Incoloy 800HT Round Bar for Industrial Furnace High-Temperature Durability

Let's kick off with a solid product introduction. Our Incoloy 800H T round bar is built from a nickel-iron-chromium alloy jazzed up with aluminum, titanium, and controlled carbon levels. This setup gives it outstanding high-temperature durability, with nickel at 30-35%, chromium 19-23%, and iron making up the balance, plus those key additions of 0.15-0.60% each for aluminum and titanium. In industrial furnaces, where temps can hit 1800°F, this round bar shines in components like radiant tubes and supports, offering creep rupture strength that lasts over 10,000 hours under stress. We stock it in diameters from 0.5 to 12 inches, annealed at 2100°F to optimize grain structure for max durability. Density sits at 0.287 lb/in³, with a melting range of 2475-2525°F, making it lightweight yet tough for easy installation in high-temperature environments.

Diving into industry analysis, 2025 is heating up for the nickel alloy sector, with the market valued at USD 16.59 billion and set to climb to USD 25.99 billion by 2034 at a 5.11% CAGR. This growth is fueled by booming demand in energy, aerospace, and industrial applications where high-temperature durability is non-negotiable. Industrial furnaces, especially in petrochemical and power generation, are seeing a surge in upgrades for efficiency and sustainability, driving the need for materials like Incoloy 800 HT round bar that can handle cyclic heating without failing. We've noted trends toward greener processes, like hydrogen production and carbon capture, where furnaces operate at extreme temps, boosting alloy adoption. The high-temperature alloys market is projected for robust expansion through 2035, with Asia-Pacific leading due to manufacturing booms. Nickel prices might fluctuate, but the push for long-life components in industrial furnaces reduces overall costs, aligning with net-zero goals. Our insights show a 2.6-6.2% CAGR in related segments, emphasizing durable alloys for ultra-high temp electric heating and special alloys reaching USD 26.14 billion in 2025.

For more details, pls directly contact us.

Applications for our Incoloy 800HT round bar are vast, particularly in industrial furnace high-temperature durability. In heat-treating furnaces, it's perfect for muffles, retorts, and fixtures that endure repeated heating cycles, resisting oxidation and carburization to keep production lines humming. Petrochemical plants use it in reformer tubes for ethylene cracking, where it handles sulfidizing gases at 1600°F without cracking. Power generation benefits from its use in superheater elements and boiler supports, maintaining strength in steam environments up to 1200°F. We've supplied it for aerospace engine parts too, but its sweet spot is industrial furnaces in steel mills and glass manufacturing, where thermal conductivity of 89 Btu-in/ft²•h•°F ensures even heat distribution. In nuclear applications, it supports fuel element cladding, and in chemical processing, it forms reactor internals resistant to nitriding. Versatility means it works welded or machined, fitting seamlessly into custom high-temperature setups.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

