Incoloy A-286 Bar for Turbine Component High-Stress Resilience

At our company, we've specialized in Incoloy A-286 bar for turbine component high-stress resilience, and we've seen how this superalloy tackles the toughest challenges in high-heat, high-pressure environments. If you're engineering turbine parts that need to hold up under extreme stress without giving in, our Incoloy A-286 bar is the solid pick that delivers consistent performance.

Let's start with the product introduction. Our Incoloy A-286 bar is an iron-based superalloy packed with nickel at 24-27%, chromium 13.5-16%, titanium 1.9-2.35%, molybdenum 1-1.5%, and other elements like vanadium and boron for that extra punch. This composition makes it age-hardenable, boosting tensile strength to 145 ksi and yield to 100 ksi after proper heat treatment. In turbine components, where high-stress resilience is key, it shines with creep-rupture properties that keep parts intact over thousands of hours at 1200°F. We offer it in round bars from 0.5 to 10 inches in diameter, solution treated at 1800°F or fully aged, with a density of 0.286 lb/in³ and melting range of 2500-2600°F. This bar isn't just metal—it's engineered for oxidation resistance under 0.1 mpy at 1300°F, making it perfect for turbine discs and shafts that face constant thermal cycling.

For more details, pls directly contact us.

Shifting to industry analysis, 2025 is a banner year for the superalloy market, valued at $7.82 billion and projected to hit $17.75 billion by 2032 with a 12.4% CAGR. This surge comes from booming aerospace and energy sectors, where turbine components demand materials with top-notch high-stress resilience. We've noticed trends leaning toward sustainable aviation fuels and hydrogen turbines, pushing for alloys like Incoloy A-286 that handle higher temps and stresses while reducing emissions. The aerospace superalloys segment alone is growing from $5.6 billion in 2023 to $9.8 billion by 2032, driven by next-gen engines in Asia-Pacific. Nickel-based alloys are at the forefront, with market growth fueled by EV battery tech spillover into turbine innovations. In 2025, volatility in nickel prices hasn't slowed demand; instead, it's highlighted cost-effective iron-based options like our Incoloy A-286 bar for turbine efficiency. Overall, the high-performance alloys market is set to reach $17.58 billion by 2033, emphasizing resilience in high-stress applications amid global energy transitions.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Applications for our Incoloy A-286 bar are diverse, especially in turbine component high-stress resilience. In jet engines, it's ideal for fasteners, discs, and blades that endure 1300°F and vibrational stresses without cracking. Aerospace manufacturers use it in afterburner parts and supercharger wheels, where its notched ductility prevents failures under load. Beyond aviation, oil and gas sectors apply it in manifolds and downhole tools facing corrosive, high-pressure conditions. We've supplied it for automotive exhaust valves and cryogenic equipment, but its core strength lies in power generation turbines, supporting shafts and casings in steam and gas setups. Springs and non-magnetic components in medical devices benefit from its corrosion resistance too. In high-stress resilience scenarios, like turbine rotors spinning at high RPMs, it resists fatigue with elongation up to 15% in aged form. We customize bars for seamless integration, ensuring thermal conductivity of 80 Btu-in/ft²•h•°F for efficient heat management.

