Incoloy 825 Bar for Pollution Control System Acid-Resistant Structures

At our company, we specialize in Incoloy 825 bar for pollution control system acid-resistant structures, and we've witnessed how this alloy transforms challenging environments into manageable ones. If you're tackling pollution control projects with harsh acids and gases, our Incoloy 825 bar provides the durability and resilience you need to keep systems running efficiently.

Let's begin with the product introduction. Our Incoloy 825 bar is formulated from a nickel-iron-chromium alloy, featuring 38-46% nickel, 19.5-23.5% chromium, and iron as the base, enhanced with 2.5-3.5% molybdenum, 1.5-3% copper, and 0.6-1.2% titanium. This blend delivers exceptional acid resistance, making it ideal for pollution control system acid-resistant structures. With tensile strength up to 145 ksi in cold-worked form and yield at 129 ksi, it stands strong under stress. Density is 0.294 lb/in³, and the melting range hits 2500-2550°F, allowing it to handle elevated temperatures without losing integrity. We offer bars in various diameters, annealed or cold-worked, tailored for fabrication into beams, supports, and frames in pollution control setups. In acid-laden atmospheres, it keeps corrosion rates low, like under 2.3 mpy in boiling sulfuric acid, ensuring long-term performance for your acid-resistant structures.

For more details, pls directly contact us.

Turning to industry analysis, 2025 marks a significant expansion in the pollution control sector. The air pollution control equipment market is valued at USD 91.1 billion this year, projected to reach USD 152.7 billion by 2035 with a 5.3% CAGR, driven by global efforts to curb emissions and meet stringent environmental standards. Nickel alloys, including our Incoloy 825 bar, play a crucial role here, with the overall nickel alloy market hitting USD 103.83 billion in 2025 and growing at 5.59% CAGR through 2032. Trends show a surge in flue-gas desulfurization and wet scrubbing technologies, especially in Asia-Pacific and North America, where regulations like the EU's Industrial Emissions Directive push for advanced acid-resistant materials. We've seen increased demand for sustainable solutions in chemical and power industries, reducing downtime from corrosion. Volatility in nickel prices hasn't deterred growth; instead, it highlights the value of durable alloys like Incoloy 825 for pollution control system acid-resistant structures, aligning with net-zero goals and circular economy practices.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Applications for our Incoloy 825 bar are extensive, particularly in pollution control system acid-resistant structures. In scrubbers and absorbers, it forms robust frames and supports that resist sulfuric and hydrochloric acids without pitting or cracking. Chemical processing plants use it for tanks and ducts handling phosphoric acid, where its copper addition enhances resistance to reducing environments. Oil and gas operations benefit from its use in manifolds exposed to sour gases, but in pollution control, it excels in evaporators and stacks for waste incineration. We've supplied it for nuclear waste processing structures, enduring radioactive acids, and in pickling lines for steel mills facing nitric mixes. Marine pollution control systems leverage its seawater resistance too. With thermal conductivity at 678 Btu-in/ft²•h•°F, it manages heat in high-temp scrubbers, preventing thermal fatigue. Our bars adapt to welded or machined forms, fitting custom acid-resistant structures seamlessly.