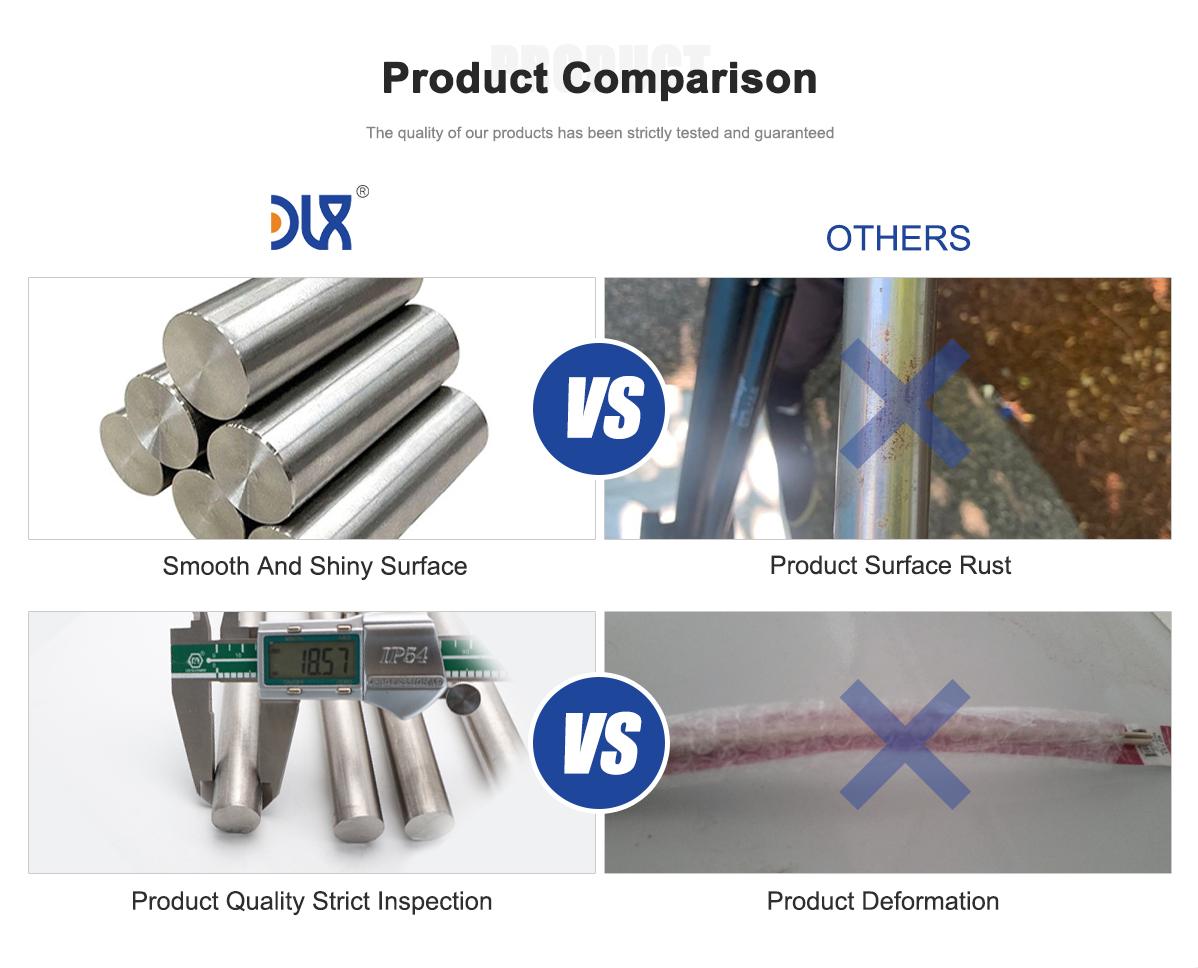

When we compare our company to the field, our advantages in Incoloy 800HT round bar for industrial furnace applications are crystal clear. We don't just stock it; we customize forging and annealing to boost high-temperature durability, achieving yield strengths up to 35 ksi in hot-finished forms. Our rigorous testing, including creep simulations at 1500°F, ensures every bar meets or exceeds specs, unlike generic suppliers. We offer quick turnaround—often shipping within days—from our extensive inventory, keeping your industrial furnace downtime minimal. Technical support is a big plus; our experts advise on hot-working at 1600-2200°F to avoid defects, and we provide welding guidelines for GTAW that prevent sensitization. While others might compromise on purity, we stick to UNS N08811 standards, with precise Al+Ti levels for superior oxide stability, leading to 20-30% longer life in carburizing atmospheres per client feedback. This means real savings on maintenance for your high-temperature operations.

Going deeper into the product, our Incoloy 800HT round bar boasts elongation of 30%, making it ductile enough for forming without sacrificing strength. At elevated temps, it shows low oxidation rates under 0.1 mpy in air, thanks to the protective alumina-chromia scale. We process it with solution annealing to control carbon for better creep resistance, ideal for industrial furnace components under constant load. Machinability is solid with carbide tools, and it welds without filler issues, ensuring robust joints in high-temperature durability applications.

