Durable Incoloy 800 Bar for Corrosion-Resistant Industrial Components

First off, our Incoloy 800 bar is crafted from a nickel-iron-chromium alloy that's designed to handle extreme heat and corrosive conditions without breaking a sweat. Think of it as the workhorse for your industrial setups. The composition includes about 30-35% nickel, 19-23% chromium, and a hefty dose of iron, plus small amounts of aluminum and titanium that boost its strength. This mix gives our Incoloy 800 bar excellent resistance to oxidation and carburization, meaning it won't degrade quickly even when exposed to high temperatures up to 1100°F. For corrosion-resistant industrial components, this bar is ideal because it forms a protective layer that shields against harsh chemicals and gases. We ensure every Incoloy 800 bar we produce meets strict standards, so you get consistent performance every time.

When it comes to the industry landscape, things are heating up—literally. The demand for high-temperature alloys like Incoloy 800 bar is on the rise in 2025, driven by growth in sectors like petrochemical processing and renewable energy. With global pushes toward cleaner power sources, such as hydrogen production and advanced nuclear reactors, materials that can withstand intense conditions are more crucial than ever. Industry reports show that the superalloy market is expected to grow at a steady pace, with a focus on sustainable manufacturing. Our Incoloy 800 bar fits right into this trend because it's not just durable but also cost-effective compared to some pricier options out there. We've seen a shift where companies are prioritizing alloys that reduce downtime and maintenance costs, and that's where our corrosion-resistant Incoloy 800 bar shines. In petrochemical plants, for instance, the need for reliable components in reforming processes is booming, and our bar helps meet those demands without compromising on safety or efficiency.

For more details, pls directly contact us.

Now, let's talk applications because that's where our Incoloy 800 bar really proves its worth. In the chemical industry, it's used for heat exchangers and piping systems that deal with nitric acid or other aggressive media. The corrosion resistance prevents cracking and leaks, keeping operations smooth. For power generation, our Incoloy 800 bar goes into steam superheating tubing and high-temperature heat exchangers, especially in gas-cooled nuclear setups. It handles the heat without losing structural integrity, which is key for long-term reliability. In heat-treating furnaces, you'll find it in radiant tubes, muffles, and fixtures—places where constant exposure to high temps could wear out lesser materials. Even in aerospace and paper pulp production, our bar supports components like digester heaters and effluent coolers. What ties all these together is the bar's ability to maintain strength and resist embrittlement, making it a go-to for corrosion-resistant industrial components across the board.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