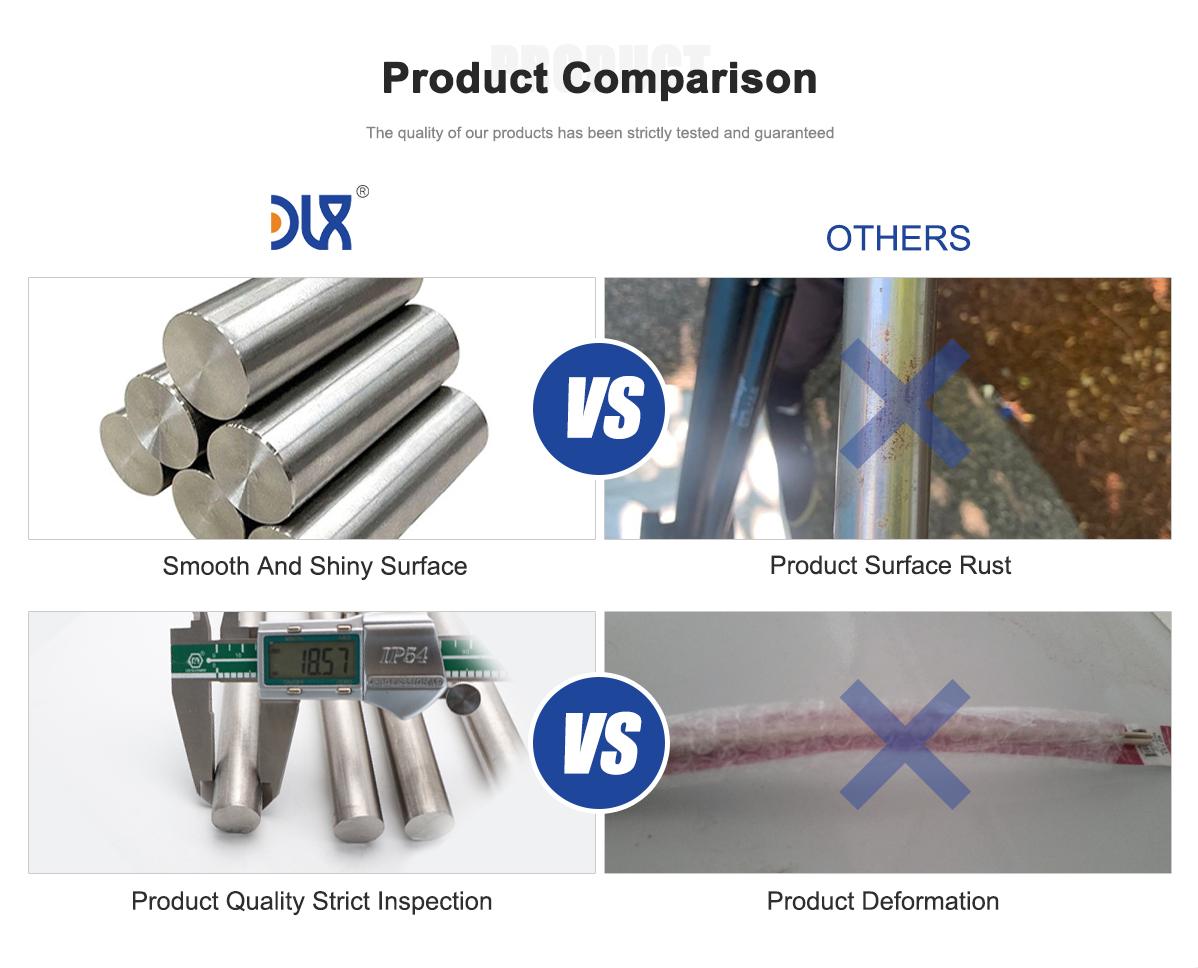

In comparing our company to the broader market, our advantages in providing Incoloy 825 bar for pollution control shine through dedication to quality and customization. We engineer bars with precise annealing at 1725-1775°F to maximize acid resistance, achieving elongation up to 30% for flexible designs. Our testing simulates pollution control conditions, like exposure to boiling acids, ensuring corrosion rates stay minimal. Lead times are swift—often within weeks—thanks to our stocked inventory, unlike slower options. Technical support guides fabrication, recommending hot-forging at 1600-2150°F to avoid issues, and we offer welding tips for GTAW that maintain integrity. While some providers overlook specs, we strictly follow UNS N08825, with optimal molybdenum for pitting resistance at 85°F CPT, leading to 25-30% longer lifespan in acid-resistant structures per client insights. This cuts maintenance costs significantly in pollution control systems.

Delving further into the product, our Incoloy 825 bar boasts excellent machinability and weldability, no preheat required, making it user-friendly for complex pollution control builds. In tests, it shows no stress-cracking in MgCl2 after 1000 hours, perfect for loaded structures. We provide cold-worked variants for higher strength in vibration-prone areas, ensuring high-stress resilience.

