High-Performance Hastelloy C276 UNS N10276 Strip for Oxidizing and Reducing Acid Environments

At DLX, we're all about delivering top-tier solutions for industries facing tough corrosive challenges, and our High-Performance Hastelloy C276 UNS N10276 Strip is a prime example of that commitment. This strip is crafted from one of the most reliable alloys out there, designed specifically for environments where oxidizing and reducing acids are a constant threat. Whether you're dealing with sulfuric acid in a processing plant or hydrochloric acid in petrochemical operations, this material holds up where others falter. We've engineered it to provide unmatched durability, helping you cut down on downtime and maintenance costs. It's not just a strip; it's a safeguard for your equipment in the harshest conditions.

For more details, pls directly contact us.

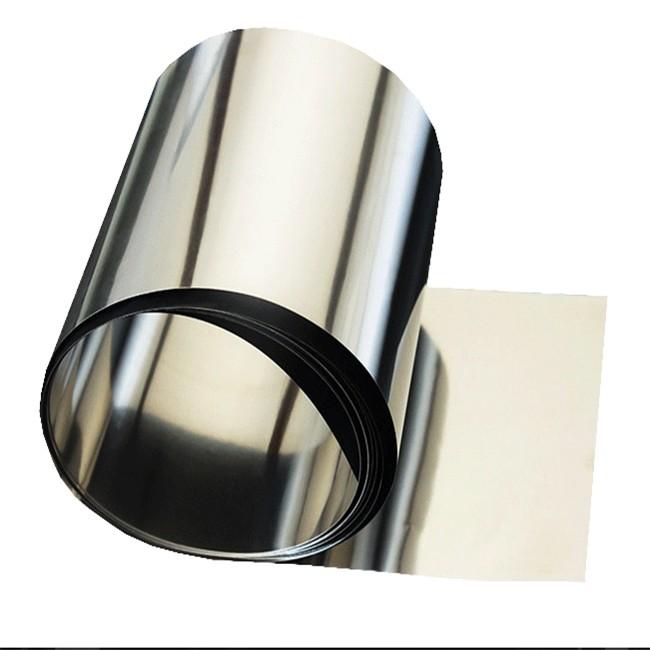

Diving into what makes our Hastelloy C276 strip stand out, let's start with its core makeup. As UNS N10276, it's a nickel-based alloy packed with molybdenum, chromium, and tungsten. The nickel base gives it that ductility and ease of forming, while the high molybdenum content—around 15-17%—kicks in for stellar resistance against reducing acids like hydrogen chloride. Chromium at 14.5-16.5% handles the oxidizing side, tackling things like nitric acid mixtures without breaking a sweat. Add in tungsten for extra pitting resistance, and you've got a powerhouse that laughs off stress corrosion cracking. At DLX, we roll this into precision strips with thicknesses from 0.05mm to 3mm, widths up to 600mm, and customizable lengths. Our process includes advanced annealing for better workability, ensuring you can bend, weld, and fabricate without issues. Plus, it maintains its properties up to 1900°F, making it perfect for high-temp acid exposures.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Shifting to the bigger picture, the industry around corrosion-resistant alloys like Hastelloy C276 is buzzing in 2025. Market forecasts show steady growth, with the global Hastelloy market expected to hit around $1.8-2 billion by 2033, growing at a CAGR of 4-5.5%. What's fueling this? For starters, the chemical processing sector is expanding rapidly, driven by demand for pharmaceuticals, fertilizers, and specialty chemicals. With stricter environmental regulations worldwide, companies are investing in materials that can handle aggressive acids without leaching or failing, reducing pollution risks. Oil and gas exploration, especially in sour environments with hydrogen sulfide, is another big driver—Hastelloy C276 strips are key in downhole tools and pipelines where acid gases are prevalent. Sustainability is huge too; as industries push for net-zero emissions by 2050, efficient acid-handling systems cut energy waste and extend equipment life. We've seen a surge in Asia-Pacific markets, where industrial growth is booming, and North America focusing on infrastructure upgrades. Raw material prices for nickel and molybdenum fluctuate, but at DLX, we lock in supplies to keep costs stable for our clients. Overall, trends point to more integration with smart tech, like IoT for real-time corrosion monitoring, making high-performance strips like ours even more valuable.

