High-Strength Incoloy 925 Bar for Harsh Offshore and Chemical Environments

At our company, we're proud to offer high-strength Incoloy 925 bar that's built tough for harsh offshore and chemical environments. If you're scouting for a top Incoloy 925 bar supplier, we've got you covered with materials that deliver real performance where it counts. Our high-strength Incoloy 925 bar stands out because it's designed to handle extreme conditions without letting you down, blending strength and corrosion resistance in one reliable package.

Let's kick off with what makes our high-strength Incoloy 925 bar tick. It's an age-hardenable nickel-iron-chromium alloy, with a composition that includes 42-46% nickel for cracking resistance, 19.5-22.5% chromium to fight oxidation, and additions like 2.5-3.5% molybdenum and 1.5-3% copper for tackling reducing chemicals. Titanium at 1.9-2.4% and aluminum at 0.1-0.5% kick in during heat treatment to boost strength through precipitation hardening. This setup gives our Incoloy 925 bar a melting range around 1343°C and density of 8.05 g/cm³, making it sturdy yet workable. In harsh offshore and chemical environments, where salt water, acids, and high pressures team up, our bar forms a tough barrier against pitting and crevice attacks. We put it through precise solution annealing at 1800-1900°F followed by aging at 1365°F to lock in those peak properties, ensuring every high-strength Incoloy 925 bar we produce hits the mark.

For more details, pls directly contact us.

The industry landscape in 2025 is all about pushing boundaries, and our high-strength Incoloy 925 bar is right in the mix. The global superalloys market is set to jump from $7.82 billion this year to $17.75 billion by 2032, growing at a whopping 12.4% CAGR, fueled by demand in energy and chemical sectors. For nickel superalloys specifically, we're looking at $9.51 billion in 2025, up from $8.79 billion last year. Trends are leaning hard into offshore exploration, with deepwater projects ramping up amid stable oil prices and a push for sustainable extraction. In chemical processing, the shift to green hydrogen and advanced refineries means more need for materials that stand up to corrosive media without frequent swaps. Our Incoloy 925 bar fits this bill, offering cost savings through longer life cycles. With the nickel alloys market eyeing $25.99 billion by 2034 at 5.11% CAGR, Asia-Pacific and Middle East regions are hot spots for growth, where harsh environments demand reliable high-strength options. We're seeing innovations in alloy processing, like better heat treatments for enhanced durability, and our focus on eco-friendly sourcing keeps us ahead.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Applications are where our high-strength Incoloy 925 bar really proves its mettle. In offshore setups, it's perfect for downhole components like tubing, packers, and landing nipples that deal with sour gases full of H2S and CO2. The superior resistance to sulfide stress cracking means no failures under high loads, keeping rigs operational. For surface gear, think safety valves, hangers, and tool joints—our bar handles the combo of mechanical stress and corrosive seawater without batting an eye. In chemical environments, it's a star in piping systems and pump shafts exposed to sulfuric, phosphoric, or acetic acids, with corrosion rates as low as <0.1 mpy in boiling conditions. Marine applications love it for shafting and fasteners, where it resists crevice corrosion in salty waters. Even in petrochemical plants, our Incoloy 925 bar supports high-pressure systems, extending service intervals. It's machinable with carbide tools, weldable without preheating, and formable hot between 1600-2150°F, making it easy to integrate.