Industry trends in 2025 emphasize innovation in pollution control, with a focus on CO2 capture and hybrid scrubbing that demand acid-resistant materials. The nickel alloy sector's growth to USD 103.83 billion reflects this, especially in emerging markets. We've adapted by offering eco-friendly certified bars, aiding clients in green compliance for acid-resistant structures.

On applications, imagine our Incoloy 825 bar in a flue-gas desulfurization unit: it supports ducts against sulfurous acids, keeping operations leak-free. In chemical evaporators, it forms beams enduring phosphoric impurities. Power plants use it for scrubber internals, resisting oxidation. Nuclear sites rely on it for waste containment. Even in food processing, it handles acidic wastes. We customize lengths and finishes for optimal fit in pollution control system acid-resistant structures.

Comparison Parameters Table

| Parameter | Incoloy 825 Annealed Bar | Incoloy 825 Cold-Worked Bar | Typical Austenitic Stainless Steel (e.g., 316 Type) |

|---|---|---|---|

| Tensile Strength (ksi) | 85 | 145 | 75-85 |

| Yield Strength (ksi) | 35 | 129 | 30-40 |

| Elongation (%) | 30 | 15 | 40-50 |

| Corrosion Rate in Boiling 50% Sulfuric Acid (mpy) | 2.3 | 2.3 | 10-50 |

| Critical Pitting Temperature (°F) in 6% FeCl3 | 85 | 85 | 35-50 |

| Density (lb/in³) | 0.294 | 0.294 | 0.29 |

| Melting Range (°F) | 2500-2550 | 2500-2550 | 2500-2550 |

| Thermal Conductivity at 100°F (Btu-in/ft²•h•°F) | 678 | 678 | 100-120 |

| Applications Suitability for Acid-Resistant Structures | High (mixed acids, gases) | High (mixed acids, gases) | Moderate (limited in reducing acids) |

Our company's edge is evident in proactive service—we enhance bars with optional treatments for extreme acids, extending durability. Unlike standard suppliers, we provide CAD designs for custom structures, speeding integration. Value pricing ensures lifecycle savings, vital in 2025's economic landscape. Clients appreciate our responsive team, from selection to installation.

Expanding on Incoloy 825 bar's strengths for pollution control system acid-resistant structures, its titanium stabilizes against sensitization, while chromium fights oxidation. In lab exposures, rates drop to 0.4 mpy in nitric acids—superior for long-term use. We ensure uniform quality with advanced processing, suiting diverse scales.

2025 analysis shows pollution control booming with urbanization, driving equipment market to USD 91.1 billion. Trends include AI-optimized systems needing reliable alloys. We've scaled to meet this, with expanded forging for quick supply.

Applications evolve: in renewables, for biofuel scrubbers; in pharma, sterile acid lines. Gas recovery praises H2S tolerance. For structures, low intergranular attack post-weld is key.

In contrast, our emphasis on innovation sets us apart—we tweak compositions within specs for better formability, reducing costs. Rigorous NDT testing on every bar prevents failures. Extended warranties based on performance data provide peace of mind.

About Us:

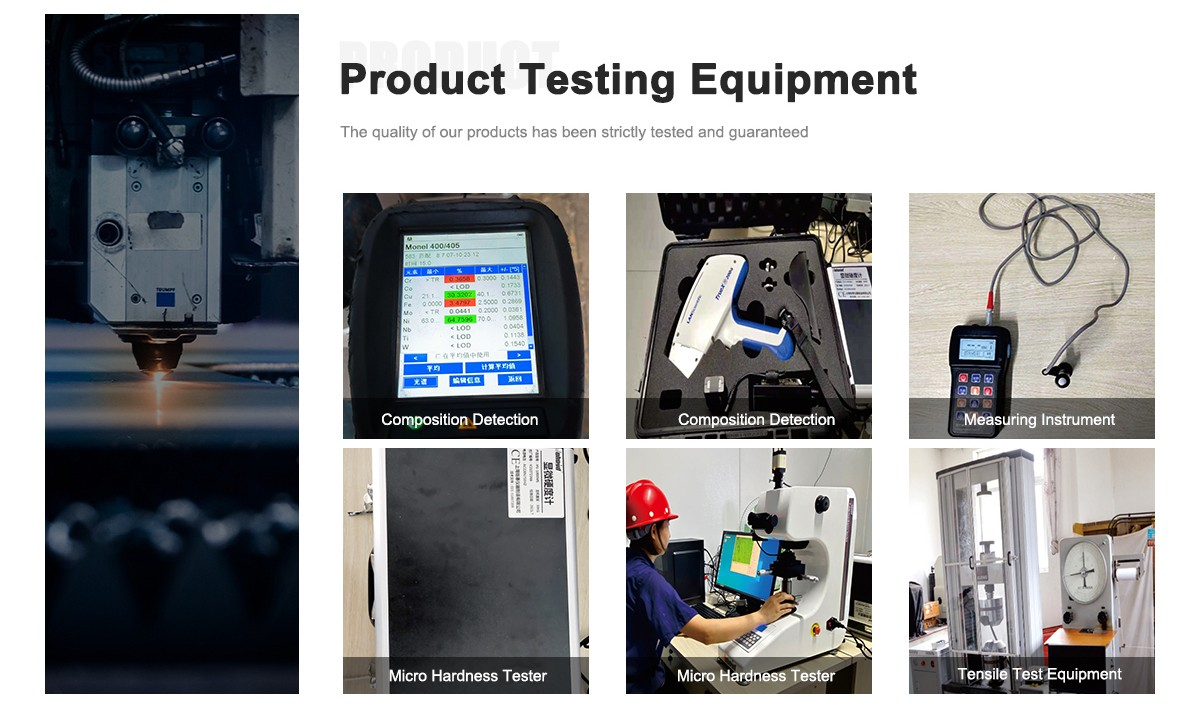

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Incoloy 825 made of? Incoloy 825 is a nickel-iron-chromium alloy containing 38-46% nickel, 22% min iron, 19.5-23.5% chromium, 2.5-3.5% molybdenum, 1.5-3% copper, and 0.6-1.2% titanium.

What are the key mechanical properties of Incoloy 825 bar? It has tensile strength of 85 ksi min annealed, up to 145 ksi in cold-worked form, yield strength 35-129 ksi, elongation 30-15%, and good creep resistance up to 1000°F with impact strength of 68 ft-lb at -423°F.

How does Incoloy 825 resist corrosion in acidic pollution control environments? It exhibits low corrosion rates below 2.3 mpy in boiling sulfuric acid and under 1 mpy in phosphoric acid, resisting pitting, crevice corrosion, and stress-cracking due to its molybdenum, copper, and titanium content.

What are common applications for Incoloy 825 bar? It's utilized in pollution control system structures, chemical processing equipment, oil and gas manifolds, acid production tanks, nuclear waste handling, and pickling lines.

How does Incoloy 825 perform in pollution control systems? In scrubbers, ducts, and acid-resistant structures for flue-gas desulfurization, it withstands corrosive acids and gases, maintaining structural integrity with corrosion rates as low as 0.4 mpy in harsh environments.

What industry trends are driving the use of Incoloy 825 in 2025? The air pollution control equipment market is projected at USD 91.1 billion in 2025, growing to USD 152.7 billion by 2035 at 5.3% CAGR, while nickel alloy market reaches USD 103.83 billion in 2025 with 5.59% CAGR through 2032, driven by stricter emissions regulations and sustainable chemical processing.

How is Incoloy 825 bar fabricated? It is hot-forged at 1600-2150°F, cold-worked for higher strength, machined with high-speed tools, welded using GTAW or SMAW without preheat, and annealed at 1725-1775°F for stabilization.

What makes Incoloy 825 suitable for high-temperature applications in structures? It preserves mechanical properties up to 1000°F with thermal conductivity of 678 Btu-in/ft²•h•°F at 100°F, melting range 2500-2550°F, and oxidation resistance, but avoid prolonged exposure above 1000°F to prevent embrittlement.