When it comes to applications, our High-Performance Hastelloy C276 UNS N10276 Strip shines in oxidizing and reducing acid environments across multiple sectors. In chemical processing, it's a go-to for reactors and evaporators dealing with mixed acids—think phosphoric acid production where both oxidizing impurities and reducing conditions coexist. Our strip lines vessels and piping, preventing leaks that could halt operations. We've supplied it for acetic anhydride plants, where it resists hot contaminated acids better than standard materials. In petrochemicals, it's used in chloride processes, handling organic halides without pitting. For pollution control, it excels in scrubbers exposed to moist chlorine or hypochlorite, scrubbing out acids from flue gases efficiently. Pharmaceutical manufacturing benefits too, with strips in equipment for acid-based synthesis, ensuring purity and compliance with FDA standards. Even in waste treatment, it handles acidic slurries in tanks and pumps, extending service life amid corrosive organics. Clients report up to 40% longer lifespan compared to alternatives, translating to real savings in harsh acid setups.

Comparing what we do at DLX to general market offerings, our advantages are pretty clear without pointing fingers. A lot of suppliers skimp on quality checks, leading to batches with inconsistent composition that fail prematurely in acid environments. We test every roll for uniformity, using ultrasonic and corrosion simulations to guarantee performance. Our customization goes beyond basics—we offer tailored annealing and finishes, like bright or pickled surfaces, which ease fabrication and reduce acid buildup. While some providers rely on overseas sourcing with long lead times and quality risks, our domestic production means faster delivery, often within weeks, helping you meet tight deadlines. Cost-wise, we focus on value over cheap upfront prices; our strips' superior resistance means fewer replacements, lowering your total costs over time. We've had feedback where generic options cracked under stress in reducing acids after months, but ours hold strong for years. Sustainability is baked in too—we recycle alloy scraps and use energy-efficient mills, aligning with green trends that others might ignore.

Comparison Parameters Table for Hastelloy C-276 vs. 316L Stainless Steel

| Parameter | Hastelloy C-276 | 316L Stainless Steel |

|---|---|---|

| Chemical Composition | Ni: Balance, Mo: 15-17%, Cr: 14.5-16.5%, Fe: 4-7%, W: 3-4.5% | Ni: 10-14%, Cr: 16-18%, Mo: 2-3%, Fe: Balance, C: ≤0.03% |

| Corrosion Resistance | Superior in pitting, crevice, and stress cracking; resists strong acids like HCl and H2SO4 in oxidizing/reducing environments | Good in mild corrosives; vulnerable to chlorides and acids at higher concentrations |

| Temperature Range | Up to 1900°F (1038°C) with excellent oxidation resistance | Up to 1600°F (871°C); susceptible to scaling and embrittlement |

| Tensile Strength (ksi) | 100-120 (room temp) | 70-90 (room temp) |

| Yield Strength (ksi) | 45-60 | 25-40 |

| Elongation (%) | 40-50 | 40-50 |

| Density (g/cm³) | 8.89 | 8.0 |

| Applications Suitability | High for severe acid environments in chemical processing | Moderate for general use; limited in aggressive acids |

| Weldability | Excellent, resistant to grain boundary issues | Good, but prone to sensitization in heat-affected zones |

