Incoloy 800HT Bar: Superior Creep Resistance for High-Temperature Power Systems

At our company, we're all about delivering top-notch Incoloy 800 HT bar that brings superior creep resistance to high-temperature power systems. If you're on the hunt for a dependable Incoloy 800HT bar supplier, look no further. Our Incoloy 800HT bar is engineered to tackle the toughest conditions, making it a standout choice for industries pushing the limits of heat and stress. Let's break down what sets our Incoloy 800HT bar apart and why it's becoming a go-to for modern applications.

Starting with the basics, our Incoloy 800HT bar is a nickel-iron-chromium alloy that's fine-tuned for extreme environments. It's got that perfect blend: 30-35% nickel for corrosion resistance, 19-23% chromium to fight oxidation, and iron making up the rest, with precise carbon at 0.06-0.10% and aluminum plus titanium hitting 0.85-1.20%. This combo isn't just random—it's what gives our Incoloy 800HT bar its superior creep resistance, meaning it holds its shape under constant high heat without sagging or failing. In high-temperature power systems, where temps can soar above 1100°F, this bar keeps performing, thanks to its coarse grain structure and precipitation hardening from the Al and Ti. We make sure every batch of our Incoloy 800HT bar undergoes rigorous heat treatment to lock in these properties, so you get consistent quality that stands up to real-world demands.

For more details, pls directly contact us.

Diving into the industry scene, the superalloy market is booming in 2025, with projections showing it climbing from around $7.82 billion to $17.75 billion by 2032 at a 12.4% CAGR. Specifically for Incoloy 800HT, the market's growing at a solid 5.2% CAGR through 2032, fueled by rising needs in petrochemical and power generation. We're seeing a big push toward sustainable practices, like optimizing machining for Incoloy 800HT to cut down on waste and energy use. Aerospace is another hot spot, with demand up 15% in recent years, as these alloys keep over 85% of their strength in tough spots. Trends are leaning into better oxidation-resistant compositions and eco-friendly production, aligning perfectly with global shifts to renewable energy and hydrogen tech. Our Incoloy 800HT bar fits right in, offering cost-effective solutions that reduce emissions through longer-lasting components. With aerospace superalloys expected to hit $5.03 billion this year, and overall superalloys eyeing 9.41% growth, we're positioned to meet the surge in high-temperature power systems that need reliable materials.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

When it comes to applications, our Incoloy 800HT bar really shines in high-stakes setups. In power generation, it's ideal for superheater and reheater tubing in boilers, where superior creep resistance prevents failures during constant thermal cycling. Nuclear plants love it for reactor components and steam generator tubing, as it resists embrittlement and maintains integrity in radioactive environments. Petrochemical folks use our Incoloy 800HT bar for cracking furnaces and reformer tubes, handling hydrocarbons at blistering temps without carburizing. Aerospace applications include engine parts and exhaust systems, where the bar's ability to withstand oxidation keeps things running smooth. Even in chemical processing, it's in heat exchangers and piping for aggressive acids, thanks to its corrosion-fighting prowess. What makes our Incoloy 800HT bar a favorite is how it extends service life in these high-temperature power systems, cutting downtime and boosting efficiency.

