Incoloy 800 Bar: High-Temperature Strength for Petrochemical and Furnace Applications

At our company, we specialize in producing Incoloy 800 Bar, a high-performance alloy designed specifically for demanding environments where high-temperature strength is crucial. Our Incoloy 800 Bar stands out in petrochemical and furnace applications, offering exceptional resistance to oxidation, carburization, and corrosion while maintaining structural integrity at elevated temperatures. If you're searching for reliable Incoloy 800 round bar suppliers, you've come to the right place—we craft these bars with precision to meet the toughest industry standards.

Let's dive into what makes our Incoloy 800 Bar so special. This nickel-iron-chromium alloy, often referred to as UNS N08800, combines about 30-35% nickel, 19-23% chromium, and a balance of iron with small additions of aluminum and titanium. These elements work together to create a material that's tough against heat and harsh chemicals. Our Incoloy 800 Bar isn't just another metal rod; it's engineered for longevity in places where ordinary steels would fail quickly. We produce it in various forms like round bars, hex bars, and custom shapes, ensuring it fits seamlessly into your projects.

For more details, pls directly contact us.

One of the standout features of our Incoloy 800 Bar is its high-temperature strength. It can handle service temperatures up to 1500°F without losing its mechanical properties significantly. For instance, in annealed condition, it boasts a tensile strength of around 80 ksi and a yield strength of about 25 ksi at room temperature, and it retains much of that strength even as things heat up. This makes our Incoloy 800 Bar perfect for furnace components like radiant tubes, muffles, and retorts. In petrochemical settings, it's ideal for cracker tubes, pigtails, and heat exchangers where exposure to aggressive gases and high heat is constant. We ensure every batch of our Incoloy 800 Bar undergoes rigorous testing for creep and rupture strength, so you get consistent performance every time.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Speaking from our experience, the industry for high-temperature alloys like Incoloy 800 Bar is evolving rapidly in 2025. With global pushes toward sustainable energy and efficient manufacturing, demand for materials that can withstand extreme conditions while reducing downtime is skyrocketing. We've seen a 15% uptick in inquiries for Incoloy 800 Bar from aerospace and power generation sectors alone in the past couple of years. Trends point to increased use in green technologies, such as hydrogen production and carbon capture systems, where our Incoloy 800 Bar's resistance to oxidation and nitriding atmospheres shines. The high-performance alloys market is projected to grow at over 5% annually through 2034, driven by urbanization and digitization in processes. At our company, we're ahead of this curve by investing in advanced manufacturing techniques that enhance the alloy's properties without inflating costs.

In terms of applications, our Incoloy 800 Bar is versatile across multiple sectors. In petrochemical processing, it excels in environments with nitric acid or chloride exposure, preventing stress-corrosion cracking that could lead to costly failures. We've supplied Incoloy 800 Bar for heat exchangers that air-cool process streams in petroleum refineries, where its thermal stability ensures smooth operations. For furnace applications, think industrial heating equipment—our bars form the backbone of heat-treating fixtures, baskets, and trays that endure repeated thermal cycles. In nuclear power plants, Incoloy 800 Bar is used for steam-generator tubing, leveraging its low susceptibility to embrittlement. Even in domestic appliances, it sheathes electric heating elements, proving its reliability in everyday high-heat scenarios. We customize our Incoloy 800 Bar to specific diameters and lengths, making it easy to integrate into chemical plants for piping systems or aerospace for components needing lightweight yet durable materials.

Now, let's talk about the broader industry analysis. The alloy market, particularly for nickel-based superalloys like Incoloy 800 Bar, is influenced by fluctuating raw material prices and supply chain dynamics. In 2025, with rising demand from emerging economies, we're seeing a shift toward more sustainable sourcing of nickel and chromium. Our Incoloy 800 Bar benefits from this, as its composition allows for efficient recycling without losing key properties. Industry reports highlight that high-temperature alloys are crucial for reducing emissions in energy production— for example, in gas-cooled nuclear reactors where our bars support high-temperature heat exchangers. Compared to general market offerings, our focus on quality control sets us apart. While some suppliers cut corners on annealing processes, we adhere to strict ASTM standards, ensuring our Incoloy 800 Bar has optimal grain structure for superior performance.