Digging deeper into industry analysis, 2025 marks a shift toward more resilient materials amid global challenges. With chemical output projected to rise 3-4% annually, driven by EV battery production and renewable fuels, alloys like Hastelloy C276 are critical for safe acid handling. Regulations like the EU's REACH and U.S. Clean Air Act demand better corrosion control to minimize emissions, boosting demand for strips in acid scrubbers and reactors. Emerging markets in India and China are ramping up petrochemical capacities, where reducing acid resistance is key to avoiding shutdowns. Supply chain disruptions from geopolitical tensions highlight the need for reliable sources— that's where DLX steps in with stockpiled inventory. Market reports note a 14% CAGR in specific segments like Hastelloy C276 tubes and strips, thanks to their versatility in hybrid acid environments. Challenges include volatility in molybdenum prices, up 3-5% this year, but we mitigate that through strategic partnerships.

On the application front, let's get specific. In an oxidizing acid setup like nitric acid concentration, our strip prevents intergranular attacks that weaken joints. For reducing acids, such as hydrofluoric acid handling, its tungsten boost enhances resistance to localized corrosion. We've customized strips for hybrid systems in fertilizer plants, where urea synthesis involves both acid types—our low-carbon formula avoids weld decay. In oil refining, it's used in desulfurization units facing sulfuric acid at high temps. Power generation sees it in geothermal plants with acidic brines, maintaining efficiency. Our clients in pulp and paper use it for bleach towers with chlorine dioxide, a strong oxidizer. The strip's mechanical stats—tensile strength of 100-120 ksi—ensure it withstands pressures without deforming, even in vibrating acid lines.

What sets DLX apart further is our hands-on support. Unlike suppliers who just ship and forget, we offer engineering consults to match strip specs to your acid pH, temperatures, and flow rates. Our R&D tweaks processes for tighter tolerances, like ±0.01mm thickness control, improving fit in precision assemblies. In a market where delays cost fortunes, our logistics ensure on-time delivery without tariffs hiking prices. Eco-wise, our low-waste production supports your sustainability goals, something not all providers prioritize. Customers see ROI quickly, often within a year, through reduced acid-related failures.

To wrap the product details, our High-Performance Hastelloy C276 UNS N10276 Strip comes compliant with ASTM B575, in coils or cut lengths, with options for enhanced surface treatments. It's versatile for forming into gaskets or linings, holding up in dynamic acid flows.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Hastelloy C-276 UNS N10276?

Hastelloy C-276 UNS N10276 is a nickel-molybdenum-chromium-tungsten alloy known for its exceptional corrosion resistance in severe environments, including both oxidizing and reducing acids.

What are the key material properties of Hastelloy C-276 strip?

It features high resistance to pitting, crevice corrosion, and stress corrosion cracking, with excellent weldability and stability up to 1900°F, making it ideal for harsh acid exposures.

What is the chemical composition of Hastelloy C-276?

Typically, it includes Ni (balance), Mo 15-17%, Cr 14.5-16.5%, Fe 4-7%, W 3-4.5%, with low carbon to prevent grain boundary precipitation.

How does Hastelloy C-276 perform in oxidizing and reducing acid environments?

It excels in resisting corrosion from acids like sulfuric, hydrochloric, and phosphoric, handling both oxidizing media like nitric acid and reducing ones like hydrogen chloride.

What are common applications for Hastelloy C-276 strip?

It's used in chemical processing for reactors, heat exchangers, and piping, as well as in pollution control, petrochemicals, and pharmaceutical equipment exposed to aggressive acids.

What role does Hastelloy C-276 play in chemical processing?

In chemical plants, it protects against corrosive halides, organic chlorides, and acid mixtures in processes like chloride-based reactions and distillation columns.

What are the industry trends for Hastelloy C-276 in 2025?

The market is growing at a CAGR of 4-14%, driven by demand in chemical, oil & gas, and sustainable processing sectors, with focus on high-performance alloys for eco-friendly applications.

How is Hastelloy C-276 strip maintained for optimal performance?

Regular cleaning to remove deposits, avoiding high-temperature exposures that cause precipitation, and using proper welding techniques ensure long-term corrosion resistance.