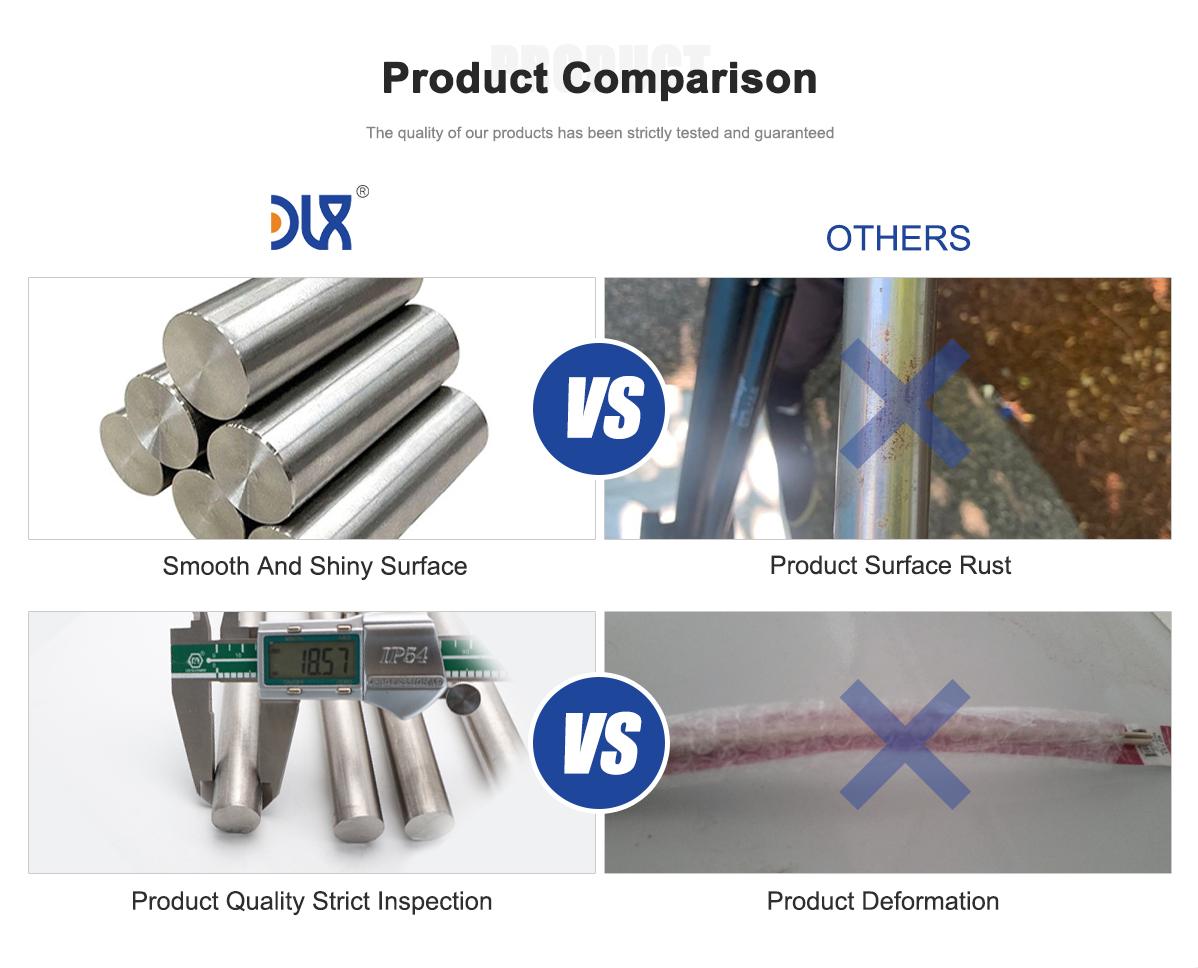

Compared to what some other suppliers offer, our approach gives us a clear edge. While many focus on basic production, we invest in advanced annealing processes that ensure our Incoloy 800 bar has superior grain structure for better creep resistance. This means our bars last longer in service, reducing your replacement frequency and overall costs. We also prioritize customization—whether you need specific diameters from 3mm to 600mm or lengths up to 6 meters, we tailor it to your specs without skimping on quality. Our testing protocols are rigorous, checking for tensile strength, hardness, and corrosion rates to guarantee every piece performs as promised. Unlike generic options that might cut corners on alloy purity, our Incoloy 800 bar uses high-grade raw materials, resulting in better oxidation resistance and fewer failures in the field. Customers tell us this reliability translates to real savings, especially in downtime-sensitive industries.

Diving deeper into why our Incoloy 800 bar excels, consider the mechanical side. With a tensile strength of 75-85 ksi and yield around 30-40 ksi, it holds up under stress without deforming easily. Add in elongation of 30-43%, and you've got a material that's tough yet flexible enough for forming into bars or rods. In high-temp scenarios, it resists creep—the slow deformation under load—which is vital for components like furnace retorts. Our production ensures these properties are optimized, so your corrosion-resistant industrial components don't just meet but exceed expectations. We've had clients in petrochemicals report extended service life, attributing it to our bar's consistent performance.

On the corrosion front, our Incoloy 800 bar is a standout. The high chromium content creates a stable oxide film that blocks oxygen and carbon ingress, preventing scaling even at 1800°F. In sulfidizing atmospheres, it holds its own with minimal weight loss, as shown in lab tests. For chloride-heavy environments, the nickel helps avoid stress-corrosion cracking, a common issue in lesser alloys. We enhance this through precise heat treatments, making our bar more resilient than standard offerings. If you're building industrial components that face mixed corrosives, our Incoloy 800 bar provides that extra layer of protection.