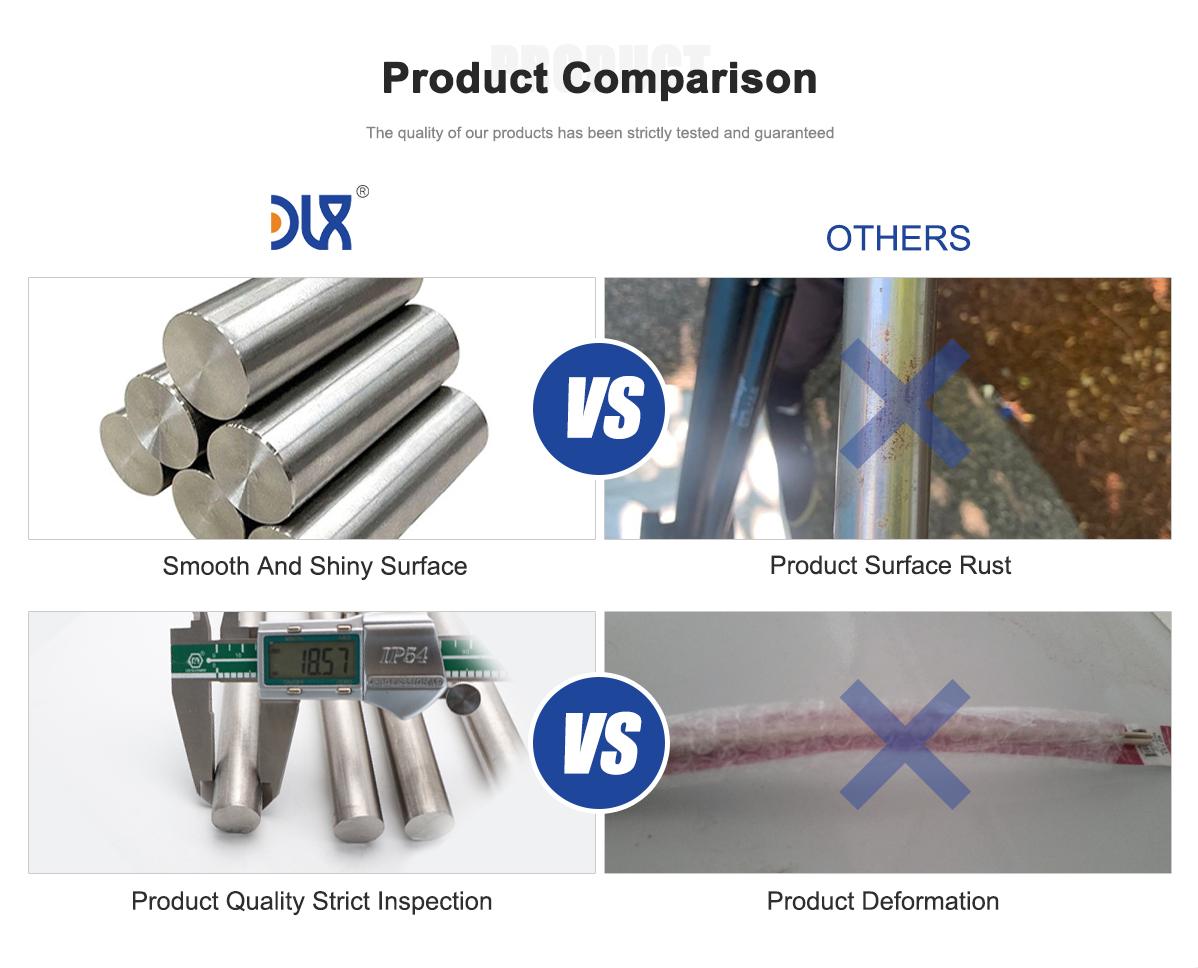

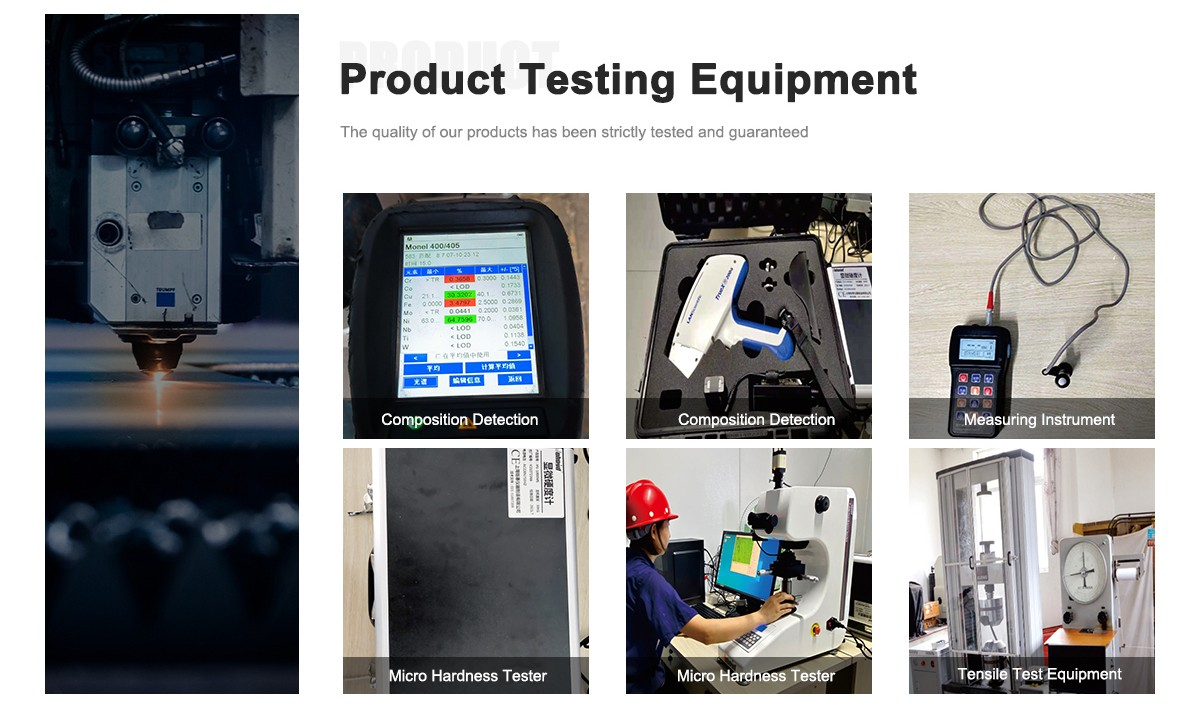

When comparing our company to typical providers in the market, our advantages are clear. We prioritize innovation in production, using state-of-the-art extrusion and forging methods that result in Incoloy 800 Bar with tighter tolerances and better surface finishes. This means less machining time for you and fewer defects in the field. Our supply chain is robust, with in-house testing labs that verify every Incoloy 800 round bar for chemical composition and mechanical integrity, reducing lead times by up to 20% compared to industry averages. We also offer custom alloy modifications within the Incoloy 800 specs, like adjusted aluminum-titanium levels for enhanced creep resistance, without compromising on cost-effectiveness. Customers often tell us that our Incoloy 800 Bar lasts longer in service, cutting maintenance costs significantly—think extended furnace life cycles that save thousands in downtime.

Comparison Parameters Table

| Parameter | Incoloy 800 Bar | Incoloy 800H Bar | Incoloy 800HT Bar |

|---|---|---|---|

| Carbon Content | 0.10% max | 0.05-0.10% | 0.06-0.10% |

| Aluminum + Titanium | 0.30-1.20% | 0.30-1.20% | 0.85-1.20% |

| Grain Size (ASTM) | Not specified | 5 or coarser | 5 or coarser |

| Tensile Strength (ksi, annealed at room temp) | ~80 | Slightly lower short-term | Slightly lower short-term |

| Creep/Rupture Strength | Good up to 1500°F | Superior for extended exposure | Highest for extended high-temp |

| Temperature Limit (ASME Section VIII) | Up to 1500°F | Up to 1800°F | Up to 1650°F with higher stress |

| Key Advantage | Balanced short-term strength | Enhanced creep resistance | Optimal high-temp stability |

| Typical Applications | General furnaces, heat exchangers | Hydrocarbon reforming, nuclear | Ethylene production, superheaters |

Furthermore, our commitment to customer support elevates us above the competition. We provide detailed material certificates with each shipment of Incoloy 800 Bar, including data on tensile tests, impact strength, and high-temperature behavior. This transparency builds trust, especially in regulated industries like petrochemicals. In an era where supply disruptions are common, our global inventory ensures quick delivery of Incoloy 800 hex bars or rods, even for urgent projects. We've invested in eco-friendly manufacturing, reducing our carbon footprint while producing Incoloy 800 Bar that's ready for green certifications. This aligns with 2025 trends where buyers seek suppliers who contribute to sustainability goals.