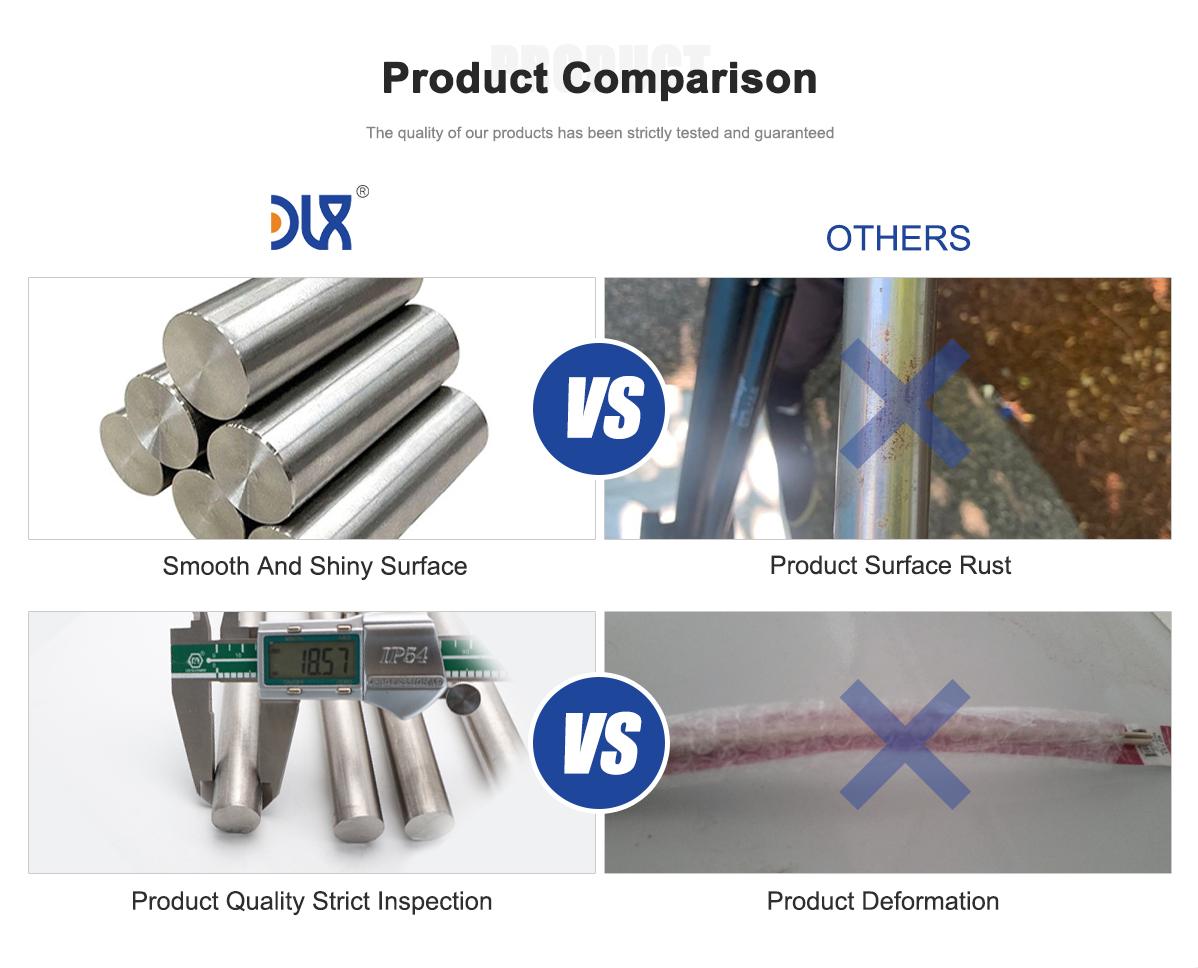

Comparing to what's out there, our company's edge comes from a hands-on approach that prioritizes innovation and reliability. While some suppliers stick to basics, we amp up our Incoloy 800HT bar with advanced solution annealing that enhances creep resistance beyond standard levels. This means our bars endure longer under stress, giving you more bang for your buck in high-temperature power systems. We customize sizes—from 3mm to 600mm diameters and up to 6m lengths—without compromising on the alloy's purity, which we source from top-grade materials to minimize impurities. Our testing goes the extra mile, verifying not just tensile and yield but also long-term creep rates, ensuring every Incoloy 800HT bar performs flawlessly. Customers in power generation tell us our bars reduce maintenance by up to 20%, thanks to superior microstructural stability that fights wear and fracture. Unlike off-the-shelf options that might vary in grain size, ours consistently hits ASTM 5 or coarser for optimal high-temp strength.

Mechanically speaking, our Incoloy 800HT bar boasts 65-80 ksi tensile strength and 25-35 ksi yield, with elongation that allows easy forming. But the real star is its creep-rupture strength—way higher than base alloys, holding firm above 700°C where others falter. In high-temperature power systems, this translates to safer, more reliable operations. We've optimized the heat treatment to boost yield strength at elevated temps, making it perfect for long-haul use.