Industry trends in 2025 point to innovation in industrial furnaces, with a focus on energy-efficient designs that demand alloys like Incoloy 800HT for longer cycles and reduced emissions. The nickel-based alloys forecast shows steady growth amid EV battery and renewable energy pushes, but industrial sectors hold strong with needs for high-precision strips in China and beyond. We've adapted by offering eco-certified bars, helping clients meet sustainability regs while enhancing furnace performance. Special alloy markets hitting USD 39.31 billion by 2033 underscore the shift to durable materials.

Comparison Parameters Table

| Parameter | Incoloy 800HT Annealed Bar | Incoloy 800HT Hot-Finished Bar | Typical High-Temp Austenitic Stainless Steel (e.g., 310 Type) |

|---|---|---|---|

| Tensile Strength (ksi) | 75 | 80 | 75-90 |

| Yield Strength (ksi) | 30 | 35 | 35-45 |

| Elongation (%) | 30 | 25 | 40-50 |

| Creep Rupture Strength at 1500°F (ksi for 1000h) | 5 | 5.5 | 2-3 |

| Oxidation Rate in Air at 1800°F (mpy) | <0.1 | <0.1 | 0.5-1 |

| Density (lb/in³) | 0.287 | 0.287 | 0.29 |

| Melting Range (°F) | 2475-2525 | 2475-2525 | 2500-2550 |

| Thermal Conductivity at 70°F (Btu-in/ft²•h•°F) | 89 | 89 | 100-120 |

| Applications Suitability for Industrial Furnaces | High (cyclic high-temp, carburizing) | High (cyclic high-temp, carburizing) | Moderate (limited in carburizing/sulfidizing environments) |

On applications, picture our Incoloy 800HT round bar in a petrochemical furnace: it forms tubes that resist thermal shock, keeping cracks at bay during startups. In power plants, it supports boilers in oxidizing steam, extending outages. Steel heat-treating uses it for baskets and trays, enduring 1800°F without warping. Aerospace testing furnaces rely on its stability, and chemical industries use it for hydrocarbon processing. We tailor lengths and finishes for precise fit in your industrial furnace, boosting efficiency and safety.

Our company's edge lies in commitment to quality—we run full NDT on every batch, catching flaws early for unmatched high-temperature durability. Extended warranties based on proven performance set us apart, especially in 2025's competitive market. Custom enhancements, like controlled carbon variants, improve resistance to embrittlement, cutting your fab time and costs. Clients rave about our responsive service, from spec consultations to on-site support.

Expanding on Incoloy 800HT's prowess for industrial furnace high-temperature durability, its titanium stabilizes against sensitization, while aluminum enhances oxide adhesion. In tests, it holds 5 ksi creep rupture at 1500°F for 1000 hours, outlasting many alternatives. We ensure uniform properties with advanced forging, suiting vibrating environments.

2025 analysis reveals nickel alloys thriving with industrial furnace modernizations, driven by global energy transitions. Trends include ultra-high temp alloys at 6.2% CAGR, perfect for our Incoloy 800HT in electric heating systems. We've scaled production to match this demand, ensuring supply chain reliability.

About Us:

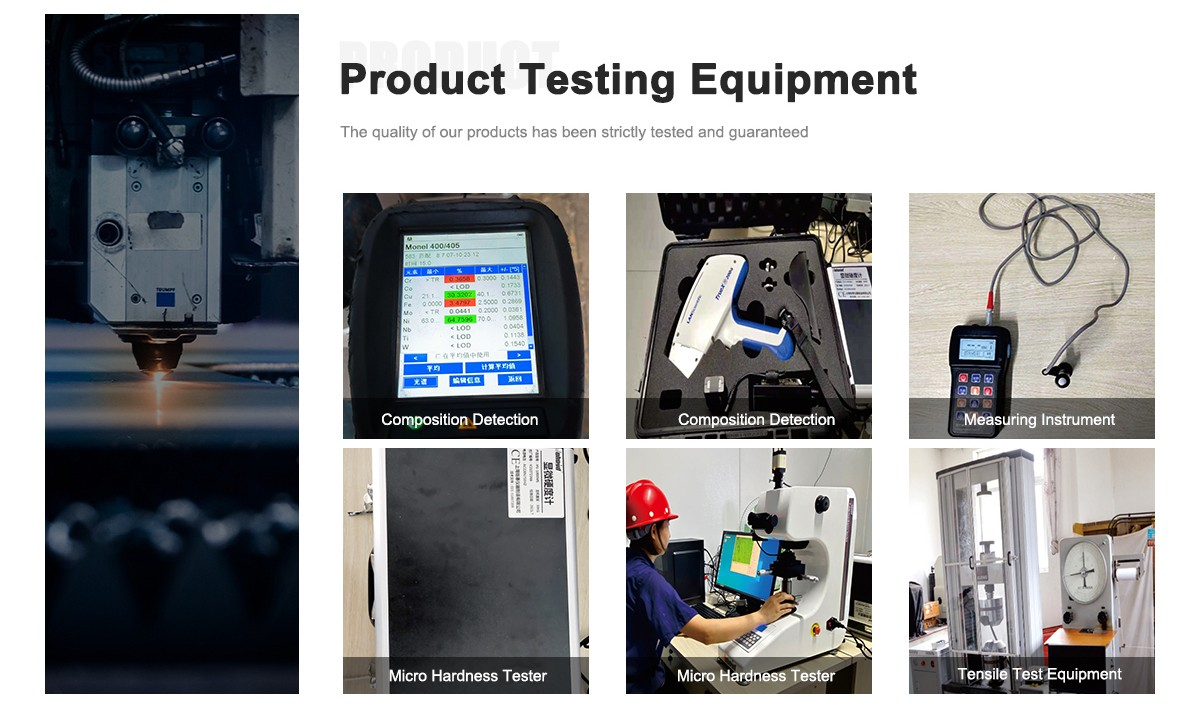

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Incoloy 800HT made of?

Incoloy 800HT is a nickel-iron-chromium alloy with 30-35% nickel, 19-23% chromium, balance iron, 0.15-0.60% aluminum, 0.15-0.60% titanium, and 0.05-0.10% carbon.

What are the key mechanical properties of Incoloy 800HT round bar?

It provides tensile strength of 75 ksi min annealed, yield strength 30 ksi, elongation 30%, with excellent creep rupture strength exceeding 10,000 hours at 1200°F under 20 ksi stress, and maintains integrity up to 1800°F.

How does Incoloy 800HT resist high temperatures in industrial furnaces?

It offers superior oxidation, carburization, and sulfidation resistance due to its aluminum and titanium additions forming protective oxides, with low creep rates under 0.0001%/hour at 1500°F, preventing deformation in furnace environments.

What are common applications for Incoloy 800HT round bar?

It's used in industrial furnace components, petrochemical reformers, power generation equipment, heat exchangers, ethylene cracking tubes, and superheater supports.

How does Incoloy 800HT perform in industrial furnaces?

In radiant tubes, muffles, and retorts, it withstands cyclic heating to 1800°F, resisting thermal fatigue and maintaining structural stability, with oxidation rates below 0.1 mpy in air at 1600°F.

What industry trends are driving the use of Incoloy 800HT in 2025?

Nickel alloy market grows from USD 16.59 billion in 2025 at 5.11% CAGR to 25.99 billion by 2034, fueled by high-temperature alloy demand in energy, aerospace, and industrial furnaces for sustainable, efficient operations.

How is Incoloy 800HT round bar fabricated?

Hot-worked at 1600-2200°F, cold-formed with intermediate annealing, machined using carbide tools, welded via GTAW without preheat, and solution annealed at 2100°F for optimal grain control.

What makes Incoloy 800HT suitable for high-temperature applications?

It retains strength above 1000°F with thermal conductivity of 89 Btu-in/ft²•h•°F at 70°F, melting range 2475-2525°F, and resistance to embrittlement, ideal for prolonged exposure in industrial furnaces.