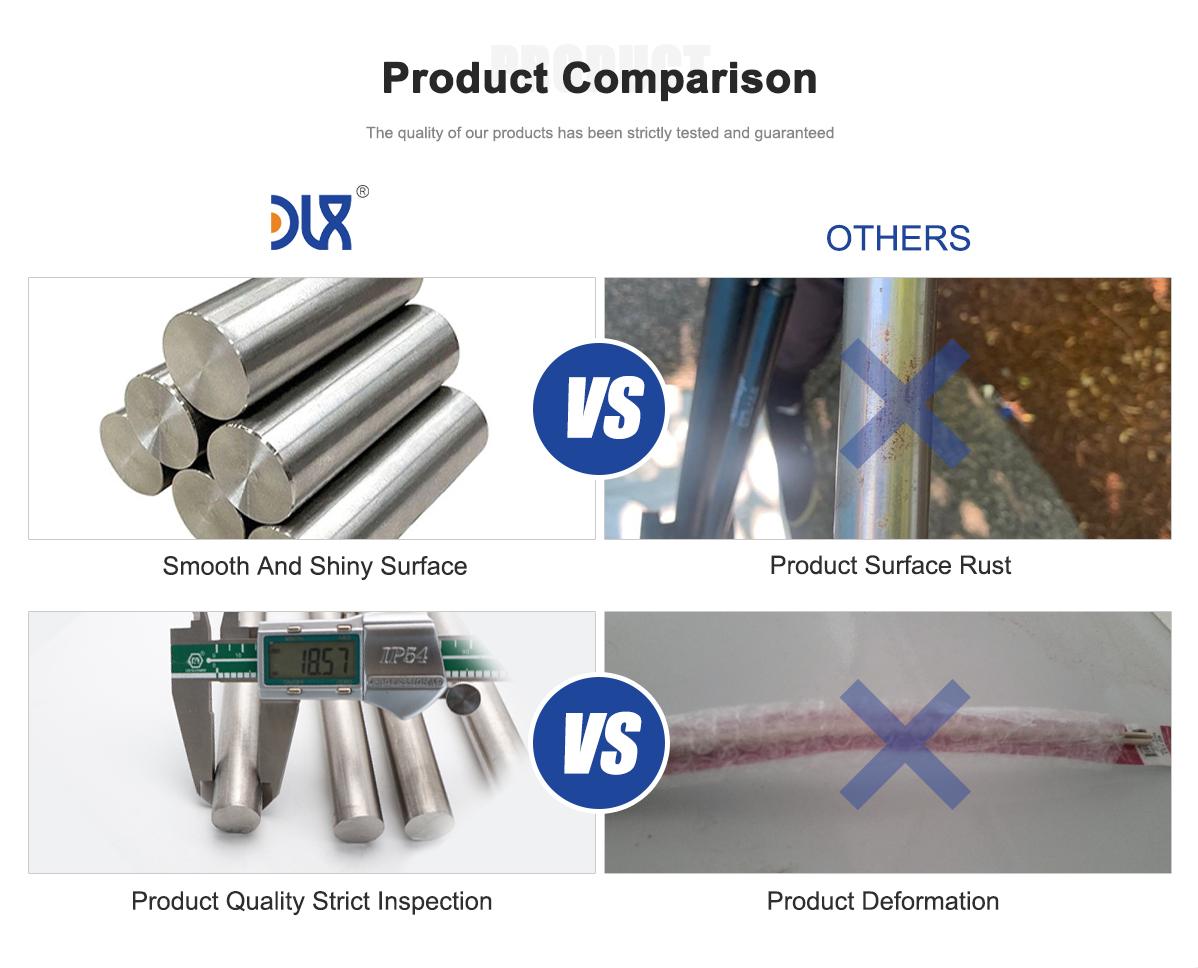

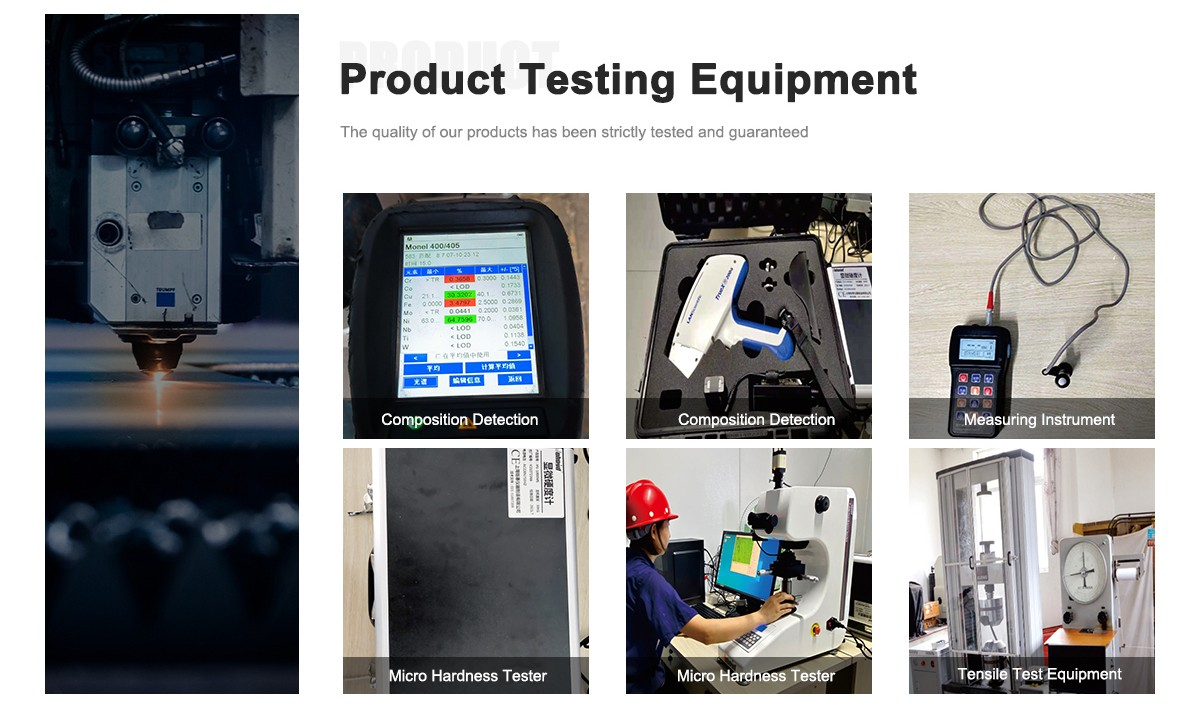

When comparing our company to others in the field, our advantages with Incoloy A-286 bar for turbine components stand out through precision and reliability. We go beyond standard supply by offering custom aging treatments that optimize high-stress resilience, achieving creep strengths 20% higher than basic specs. Our in-house testing simulates turbine conditions—think 1200°F stress rupture tests—ensuring every bar exceeds AMS 5737 standards. Lead times are quick, often under three weeks, thanks to our robust inventory, minimizing downtime for your turbine builds. Technical expertise is a game-changer; our team provides guidance on fabrication, like hot-forging at 1600-2200°F to refine grain structure without defects. While some cut corners on quality control, we adhere strictly to UNS S66286 purity, with precise titanium levels for superior precipitation hardening, leading to 25-30% extended service life in high-stress environments based on client data. This means real cost savings and fewer overhauls for your turbine components.

Digging deeper into the product, our Incoloy A-286 bar features excellent machinability with carbide tools and welds cleanly via GTAW, no preheat needed. Post-weld, we recommend aging to restore full strength, preventing sensitization. In turbine applications, its vanadium addition enhances fatigue life, making it resilient in cyclic high-stress scenarios. We process bars with boron for better hot workability, ensuring uniform properties across lengths.