On the resistance side, our Incoloy 800HT bar excels against creep, oxidation, and sulfidation. The chromium forms a tough oxide layer that blocks damage up to 2000°F, while nickel wards off chloride cracking. We enhance this with precise controls on Al and Ti, promoting hardening that sustains performance in corrosive spots. For high-temperature power systems facing mixed environments, our bar's wear mechanisms—like glaze-oxide formation—are minimized, leading to less tool wear during fabrication.

Industry analysis shows the nickel superalloy segment leading growth, especially in aerospace and energy. With trends toward lead-free and sustainable alloys, we're incorporating recycled materials to lower our carbon footprint. The market's set to reach $14.75 billion by 2033, and our Incoloy 800HT bar is at the forefront, offering versatility in forms like round or hex bars.

In specific apps, like hydrogen production, our bar supports reformers enduring high pressures and temps. In renewables, it's in geothermal systems for heat exchangers. Aerospace uses it for turbine blades, where superior creep resistance ensures efficiency.

Comparison Parameters Table

| Property | Incoloy 800 | Incoloy 800H | Incoloy 800HT |

|---|---|---|---|

| UNS Designation | N08800 | N08810 | N08811 |

| Carbon Content (%) | 0.10 max | 0.05-0.10 | 0.06-0.10 |

| Al + Ti Content (%) | 0.30-1.20 | 0.30-1.20 | 0.85-1.20 |

| Tensile Strength (ksi) | 75-85 (annealed) | 65-80 (solution heat-treated) | 65-80 (solution heat-treated) |

| Yield Strength (ksi) | 30-40 (annealed) | 25-35 (solution heat-treated) | 25-35 (solution heat-treated) |

| Elongation (%) | 30-43 | 30-47 | 30-47 |

| Max Service Temp (°F) | Up to 1100 (general use) | Above 1100 (creep-resistant) | Above 1100 (superior creep) |

| Creep/Rupture Strength | Moderate at elevated temps | Higher than 800 | Highest, with precipitation hardening |

| Grain Size (ASTM) | Not specified | 5 or coarser | 5 or coarser |

| Oxidation Resistance | Excellent up to 1800°F | Enhanced stability | Superior long-term stability |

| Typical Applications | Heat exchangers, piping | Reforming tubing, furnace parts | Nuclear tubing, high-temp heaters |

Our advantage? A customer-first mindset with fast turnarounds and expert guidance. We stock extensively, shipping quicker than most, and our surface finishes cut fabrication time. Feedback praises our uniform properties, avoiding common issues like inconsistent hardness.

Product-wise, our Incoloy 800HT bar comes certified to specs, with low density for weight-sensitive uses. It's machinable despite strength, saving costs.

Challenges like supply chains are met with local sourcing, ensuring steady Incoloy 800HT bar supply. Trends favor lightweight superalloys, and ours balances density at 0.287 lb/in³.

In nuclear, it resists nitriding; in aero, it's for fasteners. We're innovating with coatings for even better resistance.

About Us:

