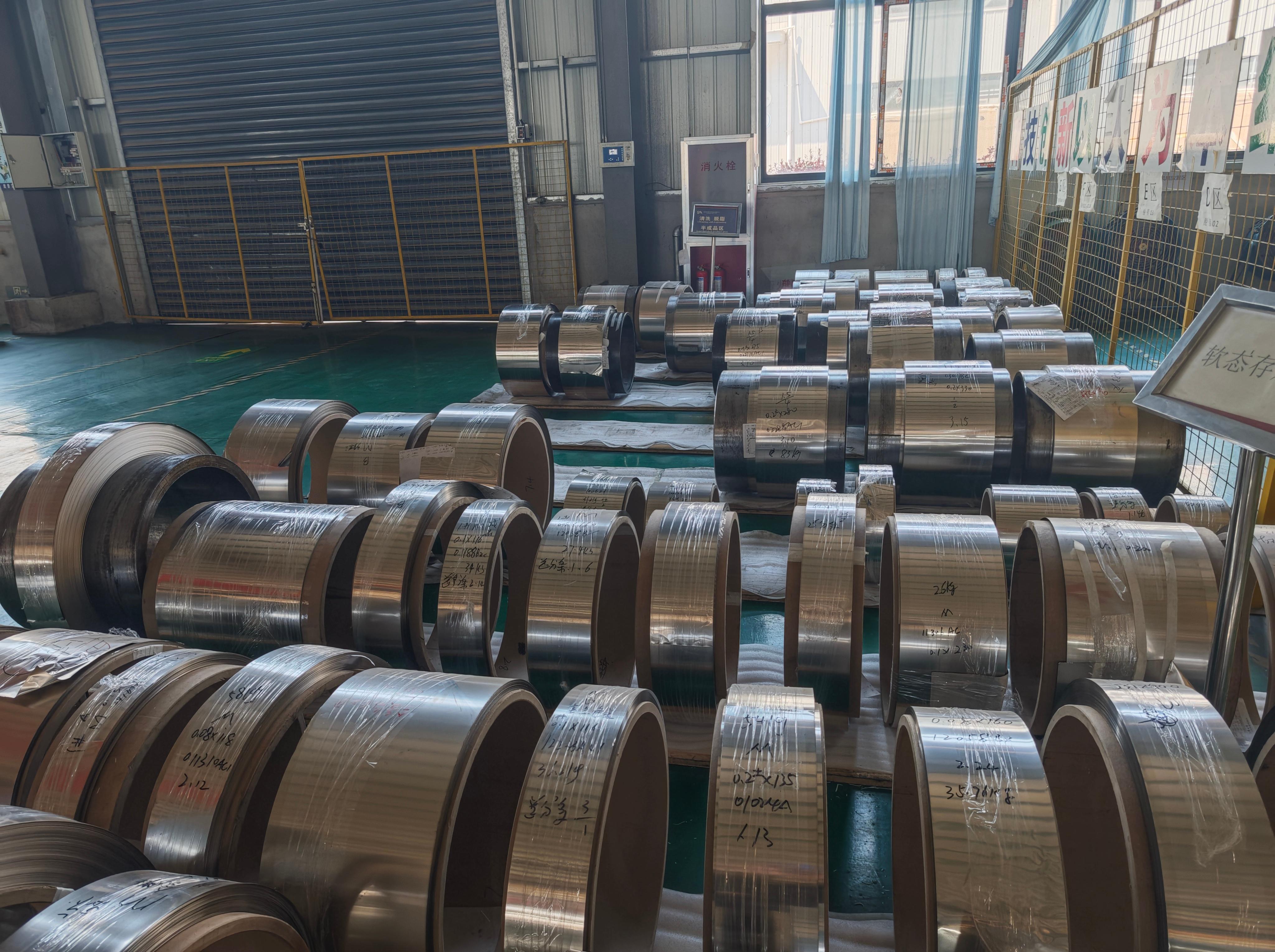

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of Hastelloy C-4 alloy?

Hastelloy C-4 (UNS N06455) consists primarily of nickel (balance, around 65-70%), chromium (14-18%), molybdenum (14-17%), with low iron (up to 3%), titanium (up to 0.7%), and trace elements like manganese, silicon, carbon, phosphorus, and sulfur.

What types of corrosion does Hastelloy C-4 resist?

It provides outstanding resistance to pitting, crevice corrosion, stress corrosion cracking, intergranular corrosion, and general corrosion in both oxidizing and reducing acids, including sulfuric, phosphoric, nitric, and hydrochloric acids.

What are the key applications for Hastelloy C-4 strip in high-temperature environments?

It's used in chemical reactors, heat exchangers, and piping systems where it maintains stability during welding and exposure to temperatures up to 1038°C.

How does Hastelloy C-4 perform in welded chemical applications?

Its microstructural stability prevents sensitization during welding, ensuring strong joints that resist cracking and corrosion in aggressive chemical processes.

What mechanical properties make Hastelloy C-4 strip thermally resistant?

It features high ductility, tensile strength around 690 MPa, yield strength of about 310 MPa, elongation up to 40%, and excellent thermal stability without precipitation hardening.

What industry trends are boosting demand for Hastelloy C-4?

Increasing focus on high-temperature chemical processing, stricter safety regulations in oil and gas, and the shift toward sustainable, long-lasting materials in pollution control and pharmaceuticals.

Can Hastelloy C-4 strip be easily welded and fabricated?

Yes, its weldability is superior due to low carbon and silicon content, allowing for forming, bending, and welding without loss of corrosion resistance or structural integrity.

How does Hastelloy C-4 contribute to efficiency in chemical industries?

Its thermal resistance and corrosion protection minimize downtime, extend equipment life, and reduce maintenance costs in high-heat, corrosive settings.