Looking at industry analysis more closely, the superalloy sector is evolving with tech advancements. In 2025, we're seeing more integration of AI in material design, predicting alloy behavior under stress. This aligns with our R&D efforts, where we simulate real-world conditions to refine our Incoloy 800 bar. Trends also point to eco-friendly production, like recycling nickel scraps to cut emissions—something we incorporate to make our bars sustainable. The global market for corrosion-resistant materials is projected to expand, especially in Asia-Pacific with rising industrialization. Our strategic sourcing keeps costs competitive, allowing us to offer premium Incoloy 800 bar without premium prices.

In applications like ethylene production, our bar forms cracking tubes and pigtails that endure thermal cycling. The stability prevents leaks, ensuring safe operations. For vinyl chloride plants, it's in return bends and flanges, resisting the aggressive chemistry. In power plants, it supports ammonia coolers and superheaters, contributing to efficient energy output. Our clients in these fields appreciate how our bar integrates seamlessly, often outperforming expectations in longevity.

Comparison Parameters Table

| Property | Incoloy 800 | Incoloy 800H | Incoloy 800HT |

|---|---|---|---|

| UNS Designation | N08800 | N08810 | N08811 |

| Carbon Content (%) | 0.10 max | 0.05-0.10 | 0.06-0.10 |

| Al + Ti Content (%) | 0.30-1.20 | 0.30-1.20 | 0.85-1.20 |

| Tensile Strength (ksi) | 75-85 (annealed) | 65-80 (solution heat-treated) | 65-80 (solution heat-treated) |

| Yield Strength (ksi) | 30-40 (annealed) | 25-35 (solution heat-treated) | 25-35 (solution heat-treated) |

| Elongation (%) | 30-43 | 30-47 | 30-47 |

| Max Service Temp (°F) | Up to 1100 (general use) | Above 1100 (creep-resistant) | Above 1100 (optimum high-temp) |

| Creep/Rupture Strength | Moderate at elevated temps | Higher than 800 | Highest among variants |

| Grain Size (ASTM) | Not specified | 5 or coarser | 5 or coarser |

| Oxidation Resistance | Excellent up to 1800°F | Similar to 800, enhanced stability | Similar to 800, enhanced stability |

| Typical Applications | Heat exchangers, piping | Reforming tubing, furnace parts | High-temp heaters, nuclear tubing |

What sets us apart in company comparisons is our customer-centric model. While others might ship and forget, we provide ongoing support, from material selection to post-installation advice. Our inventory is robust, with quick turnaround times—often faster than industry averages. We avoid common pitfalls like inconsistent hardness by using state-of-the-art rolling mills, resulting in bars with uniform properties. Feedback highlights our superior surface finish, reducing fabrication issues. In essence, choosing our Incoloy 800 bar means partnering with a team dedicated to your success.

Expanding on product intro, our durable Incoloy 800 bar comes in various forms—round, hex, square—to fit your needs. We stock sizes that cater to small prototypes or large-scale projects, all certified to ASTM specs. The alloy's low work-hardening rate makes it easy to machine, saving you time in production. For corrosion-resistant industrial components, this versatility is a game-changer.

Industry-wise, challenges like supply chain disruptions are being tackled with localized manufacturing, which we embrace to ensure steady supply of Incoloy 800 bar. Trends toward lightweight yet strong materials favor our alloy's density of 0.287 lb/in³, balancing performance and weight.

In nuclear applications, our bar's resistance to nitriding and low sigma phase formation keeps reactors running safely. For aerospace, it's in high-temp fasteners, where reliability is non-negotiable.

About Us:

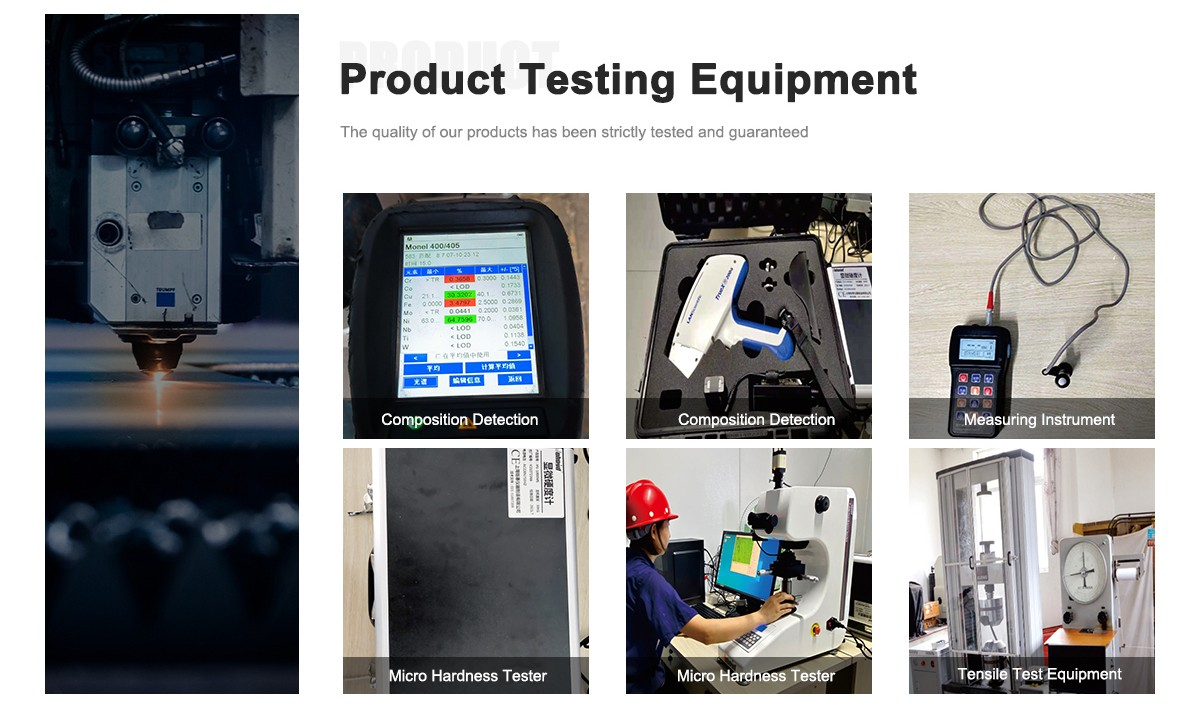

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is the chemical composition of Incoloy 800 bar?Incoloy 800 bar typically consists of 30-35% nickel, 19-23% chromium, a minimum of 39.5% iron, up to 0.10% carbon, 0.15-0.60% aluminum, 0.15-0.60% titanium, and trace amounts of manganese, sulfur, silicon, and copper.

2. What are the key mechanical properties of Incoloy 800 bar?Incoloy 800 bar offers a tensile strength of around 75-85 ksi, yield strength of 30-40 ksi, elongation of 30-43%, and maintains strength up to 1500°F with good creep and rupture resistance.

3. How does Incoloy 800 bar resist corrosion?Incoloy 800 bar provides excellent resistance to oxidation, carburization, sulfidation, and chloride stress-corrosion cracking due to its high nickel and chromium content, forming a protective oxide layer in harsh environments.

4. What industries commonly use Incoloy 800 bar?Incoloy 800 bar is widely used in petrochemical processing, power generation, nuclear plants, heat-treating equipment, and chemical industries for components requiring high-temperature durability.

5. What are typical applications for Incoloy 800 bar?Common applications include heat exchangers, furnace fixtures, piping systems, steam superheating tubing, catalyst tubing, and retorts in high-temperature and corrosive settings.

6. What industry trends are influencing the use of Incoloy 800 bar in 2025?In 2025, trends focus on sustainable energy with increased demand in renewable power and hydrogen production, alongside advancements in alloy processing for better efficiency in extreme conditions.

7. How does temperature affect the performance of Incoloy 800 bar?Incoloy 800 bar performs optimally up to 1100°F for general use, with reduced strength at higher temperatures, making variants like 800H/800HT better for applications above 1100°F.

8. What makes Incoloy 800 bar suitable for long-term industrial use?Its combination of moderate strength, resistance to embrittlement, and cost-effectiveness ensures reliability in prolonged exposure to heat and corrosion, reducing maintenance needs in industrial setups.