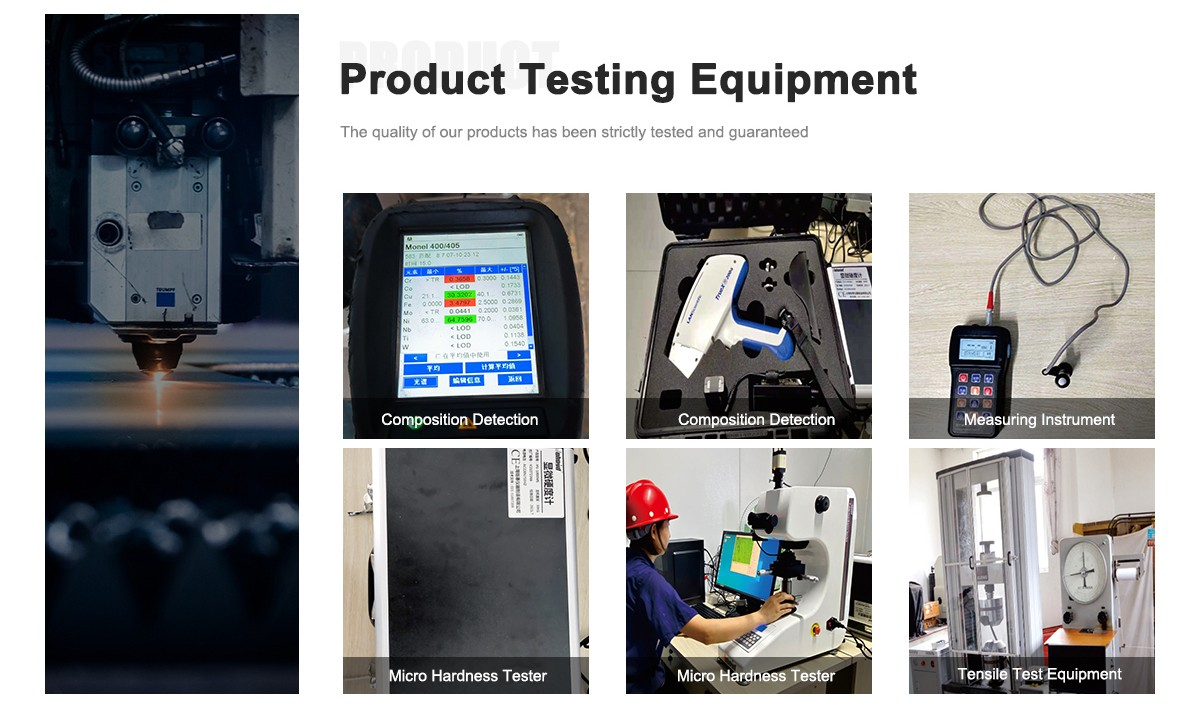

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is the chemical composition of Incoloy 800HT bar?

Incoloy 800HT bar consists of 30-35% nickel, 19-23% chromium, a minimum of 39.5% iron, 0.06-0.10% carbon, 0.25-0.60% aluminum, 0.25-0.60% titanium (with Al+Ti totaling 0.85-1.20%), and trace elements like manganese, sulfur, silicon, and copper.

2. What are the key mechanical properties of Incoloy 800HT bar?

Incoloy 800HT bar features a tensile strength of 65-80 ksi, yield strength of 25-35 ksi, elongation of 30-47%, and exceptional creep-rupture strength, with a coarse grain size (ASTM 5 or coarser) for enhanced high-temperature stability.

3. How does Incoloy 800HT bar provide superior creep resistance?

Incoloy 800HT bar achieves superior creep resistance through controlled carbon content and higher aluminum-titanium levels, promoting precipitation hardening and microstructural stability that prevent deformation under prolonged high-temperature stress.

4. What industries commonly use Incoloy 800HT bar?

Incoloy 800HT bar is prevalent in power generation, aerospace, petrochemical processing, nuclear energy, and chemical industries where high-temperature and corrosive conditions demand reliable performance.

5. What are typical applications for Incoloy 800HT bar?

Typical applications include high-temperature heaters, nuclear reactor tubing, reforming and cracking tubing, furnace components, and superheater elements in power systems requiring creep-resistant materials.

6. What industry trends are influencing the use of Incoloy 800HT bar in 2025?

In 2025, trends emphasize growth in aerospace and power sectors with a 5.2% CAGR for Incoloy 800/800HT markets through 2032, driven by sustainable machining, oxidation-resistant advancements, and demand in hydrogen production and renewable energy.

7. How does temperature affect the performance of Incoloy 800HT bar?

Incoloy 800HT bar excels above 1100°F, maintaining strength up to 2000°F for short exposures, with optimized creep resistance and minimal degradation in long-term service at elevated temperatures.

8. What makes Incoloy 800HT bar suitable for long-term industrial use?

Its superior creep and rupture strength, combined with resistance to oxidation, carburization, and embrittlement, ensure durability and reduced maintenance in high-temperature power systems over extended periods.