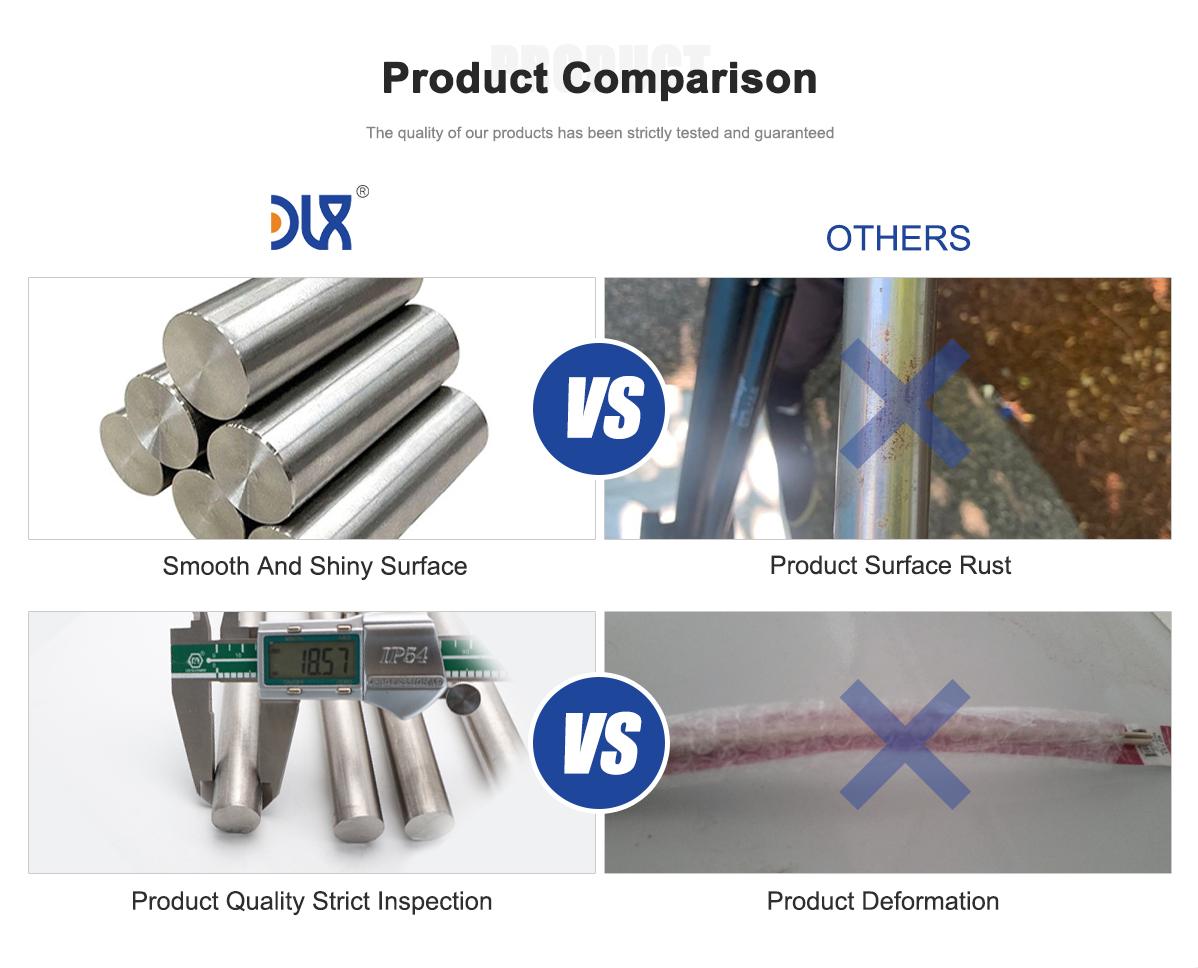

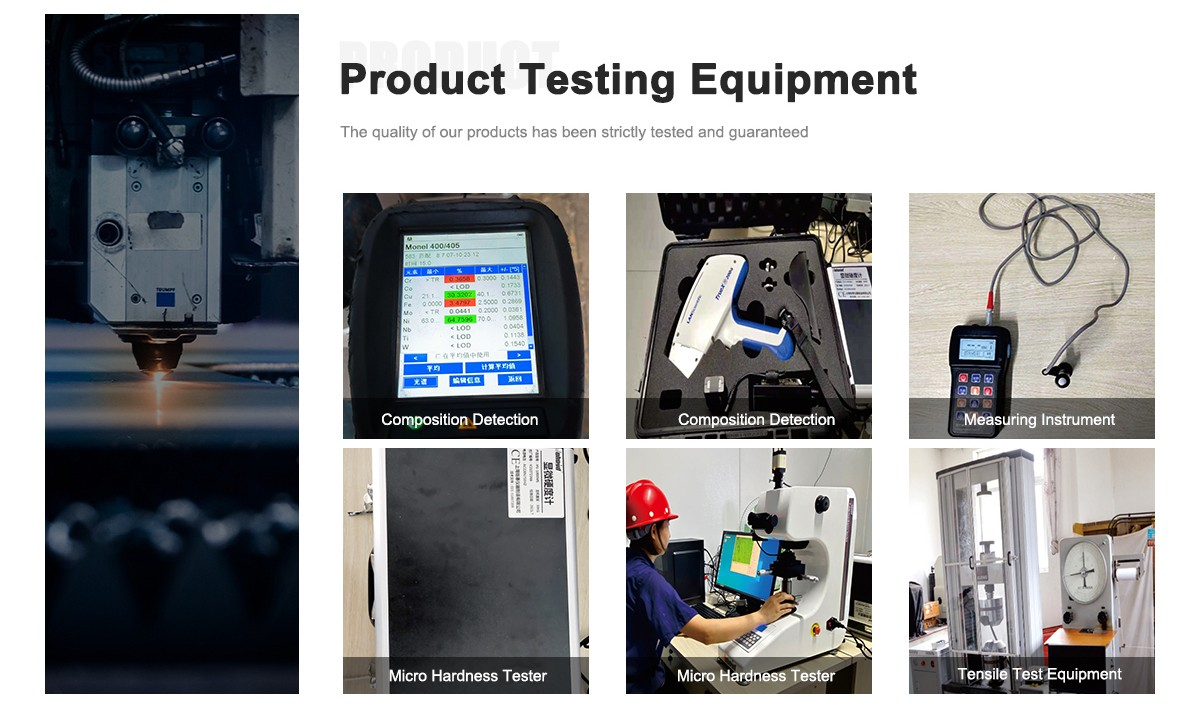

When you compare us to what's typically out there, our advantages pop. While some suppliers churn out standard stuff, we fine-tune our high-strength Incoloy 925 bar with advanced aging processes that push yield strengths to 140 ksi consistently, outperforming basics in fatigue life. We customize diameters from 5mm to 500mm and lengths up to 6m, with finishes that cut down on your machining time. Our raw materials are ultra-pure, minimizing impurities for better resistance in sour wells—clients report 20% less downtime. Testing is thorough: ultrasonic, corrosion sims, and impact at -75°F to ensure it meets NACE MR0175 without issues. Unlike generic options that vary batch to batch, ours delivers uniform hardness of 26-38 HRC, reducing risks in harsh offshore and chemical spots. We back it with fast turnaround and expert advice, from spec selection to installation tips.

Digging into mechanics, our high-strength Incoloy 925 bar hits tensile of 140-175 ksi and yield of 110-140 ksi aged, with 18-27% elongation for flexibility under stress. Impact toughness at 35 ft-lbs min even at low temps makes it ideal for subsea. Corrosion-wise, it shines in NACE solutions with no cracking at 100% yield, and rates under 1 mpy in chloride tests. This edge comes from our controlled composition, avoiding over-aging pitfalls.

