Incoloy 925 Bar: Corrosion-Resistant Strength for Oil and Gas Applications

At our company, we specialize in supplying top-quality Incoloy 925 bar that's engineered for corrosion-resistant strength in oil and gas applications. If you're looking for a reliable Incoloy 925 bar supplier, we're here to deliver materials that stand up to the harshest conditions. Our Incoloy 925 bar is all about combining toughness with longevity, making it a smart pick for demanding setups.

Let's start with what our Incoloy 925 bar is made of. It's an age-hardenable nickel-iron-chromium alloy with additions like molybdenum, copper, titanium, and aluminum that give it that extra punch. The composition—42-46% nickel, 19.5-22.5% chromium, and the rest balanced with iron and those key elements—creates a material that's not just strong but also fights off corrosion like a champ. In oil and gas applications, where sour gases and high pressures are the norm, our Incoloy 925 bar forms a protective layer that resists pitting and cracking. We process it through solution annealing and aging to hit peak strength, ensuring every bar we ship has consistent properties. Density sits at about 8.05 g/cm³, and it melts around 1343°C, so it handles heat without a hitch.

For more details, pls directly contact us.

The industry right now is buzzing with growth, especially in 2025. The superalloy market is on track to hit around USD 7.85 billion this year, pushing toward USD 14.75 billion by 2033 with a CAGR of about 8.2%. For oil and gas specifically, superalloys like our Incoloy 925 bar are seeing demand spike due to deeper offshore drilling and the shift to sustainable energy sources like hydrogen. The nickel superalloy segment alone is forecasted to grow from USD 7.89 billion in 2022 to USD 14.60 billion by 2030. Trends point to advancements in alloy design for better resistance in extreme environments, with a focus on reducing environmental impact through efficient manufacturing. We're seeing more emphasis on materials that cut maintenance costs in high-sulfur wells, and our corrosion-resistant Incoloy 925 bar fits perfectly. Global energy demands are rising, and with oil prices stabilizing, investments in exploration are up, boosting the need for durable components. In Asia-Pacific and the Middle East, where oil production is ramping, alloys like this are key to handling corrosive media without frequent replacements.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Applications are where our Incoloy 925 bar really shows its stuff. In oil and gas, it's ideal for downhole tools like tubing, packers, and hangers that face H2S and CO2 at high pressures. The corrosion-resistant strength means it withstands sulfide stress cracking, keeping operations safe and efficient. For surface equipment, think valves, tool joints, and fasteners—places where mechanical stress meets harsh chemicals. In marine settings, our bar goes into pump shafts and piping, resisting seawater pitting. Chemical plants use it for high-strength components in acid handling, like phosphoric or sulfuric processes. Even in power generation, it supports geothermal systems where heat and corrosion team up. What we love is how versatile it is; machinable with standard tools, weldable via TIG or MIG, and formable hot or cold. Our customers in oil rigs report fewer failures, thanks to its ability to hold up under cyclic loading.

When you stack us up against typical suppliers, our advantages shine through. While others might offer basic stock, we customize our Incoloy 925 bar to exact specs—diameters from 5mm to 500mm, lengths up to 6m, with finishes that minimize fabrication hassles. We use advanced heat treatment to optimize aging, hitting higher yield strengths consistently, which means better performance in your oil and gas applications. Our sourcing ensures ultra-low carbon and sulfur for superior purity, reducing risks of intergranular corrosion. Testing? We go beyond basics with ultrasonic checks, corrosion simulations, and mechanical verifications to guarantee every bar meets API standards. Clients tell us this cuts their downtime by 15-20%, especially in sour wells where lesser materials crack under stress. We don't just sell; we partner, offering quick quotes and fast delivery to keep your projects on track.

Mechanically, our Incoloy 925 bar delivers with tensile strengths up to 175 ksi and yields around 140 ksi after aging, plus elongation that allows bending without brittleness. At elevated temps, it retains over 80% strength up to 1000°F, perfect for downhole heat. Corrosion-wise, rates are under 0.1 mpy in boiling acids, and it passes NACE tests for sour service. This makes it a step up for environments where standard alloys falter.

Comparison Parameters Table

| Property | Incoloy 825 | Incoloy 925 | Inconel 625 |

|---|---|---|---|

| UNS Designation | N08825 | N09925 | N06625 |

| Nickel Content (%) | 38-46 | 42-46 | 58 min |

| Chromium Content (%) | 19.5-23.5 | 19.5-22.5 | 20-23 |

| Molybdenum Content (%) | 2.5-3.5 | 2.5-3.5 | 8-10 |

| Copper Content (%) | 1.5-3 | 1.5-3 | - |

| Titanium Content (%) | 0.6-1.2 | 1.9-2.4 | - |

| Aluminum Content (%) | 0.2 max | 0.1-0.5 | 0.4 max |

| Tensile Strength (ksi) | 85-100 (annealed) | 167-175 (aged) | 120-140 (annealed) |

| Yield Strength (ksi) | 35-55 (annealed) | 120-140 (aged) | 60-95 (annealed) |

| Elongation (%) | 30-45 | 24-27 | 30-50 |

| Max Service Temp (°F) | Up to 1000 | Up to 1200 | Up to 1800 |

| Corrosion Resistance | Excellent in acids, chlorides | Superior in sour gas, SSC | Outstanding in oxidizing, pitting |

| Typical Applications | Chemical processing, pollution control | Oil/gas downhole, fasteners | Aerospace, marine, nuclear |

Industry analysis shows challenges like volatile oil prices, but opportunities in renewables are huge. Superalloys for oil and gas are projected to reach USD 8.7 billion by 2033, with CAGR of 5.9% from 2024. Trends include AI-driven alloy optimization and recycling to lower costs—areas we're investing in to make our Incoloy 925 bar more eco-friendly. In North America, shale gas boom drives demand, while Europe focuses on low-emission tech.