Industry trends in 2025 show superalloys evolving with additive manufacturing for complex turbine parts, and our Incoloy A-286 bar is compatible, offering powder forms for 3D printing. The push for net-zero emissions boosts demand for resilient alloys in hydrogen-compatible turbines. Market reports highlight Asia's 50% share in aerospace growth, where high-stress materials like this are crucial. We've adapted by certifying our products for eco-standards, helping clients achieve sustainable turbine designs.

On applications, envision our Incoloy A-286 bar in a gas turbine shaft: it handles torque and heat without deforming, thanks to low creep rates. In commercial jets, it secures engine mounts under vibration. Power plants use it for steam turbine bolts, resisting corrosion in moist environments. Oil rigs benefit from its manifold strength in sour gas. For high-stress resilience, it's unmatched in automotive turbochargers too. We tailor diameters and finishes for precise turbine fits, enhancing overall system durability.

Our company's edge is in innovation—we enhance Incoloy A-286 bar with optional coatings for extra oxidation protection in turbine extremes. Unlike basic suppliers, we offer CAD modeling for custom profiles, cutting your development time. Pricing delivers value, with lifecycle benefits outweighing costs in 2025's market. Clients value our proactive support, from alloy selection to field troubleshooting.

Expanding on why Incoloy A-286 bar excels in turbine component high-stress resilience, its aluminum limits prevent over-aging, while molybdenum boosts corrosion resistance. In tests, it shows no embrittlement after prolonged 1300°F exposure. We ensure batch consistency with advanced spectrometry, suiting critical turbine roles.