Comparison Parameters Table

| Property | Incoloy 825 | Incoloy 925 | Inconel 718 |

|---|---|---|---|

| UNS Designation | N08825 | N09925 | N07718 |

| Nickel Content (%) | 38-46 | 42-46 | 50-55 |

| Chromium Content (%) | 19.5-23.5 | 19.5-22.5 | 17-21 |

| Molybdenum Content (%) | 2.5-3.5 | 2.5-3.5 | 2.8-3.3 |

| Copper Content (%) | 1.5-3 | 1.5-3 | - |

| Titanium Content (%) | 0.6-1.2 | 1.9-2.4 | 0.65-1.15 |

| Aluminum Content (%) | 0.2 max | 0.1-0.5 | 0.2-0.8 |

| Niobium Content (%) | - | 0.5 max | 4.75-5.5 |

| Tensile Strength (ksi) | 85-100 (annealed) | 140-175 (aged) | 180-200 (aged) |

| Yield Strength (ksi) | 35-55 (annealed) | 110-140 (aged) | 150-170 (aged) |

| Elongation (%) | 30-45 | 18-27 | 12-20 |

| Max Service Temp (°F) | Up to 1000 | Up to 1200 | Up to 1300 |

| Corrosion Resistance | Excellent in acids, chlorides | Superior in sour gas, SSC | Outstanding in high-temp oxidation |

| Typical Applications | Chemical processing, pollution control | Offshore downhole, fasteners | Aerospace engines, gas turbines |

Industry analysis highlights opportunities amid challenges like supply volatility. With superalloys at $7.85 billion in 2025 heading to $14.75 billion by 2033, focus is on materials for extreme depths—our Incoloy 925 bar excels here. Trends toward recycling nickel cut costs, something we incorporate for sustainable high-strength solutions. North America's shale and Europe's green chem drive demand.

In specific apps, like subsea manifolds, our bar prevents leaks in crevice-prone areas. For chemical reactors, it endures acid mixes, boosting efficiency. Offshore platforms use it for risers, handling waves and corrosion.

Our strength? Deep inventory for quick ships, superior surface quality to ease fab, and consistent props avoiding hardness inconsistencies. Customers rave about reliability in cyclic loads.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is the chemical composition of Incoloy 925 bar?

Incoloy 925 bar has 42.0-46.0% nickel, 19.5-22.5% chromium, a minimum of 22% iron, 2.5-3.5% molybdenum, 1.5-3.0% copper, 1.9-2.4% titanium, 0.1-0.5% aluminum, up to 1.0% manganese, 0.5% silicon, 0.5% niobium, 0.03% carbon, and 0.03% sulfur.

2. What are the key mechanical properties of Incoloy 925 bar?

Incoloy 925 bar, in the solution-annealed and aged condition, provides tensile strength of 167-175 ksi, yield strength of 110-140 ksi, elongation of 18-27%, reduction of area of 25% minimum, and hardness of 26-38 HRC, with excellent fatigue and impact strength.

3. How does Incoloy 925 bar resist corrosion?

Incoloy 925 bar offers superior resistance to pitting, crevice corrosion, sulfide stress cracking, and stress-corrosion cracking in sour H2S environments, as well as in reducing acids like sulfuric and phosphoric, oxidizing media, and seawater, due to its balanced nickel, chromium, molybdenum, and copper content.

4. What industries commonly use Incoloy 925 bar?

Incoloy 925 bar is commonly used in oil and gas, offshore exploration, chemical processing, marine engineering, and petrochemical industries where high strength meets aggressive corrosive conditions.

5. What are typical applications for Incoloy 925 bar?

Typical applications include downhole tubing, packers, hangers, safety valves, tool joints, fasteners, pump shafts, marine shafting, and high-strength piping systems in harsh offshore and chemical environments.

6. What industry trends are influencing the use of Incoloy 925 bar in 2025?

In 2025, trends include expanding deepwater and subsea oil exploration, growth in hydrogen and renewable chemical processing, with nickel superalloy markets growing at 8.2% CAGR, driven by demand for sustainable, high-performance materials in extreme environments.

7. How does temperature affect the performance of Incoloy 925 bar?

Incoloy 925 bar retains substantial strength up to 1200°F, with minimal degradation in tensile and yield properties, though extended exposure above 1000°F may require optimized aging to maintain peak corrosion resistance and prevent over-aging.

8. What makes Incoloy 925 bar suitable for long-term industrial use?

Its precipitation-hardenable structure delivers high fatigue resistance, minimal embrittlement, and enduring corrosion protection, ensuring reliability and reduced maintenance in prolonged exposure to harsh offshore and chemical conditions.