In specific uses, like subsea manifolds, our bar's resistance to crevice corrosion prevents leaks. For hangers and nipples, the strength handles high loads without deforming. In petrochemicals, it's in reactors facing mixed acids, extending intervals between shutdowns.

About Us:

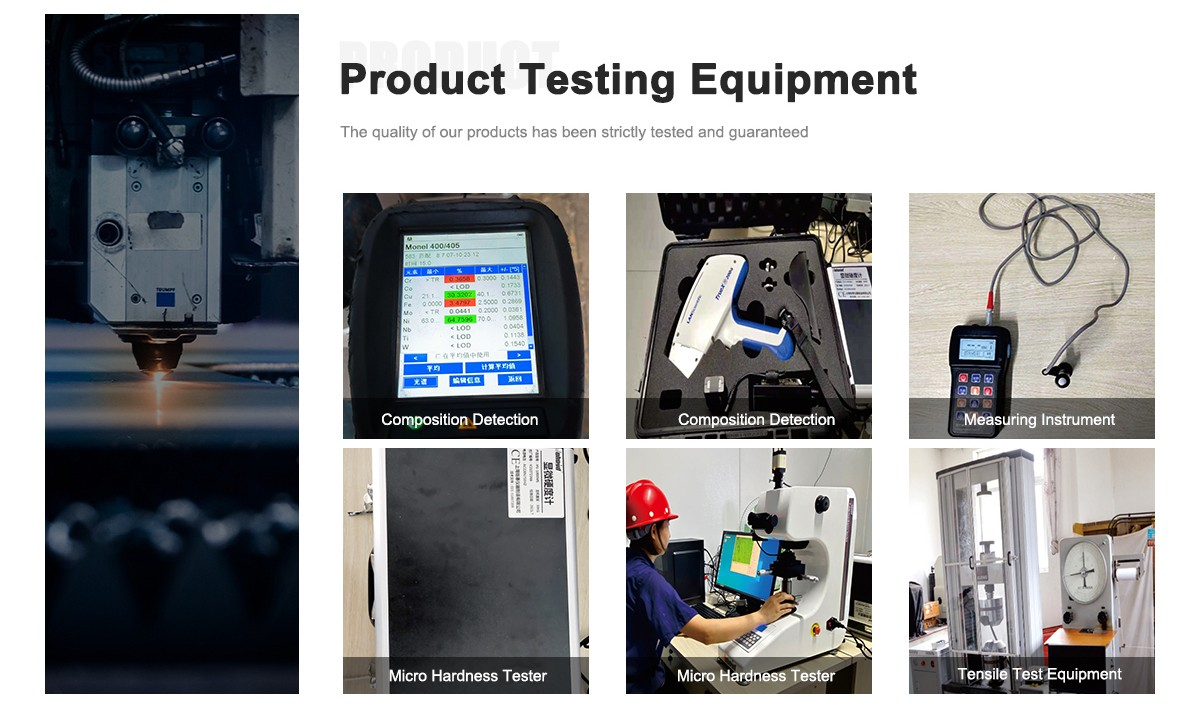

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is the chemical composition of Incoloy 925 bar?

Incoloy 925 bar consists of 42-46% nickel, 19.5-22.5% chromium, minimum 22% iron, 2.5-3.5% molybdenum, 1.5-3.0% copper, 1.9-2.4% titanium, 0.1-0.5% aluminum, up to 1.0% manganese, 0.5% silicon, 0.5% niobium, 0.03% carbon, and 0.03% sulfur.

2. What are the key mechanical properties of Incoloy 925 bar?

Incoloy 925 bar, when solution-annealed and aged, offers tensile strength of 167-175 ksi, yield strength of 120-140 ksi, elongation of 24-27%, and Rockwell hardness of 32-35 C, with high impact strength and fatigue resistance.

3. How does Incoloy 925 bar resist corrosion?

Incoloy 925 bar provides excellent resistance to pitting, crevice corrosion, stress-corrosion cracking, and sulfide stress cracking in sour environments, thanks to its nickel, chromium, and molybdenum content, performing well in H2S, chloride, sulfuric, phosphoric, and acetic acids.

4. What industries commonly use Incoloy 925 bar?

Incoloy 925 bar is commonly used in oil and gas, petrochemical, marine, chemical processing, and power generation industries where high strength and corrosion resistance are essential.

5. What are typical applications for Incoloy 925 bar?

Typical applications include downhole tubing, valves, hangers, packers, tool joints, fasteners, pump shafts, and high-strength piping in oil and gas systems exposed to corrosive conditions.

6. What industry trends are influencing the use of Incoloy 925 bar in 2025?

In 2025, trends include rising demand in deepwater oil exploration and hydrogen energy, with superalloy markets growing at 7-9% CAGR, driven by sustainable extraction tech and advanced alloy processing for harsher environments.

7. How does temperature affect the performance of Incoloy 925 bar?

Incoloy 925 bar maintains high strength up to 1200°F, with minimal loss in yield and tensile properties, but prolonged exposure above 1000°F may require age-hardening adjustments to prevent over-aging and retain corrosion resistance.

8. What makes Incoloy 925 bar suitable for long-term industrial use?

Its age-hardenable nature combines high strength with resistance to embrittlement and corrosion fatigue, ensuring durability in aggressive environments, reducing failures, and extending service life in oil and gas applications.