2025 analysis reveals superalloy demand spiking with UAV and space tech, where high-stress alloys are vital. Trends include hybrid-electric propulsion, aligning with our resilient bars. We've expanded capacity to meet this, ensuring supply reliability.

Comparison Parameters Table

| Parameter | Incoloy A-286 Solution Treated Bar | Incoloy A-286 Aged Bar | Typical Precipitation-Hardening Superalloy |

|---|---|---|---|

| Tensile Strength (ksi) | 100 | 145 | 180-200 |

| Yield Strength (ksi) | 40 | 100 | 150-170 |

| Elongation (%) | 40 | 15 | 10-15 |

| Creep Rupture Strength at 1200°F (ksi for 1000h) | 20 | 30 | 25-35 |

| Oxidation Rate in Air at 1300°F (mpy) | <0.1 | <0.1 | 0.2-0.5 |

| Density (lb/in³) | 0.286 | 0.286 | 0.30 |

| Melting Range (°F) | 2500-2600 | 2500-2600 | 2300-2400 |

| Thermal Conductivity at 70°F (Btu-in/ft²•h•°F) | 80 | 80 | 70-90 |

| Applications Suitability for Turbine Components | Moderate (base strength) | High (high-stress resilience) | High (extreme temps, but higher cost) |

Applications keep expanding: in renewables, for wind turbine gears; in defense, for missile components. Energy sectors praise its sulfidation resistance. For aerospace, low thermal expansion fits precision assemblies.

In contrast, our focus on quality means rigorous NDT on every Incoloy A-286 bar, detecting flaws early for superior high-stress performance. We extend warranties based on proven turbine data, not common elsewhere. Custom variants improve weldability, reducing your costs.

Ultimately, our Incoloy A-286 bar for turbine component high-stress resilience represents peak engineering. It syncs with 2025 trends, wide applications, and unmatched durability, supported by our expertise and commitment.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Incoloy A-286 made of? Incoloy A-286 is an iron-based superalloy with 24-27% nickel, 13.5-16% chromium, 1.9-2.35% titanium, 1-1.5% molybdenum, 0.1-0.5% vanadium, up to 0.35% aluminum, 0.003-0.010% boron, up to 0.08% carbon, up to 2% manganese, up to 1% silicon, up to 0.040% phosphorus, and up to 0.030% sulfur.

What are the key mechanical properties of Incoloy A-286 bar? It offers tensile strength of 145 ksi in aged condition, yield strength of 100 ksi, elongation of 15%, with excellent creep-rupture strength over 10,000 hours at 1200°F under 30 ksi stress, and maintains ductility in notched sections.

How does Incoloy A-286 resist high stress in turbine components? It provides age-hardenable strengthening through precipitation of gamma prime phases, offering high fatigue resistance, low creep rates under 0.0001%/hour at 1300°F, and superior notched rupture strength to prevent failure in high-stress turbine environments.

What are common applications for Incoloy A-286 bar? It's used in turbine engine components, jet engine fasteners, afterburner parts, supercharger wheels, oil and gas manifolds, cryogenic equipment, springs, and automotive exhaust valves.

How does Incoloy A-286 perform in turbine components? In turbine discs, blades, and shafts, it withstands temperatures up to 1300°F with oxidation resistance below 0.1 mpy, resisting thermal fatigue and maintaining high-stress resilience in cyclic loading conditions.

What industry trends are driving the use of Incoloy A-286 in 2025? Superalloy market grows from $7.82 billion in 2025 at 12.4% CAGR to $17.75 billion by 2032, driven by aerospace turbine advancements, sustainable energy transitions, and demand for high-stress resilient materials in Asia-Pacific.

How is Incoloy A-286 bar fabricated? Solution treated at 1800°F, aged at 1325°F for 16 hours, hot-forged at 1600-2200°F, machined with carbide tools, and welded using GTAW without preheat, followed by post-weld heat treatment.

What makes Incoloy A-286 suitable for high-temperature applications? It retains mechanical properties up to 1300°F with thermal conductivity of 80 Btu-in/ft²•h•°F at 70°F, melting range 2500-2600°F, and resistance to oxidation and embrittlement, ideal for prolonged high-stress exposure.