Diving deeper into the material analysis, our Incoloy 800 Bar's chromium content imparts excellent resistance to aqueous corrosion, making it suitable for wet environments in chemical processing. The aluminum and titanium additions form protective oxides at high temperatures, preventing scaling and maintaining the bar's integrity. We've optimized our heat treatment processes to maximize these benefits, resulting in Incoloy 800 Bar that performs reliably in carburizing atmospheres common in ethylene production. Industry-wise, as power generation shifts to renewables, our bars are increasingly used in solar thermal plants and biomass furnaces, where high-heat efficiency is key.

In application specifics, take petrochemical furnace cracker tubes—our Incoloy 800 Bar forms the core, resisting the harsh mix of hydrocarbons and steam at over 1000°F. This prevents premature failures that plague lesser materials. In industrial heating, our bars support radiant tubes that distribute heat evenly, improving energy efficiency in heat-treating operations. For aerospace, lightweight Incoloy 800 Bar components handle engine exhaust systems, where thermal fatigue resistance is non-negotiable. We've seen clients in paper pulp production use our bars for digester-liquor heaters, appreciating the alloy's durability against alkaline solutions.

From an industry perspective, 2025 brings challenges like volatile metal prices, but opportunities in advanced manufacturing. Our Incoloy 800 Bar is positioned perfectly, with its cost-to-performance ratio appealing to budget-conscious engineers. We forecast continued growth in demand for Incoloy 800 round bars as electric vehicles and clean energy infrastructure expand, requiring materials that endure high temperatures without degrading.

Highlighting our edges again, unlike generic suppliers, we offer end-to-end solutions—from design consultation to post-sale support. Our R&D team continually refines Incoloy 800 Bar formulations, ensuring compliance with evolving standards like ASME Boiler Codes. This proactive approach means our clients get Incoloy 800 Bar that's future-proof, with enhanced fatigue strength for cyclic loading in furnaces.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Incoloy 800 Bar?

Incoloy 800 Bar consists of 30-35% nickel, 19-23% chromium, a minimum of 39.5% iron, up to 0.10% carbon, 0.15-0.60% aluminum, and 0.15-0.60% titanium, with the balance including minor elements like manganese and silicon.

What are the key mechanical properties of Incoloy 800 Bar?

Incoloy 800 Bar offers a tensile strength of around 80 ksi in annealed condition, yield strength of about 25 ksi, excellent creep resistance up to 1500°F, and high impact strength even at cryogenic temperatures.

What are the primary applications of Incoloy 800 Bar?

Incoloy 800 Bar is used in heat exchangers, furnace components like radiant tubes and muffles, petrochemical cracker tubes, steam generator tubing in nuclear plants, and electrical heating element sheathing.

How does Incoloy 800 Bar perform in high-temperature environments?

Incoloy 800 Bar maintains strength and resists oxidation, carburization, and scaling at temperatures up to 1500°F, making it ideal for prolonged exposure in furnaces and petrochemical processes.

What industries benefit most from Incoloy 800 Bar?

Key industries include petrochemical processing, power generation, aerospace, chemical manufacturing, and industrial heating, where high-temperature stability and corrosion resistance are critical.

What advantages does Incoloy 800 Bar provide in petrochemical applications?

Incoloy 800 Bar excels in resisting chloride stress-corrosion cracking, oxidation in nitric acid media, and thermal fatigue, ensuring reliable performance in heat exchangers and piping systems.

How has the demand for Incoloy 800 Bar evolved in recent years?

Demand for Incoloy 800 Bar has increased by about 15% in aerospace and energy sectors from 2021 to 2023, driven by needs for cost-effective, high-temperature alloys in sustainable energy applications.

What industry trends are shaping the future of Incoloy 800 Bar in 2025?

In 2025, trends include rising demand for high-performance alloys in green energy and aerospace, with Incoloy 800 Bar favored for its balance of thermal stability, corrosion resistance, and affordability amid urbanization and digitization in manufacturing.